Flexible self-supporting tellurium nanotube composite electrode, preparation method thereof and flexible battery

A composite electrode, tellurium nanotechnology, applied in the direction of battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of reducing the overall energy density of flexible devices, limiting the flexibility of electrodes, and mutual constraints, so as to achieve easy assembly into films and improve capacity Insufficient, the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A flexible self-supporting tellurium nanotube composite electrode, the preparation method of which comprises the following four steps of S1, S2, S3 and S4:

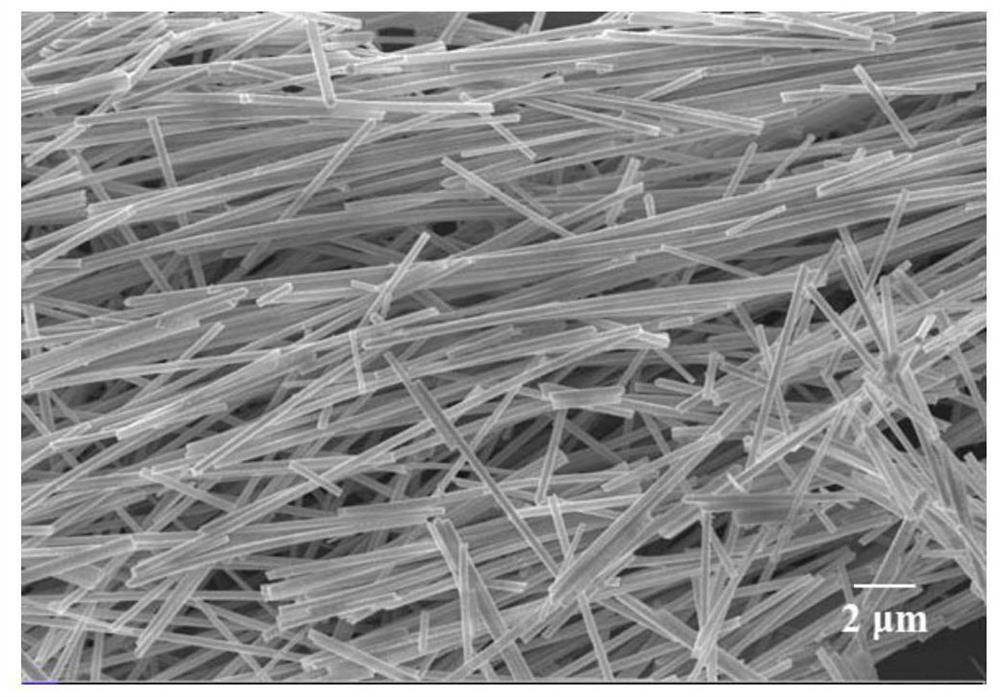

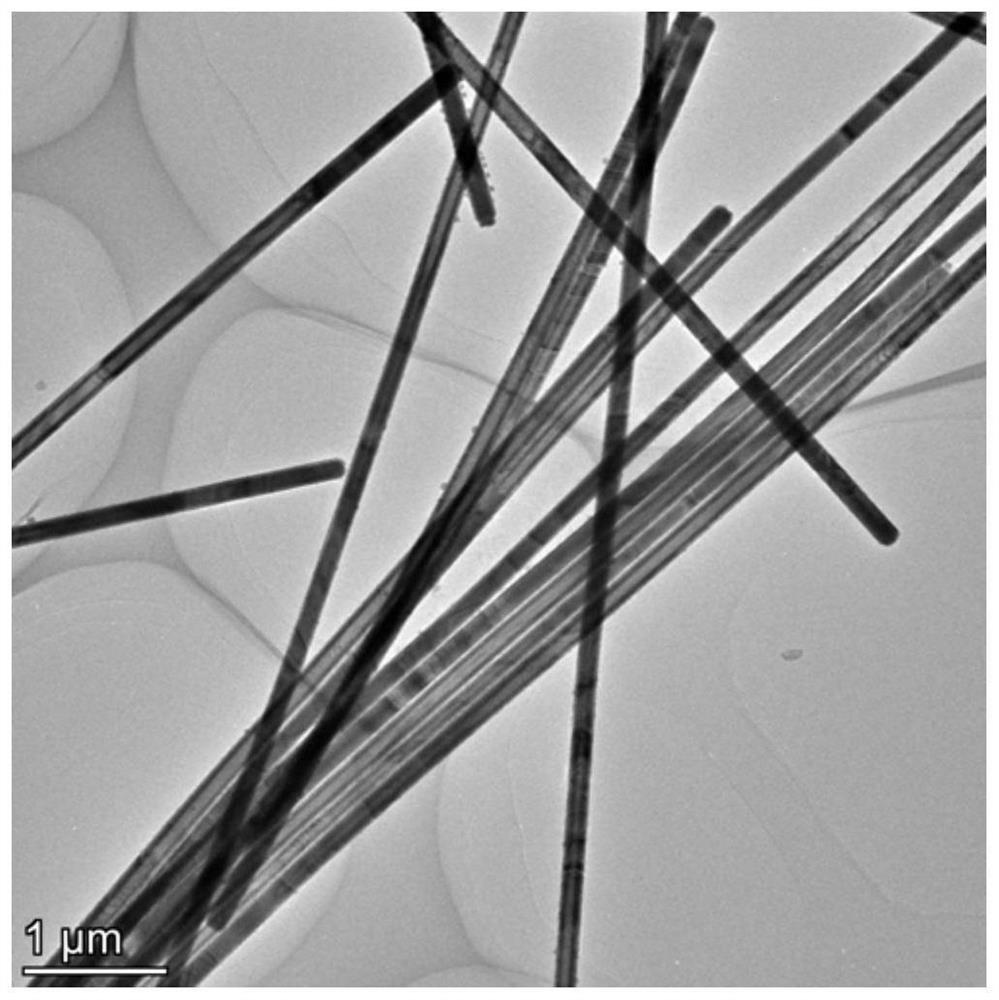

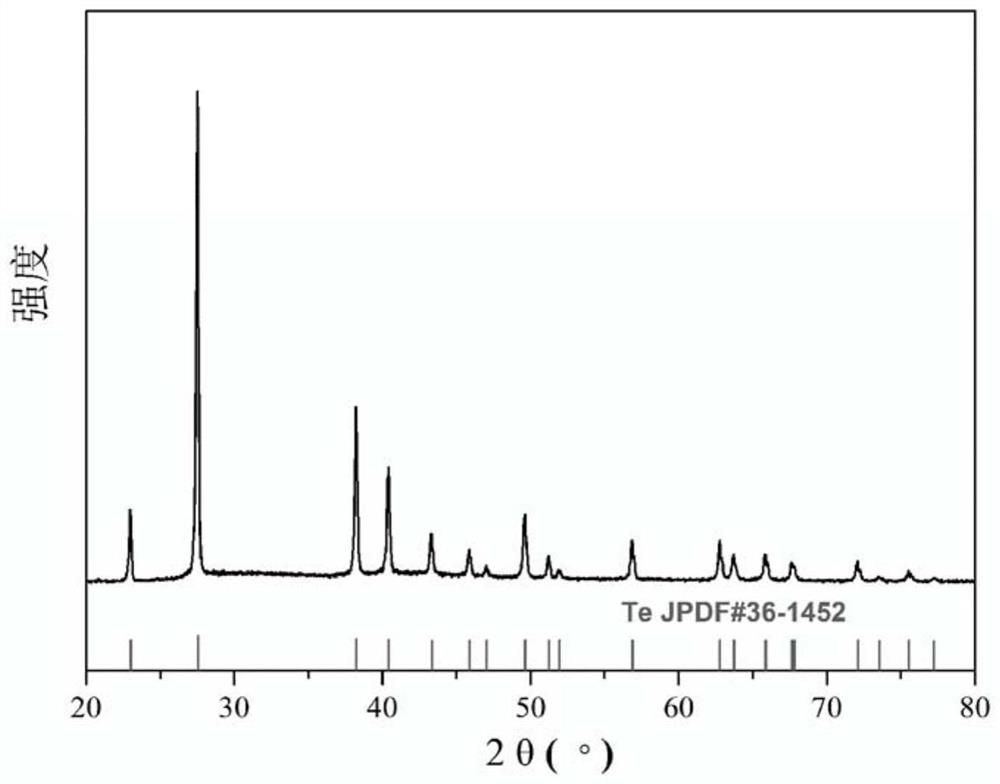

[0043] S1, Polymer-assisted solvothermal preparation of tellurium nanotubes:

[0044] Take 0.25g Na 2 TeO 3 and 3g of PVP, dissolved in 150ml of ultrapure water and stirred for 10min, then added 50ml of acetone and continued to stir for 10min, finally added 15ml of ammonia water and 7.5ml of hydrazine hydrate and stirred for 20min. The obtained mixed solution was divided into five parts, added to five reaction kettles with polytetrafluoroethylene liners with a capacity of 50 ml, and then the reaction kettles were transferred to an oven at 180° C. for 4 hours. After the reaction solution was naturally cooled, the supernatant was poured out, and the obtained precipitate was washed with ultrapure water and centrifuged. After repeating three times, the precipitate was collected and dried in a blast drying oven at 80°...

Embodiment 2

[0053] A flexible self-supporting tellurium nanotube composite electrode, the preparation method of which comprises the following four steps of S1, S2, S3 and S4:

[0054] S1, Polymer-assisted solvothermal preparation of tellurium nanotubes:

[0055] Take 0.25g Na 2 TeO 3 and 2.5g of PVP, dissolved in 125ml of ultrapure water and stirred for 10min, then added 50ml of acetone and continued to stir for 10min, finally added 15ml of ammonia water and 7.5ml of hydrazine hydrate and stirred for 20min. The obtained mixed solution was divided into five parts, added to five reaction kettles with polytetrafluoroethylene liners with a capacity of 50 ml, and then the reaction kettles were transferred to an oven at 180° C. for 4 hours. After the reacted solution was naturally cooled, the supernatant was poured out, and the obtained precipitate was washed three times with ultrapure water, centrifuged, collected and placed in a blast drying oven at 80° C. for 8 hours to obtain tellurium na...

Embodiment 3

[0064] A flexible self-supporting tellurium nanotube composite electrode, the preparation method of which comprises the following four steps of S1, S2, S3 and S4:

[0065] S1, Polymer-assisted solvothermal preparation of tellurium nanotubes:

[0066] Take 0.25g Na 2 TeO 3 and 2g of PVP, dissolved in 50ml of ultrapure water and stirred for 10min, then added 50ml of acetone and continued to stir for 10min, finally added 7.5ml of ammonia water and 3.75ml of hydrazine hydrate and stirred for 20min. The obtained mixed solution was transferred and divided into five parts, which were added to five reaction kettles with polytetrafluoroethylene liners with a capacity of 50 ml, and then the reaction kettles were transferred to an oven at 200° C. for 3 hours. After the reaction solution was naturally cooled, the supernatant was poured out, and the obtained precipitate was washed with ultrapure water and centrifuged. After repeating three times, the precipitate was collected and dried i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com