Porous sulfide/graphene composite electrode material for super capacitor and preparation method thereof

A composite material and graphene technology, which is applied in the fields of environmental protection, electrochemistry, energy storage, materials, and chemical industry, can solve the problems of low specific surface area of electrode materials, poor electrochemical performance of composite materials, and low capacitance, etc., and achieve uniform, stable and reliable controlled synthesis, good electrical conductivity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare graphene oxide in advance (or synthesize graphene oxide with graphite powder or graphite oxide) or reduce graphene oxide for later use.

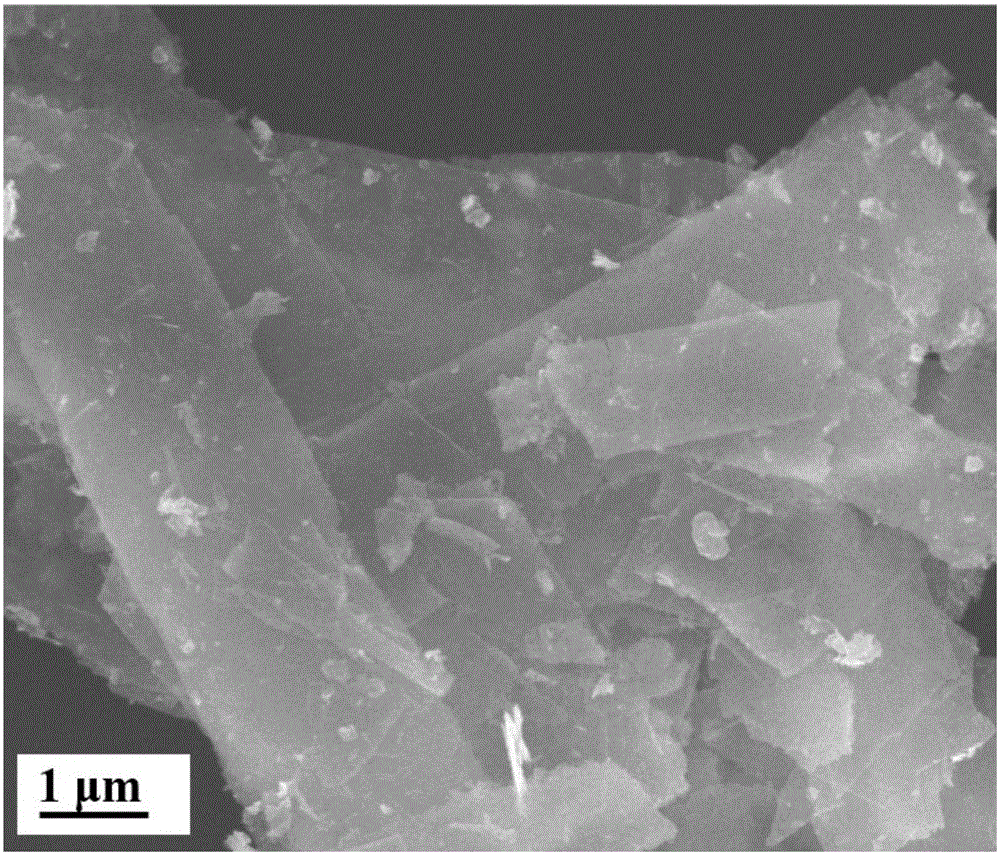

[0029] First disperse 45mg graphene oxide in 15ml deionized water. 0.5mmol Cu(OAC)·H 2 O,1mmol Co(OAC)·4H 2 O was dissolved in 15ml of absolute ethanol and ultrasonically treated for 30min. The above metal salt solution was slowly added dropwise into the graphene oxide dispersion. After magnetic stirring for 30min, 72mgNa was added dropwise 2 CO 3 (dissolved in 2ml deionized water), continue to stir for 30min, and then add 1.0-2.0ml (1.5ml is a better value) triethylamine dropwise. After 1 h, the mixed solution was transferred to a polytetrafluoroethylene reactor for hydrothermal synthesis reaction, and heated at 180° C. for 12 h. After the reactor was naturally cooled to room temperature, the obtained samples were washed with deionized water and absolute ethanol, and dried at 70°C for 3 hours to obtain a graphene-copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mesopore | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com