High-nickel positive electrode material with uniform coating layer and preparation method thereof

A technology for positive electrode materials and coating materials, which is applied in the field of high-nickel positive electrode materials and its preparation, can solve the problems of reducing the active lithium content of positive electrode materials and reducing energy density, so as to reduce production costs and time, avoid excessive loss, and improve The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

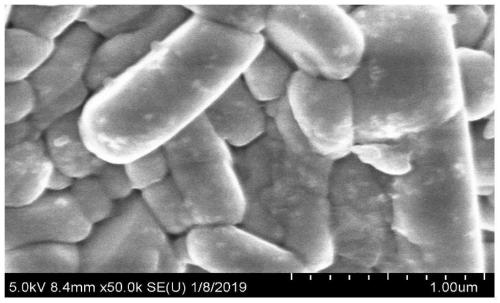

[0046] The cathode active material LiNi 0.88 co 0.09 mn 0.03 o 2 1kg and 2.89g of nano-alumina, 2.33g of lithium hydroxide monohydrate are ball milled and stirred evenly, sieved, placed in a sagger, and sintered at 560°C for 6 hours in a preheated muffle furnace oxygen atmosphere (oxygen concentration ≥ 80%) . Cool slowly, crush and sieve to obtain a positive electrode material active material with a uniform coating layer.

Embodiment 2

[0048] The cathode active material LiNi 0.80 co 0.10 mn 0.10 o 2 1kg and 3.49g of nano-zirconia, 2.33g of lithium hydroxide monohydrate, ball mill and stir evenly, sieve, place in a sagger, and sinter at 720°C for 7h in a preheated muffle furnace oxygen atmosphere (oxygen concentration ≥ 80%) . Cool slowly, crush and sieve to obtain a positive electrode material active material with a uniform coating layer.

Embodiment 3

[0050] The cathode active material LiNi 0.80 co 0.10 mn 0.10 o 2 1kg and 5.31g of nano-gallium oxide, 2.33g of lithium hydroxide monohydrate are ball milled and stirred evenly, sieved, placed in a sagger, and sintered at 500°C for 4 hours in a preheated muffle furnace oxygen atmosphere (oxygen concentration ≥ 80%) . Cool slowly, crush and sieve to obtain a positive electrode material active material with a uniform coating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com