Production method of freshness-retaining spicy cabbage fried rice and freshness-retaining spicy cabbage fried rice

A production method, the technology of spicy cabbage, which is applied in the field of food processing, can solve the problems of low content of animal protein and plant fiber, monotonous taste, and large gap, so as to avoid the decline of integrity and compactness, prevent external diffusion, and reduce steam pressure. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. Microwave heating: quickly wash the rice with cold water and hot water successively, drain and put it into a container, add hot water, and use microwave heating; B. Sealing: add hot seasoning material soaking liquid to the mixture obtained in step A , stir evenly and lay flat, the rice and seasoning materials do not exceed the edge of the container, fill with nitrogen, and seal; C: Autoclave: sterilize the sealed rice in a water bath at high temperature and high pressure; the seasoning materials described in step B include dehydrated spicy Cabbage and salt, the ratio of raw materials is 150 parts of rice in mass parts, 1 part of dehydrated spicy cabbage and 1 part of salt.

[0030] In the step C, the rice is sealed with nitrogen gas by using a film sealing machine, and the temperature of the film sealing machine is 150°C.

[0031] In step D, the sealed box is sterilized in a water bath in a sterilizer, and the steps include water injection, temperature rise, heat pre...

Embodiment 2

[0041] The difference with embodiment 1 is:

[0042] The ratio of raw materials is 60 parts of rice, 10 parts of dehydrated spicy cabbage and 4 parts of salt in terms of mass parts.

[0043] The microwave power of the microwave heating described in step B is 6.5kw, and the time is 120s.

[0044] In the step A, the weight ratio of the original weight of rice to water in the system after adding hot water is 1:1.

[0045] In the step C, the ratio of the original weight of rice in the system to the sum of the weight of water and the seasoning material soaking solution after supplementing the hot seasoning material soaking solution is 1:2.0.

[0046] The preparation method of the seasoning material soaking liquid described in step C is as follows: soak the seasoning material in hot water above 60°C, keep warm at above 60°C for 3.0h, heat to 90°C when in use, and mix the solid and The liquids are added together to the mixture obtained in step A.

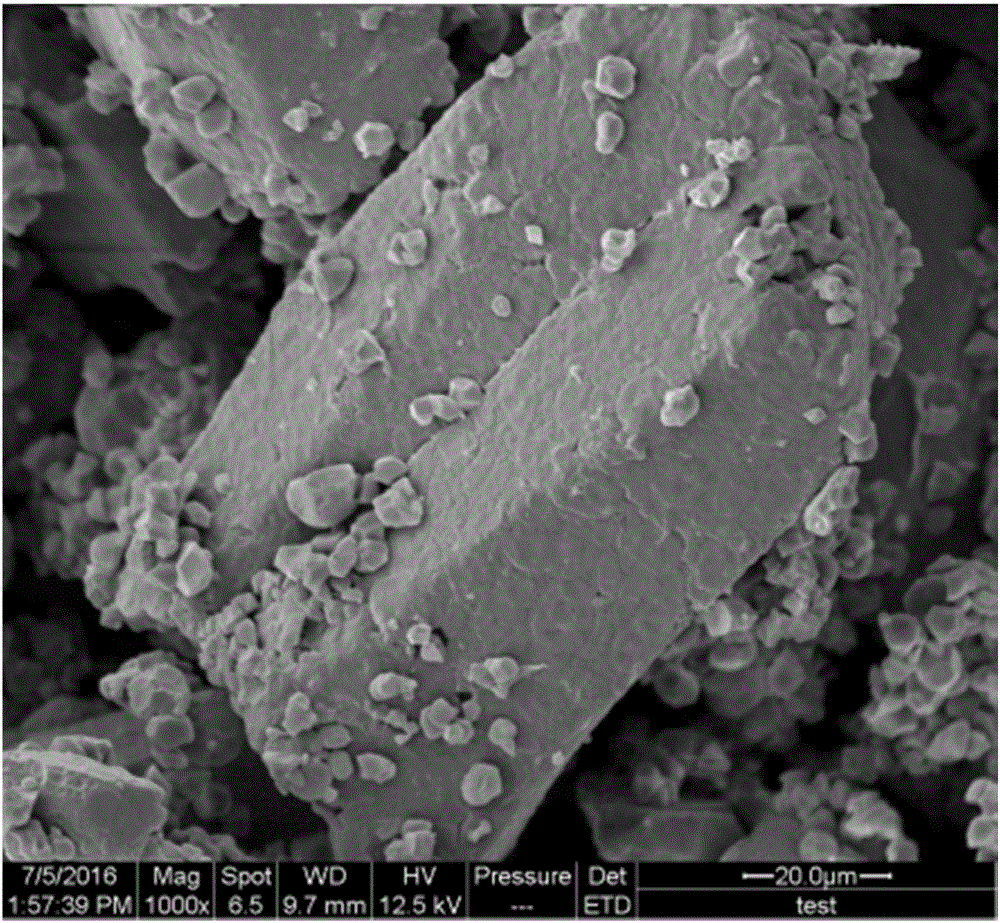

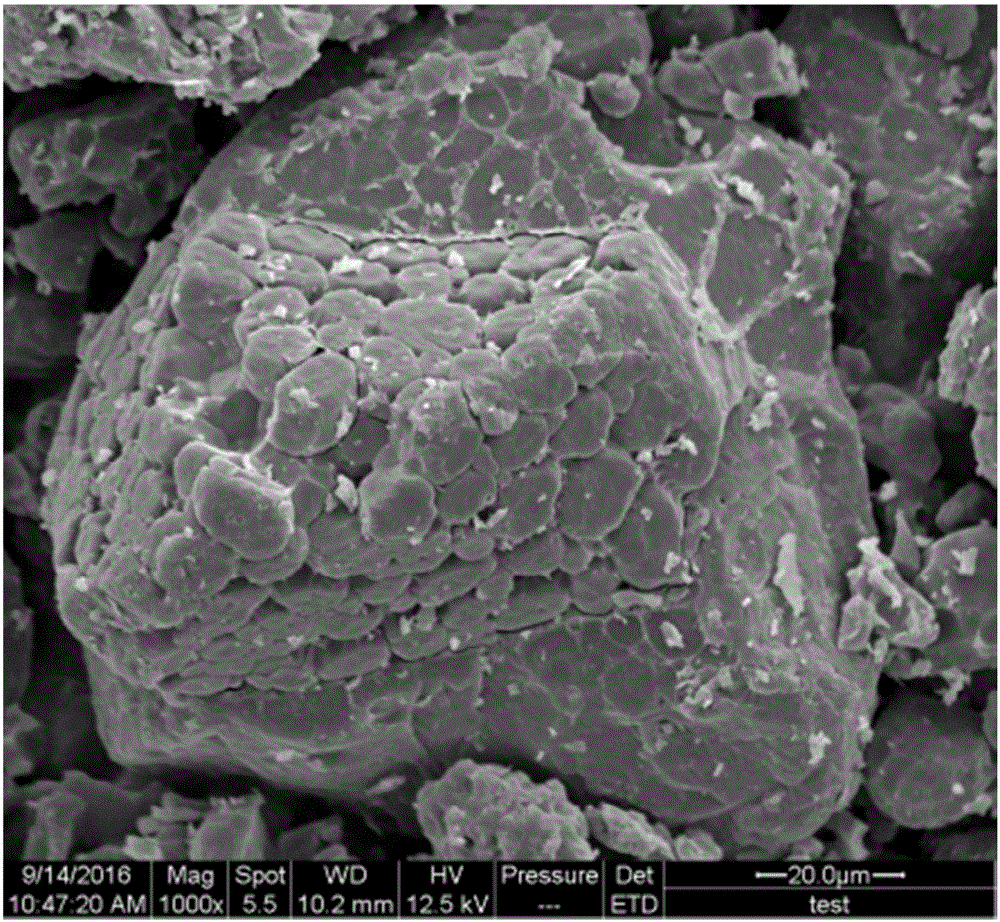

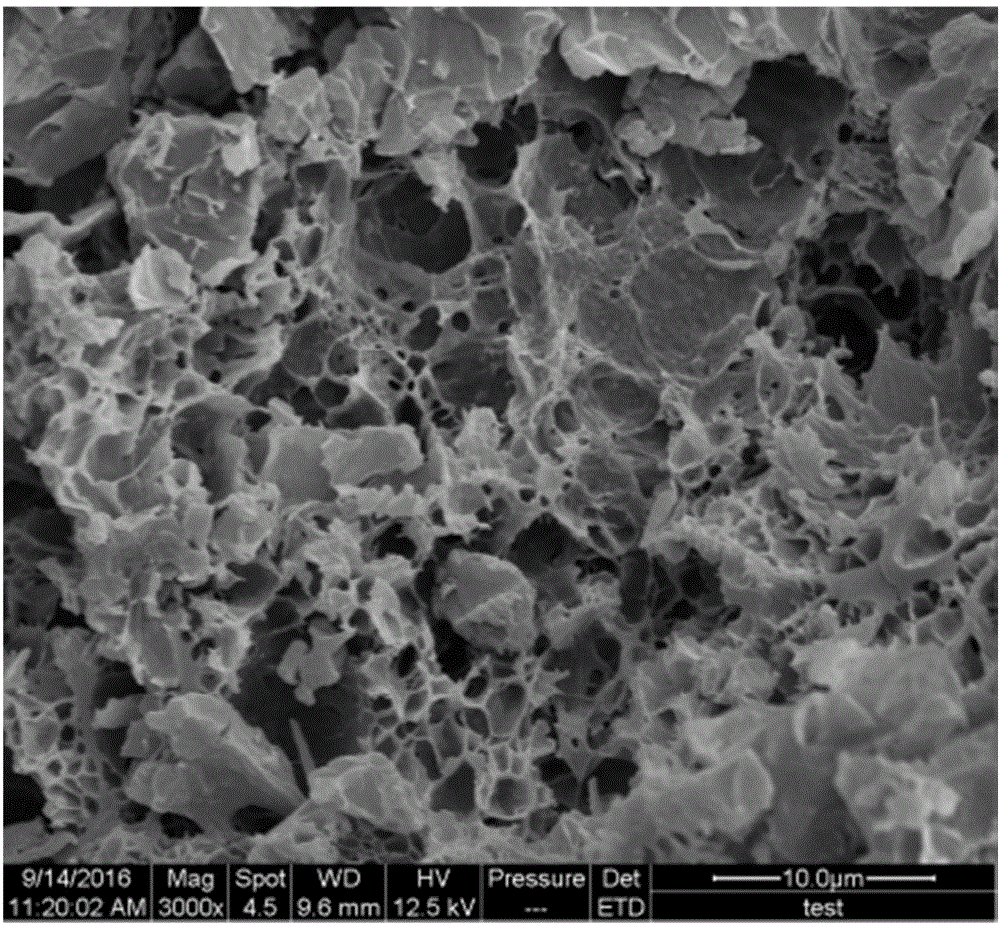

[0047] The particle diameter of ...

Embodiment 3

[0051] A. Microwave heating: quickly wash the rice with cold water and hot water successively, drain and put it into a container, add hot water, and use microwave heating; B. Sealing: add hot seasoning material soaking liquid to the mixture obtained in step A , stir evenly and spread the rice so that the rice does not exceed the edge of the container, fill it with nitrogen, and seal it; C: Autoclave: Sterilize the sealed rice at high temperature and high pressure in a water bath; the raw material ratio is calculated as rice 90% by mass. 7 parts of dehydrated spicy cabbage, 4 parts of salt.

[0052] In the step C, the rice is sealed with nitrogen gas by using a film sealing machine, and the temperature of the film sealing machine is 190°C.

[0053] In step D, the sealed box is sterilized in a water bath in a sterilizer, and the steps include water injection, temperature rise, heat preservation, hot water recovery, cooling water injection, cooling cycle, and drainage and exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com