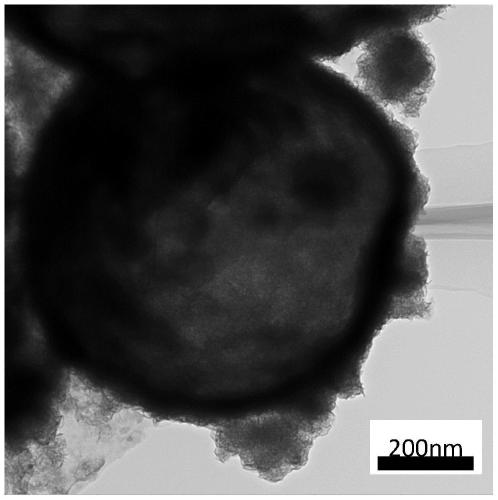

A kind of preparation method of molybdenum selenide two-dimensional layered titanium carbide composite material

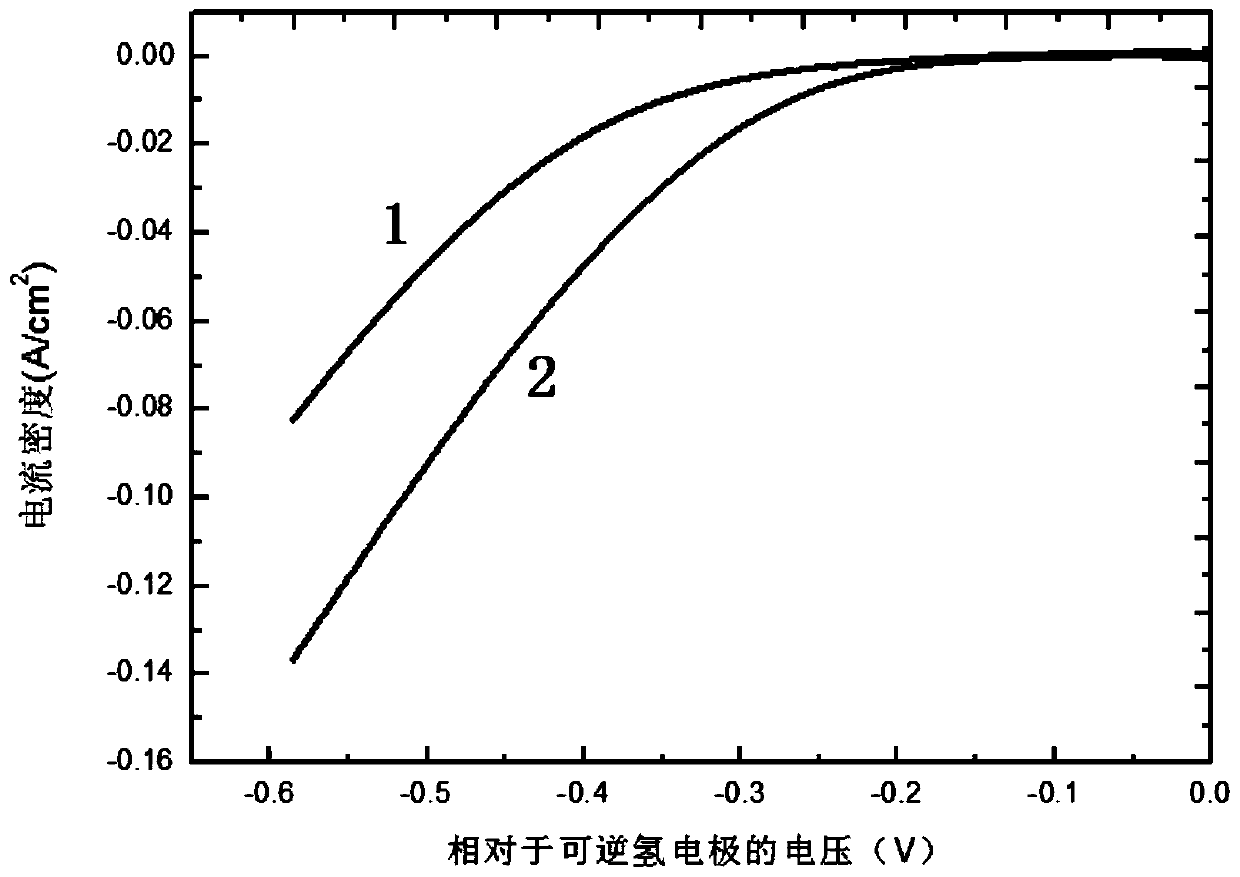

A two-dimensional layered and composite material technology, applied in structural parts, electrolytic components, electrolytic processes, etc., can solve the problems of poor conductivity and low ion mobility of molybdenum selenide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] Embodiment 1: In this embodiment, a method for preparing a molybdenum selenide two-dimensional layered titanium carbide composite material is carried out according to the following steps:

[0032] 1. Mix and stir Se powder and hydrazine hydrate with a mass percentage of 97% to 98% for 12h to 24h to obtain a selenium-hydrazine hydrate dispersion;

[0033] The molar ratio of the Se powder to the mass percentage of hydrazine hydrate of 97% to 98% is (0.8 to 1.3) mmol: 5 mL;

[0034] Second, the MXene-Ti 3 C 2 Mix the dispersion with cetyltrimethylammonium bromide, stir for 0.5h to 2h at a temperature of 30°C to 50°C, add sodium molybdate and stir for 0.2h to 2h to obtain hexadecyltrimethylammonium bromide ammonium bromide solution;

[0035] The MXene-Ti 3 C 2 The mass ratio of the volume of dispersion liquid and cetyltrimethylammonium bromide is (10~50) mL:1g; Described MXene-Ti 3 C 2 The molar ratio of the volume of dispersion liquid to sodium molybdate is (10~15)m...

specific Embodiment approach 2

[0055] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the molar and mass percentage of the Se powder described in the step one is that the volume ratio of hydrazine hydrate of 97%~98% is (0.8~1) mmol: 5mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0056] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the MXene-Ti described in step two 3 C 2 The mass ratio of the volume of dispersion liquid and cetyltrimethylammonium bromide is (10~40) mL:1g; The MXene-Ti described in step 2 3 C 2 The molar ratio of the volume of the dispersion to sodium molybdate is (10-12) mL:1 mmol. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com