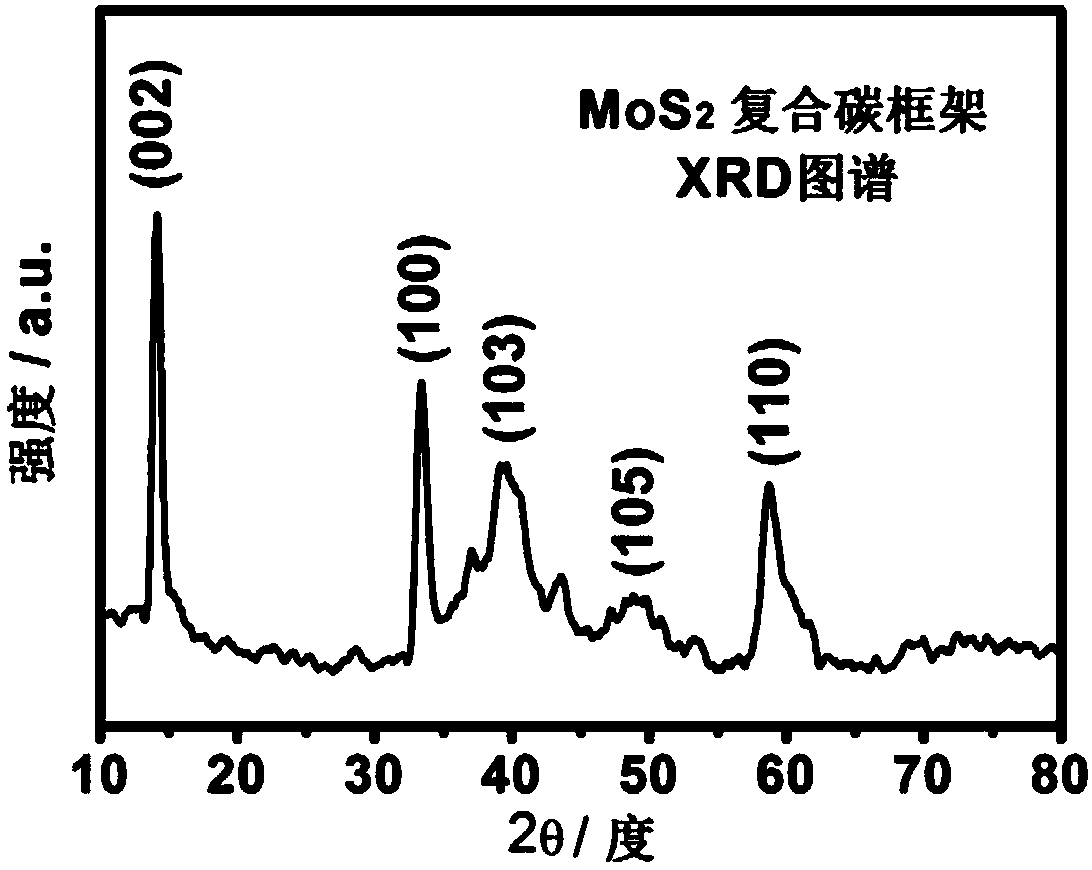

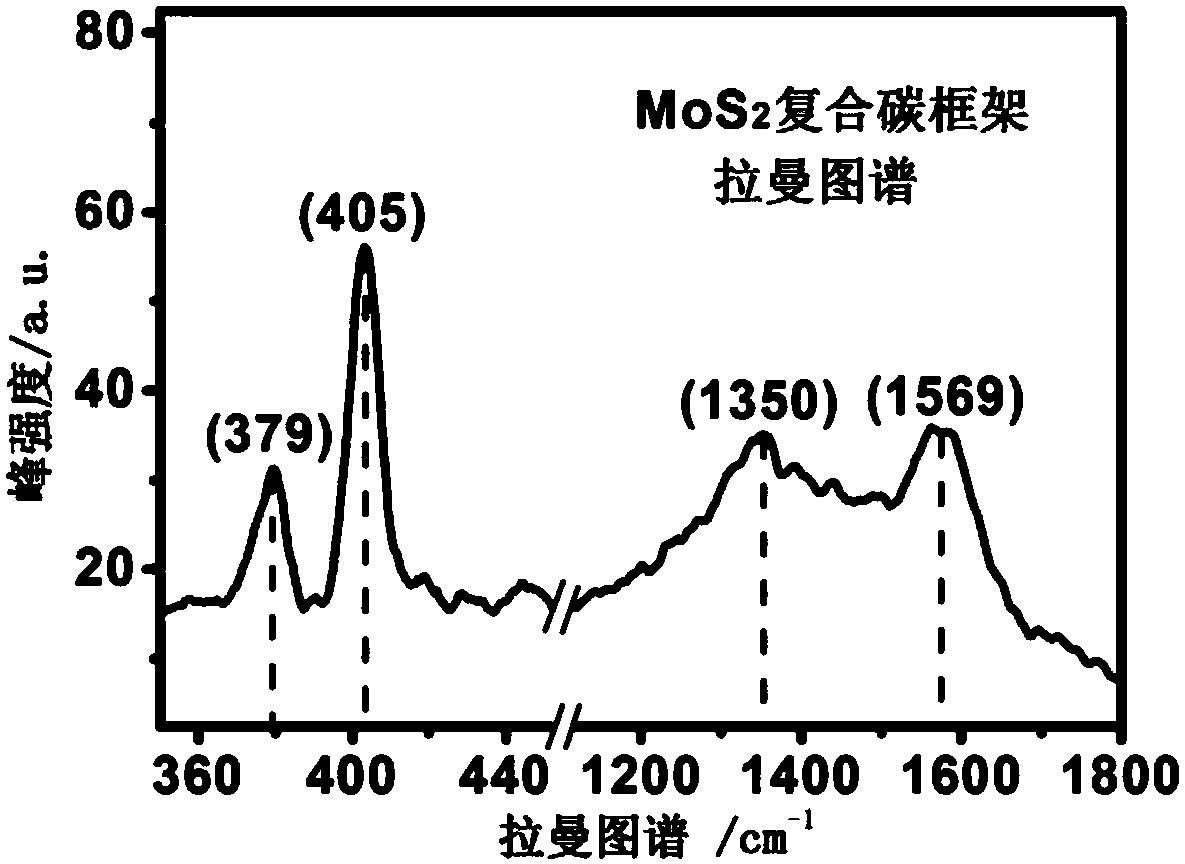

Carbon frame nanoribbons equipped with mos 2 Nanosphere nanocomposite material and preparation method thereof

A nano-composite material and nano-sphere technology are applied in the field of layered MoS2 nano-sphere material preparation and lithium ion battery anode material field to achieve the effects of large electric capacity, enhanced stability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Preparation of onion-layered MoS on radial carbon frame nanoribbons 2 nanosphere nanocomposite

[0047] The specific steps of preparation are as follows:

[0048] (1) Dissolve 0.8g of sodium molybdate, 1.5g of thioacetamide, and thioacetamide in 120mL of deionized water, add about 0.8g of oxalic acid to adjust the pH of the solution, and stir well.

[0049] (2) After stirring for more than 30 minutes, add the mixed solution into a 150mL reaction kettle, seal it, then put it into an oven and heat it at 200°C for 24 hours, and cool to room temperature after the reaction is completed.

[0050] (3) Collect and remove the black precipitate at the bottom of the reaction kettle and the black adhesion on the inner wall, and wash it repeatedly with deionized water until the supernatant is completely clear.

[0051] (4) Pour off the supernatant, put the pure sample in a vacuum oven at 60° C. for 5 hours and take it out after drying to obtain a black powder.

[0052] ...

Embodiment 2

[0055] Example 2 Radial carbon frame nanobelts of the present invention equipped with onion-layered MoS 2 Performance testing of nanosphere nanocomposites as anode materials for lithium-ion batteries

[0056] Onion-layered MoS mounted on radial carbon frame nanoribbons prepared in Example 1 above 2 Nanosphere nanocomposite due to its large storage capacity of MoS 2 As the main material, nanospheres have a relatively stable carbon nanostructure, and carbon nanomaterials can further improve the conductivity of the material, making it comparable to other MoS 2 Nanomaterials have significant advantages in the application performance of lithium-ion battery anode materials. Onion layered MoS mounted on the radial carbon frame nanoribbon of the present invention 2 The performance test of the nanosphere nanocomposite material as the anode material of the lithium ion battery includes the following specific steps:

[0057] (1) Take the radial carbon frame nanoribbon of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com