Composite negative electrode of solid-state lithium battery and preparation method of composite negative electrode

A solid-state lithium and lithium negative electrode technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of poor conductivity and low safety, and achieve the effect of enhancing wettability and improving battery short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

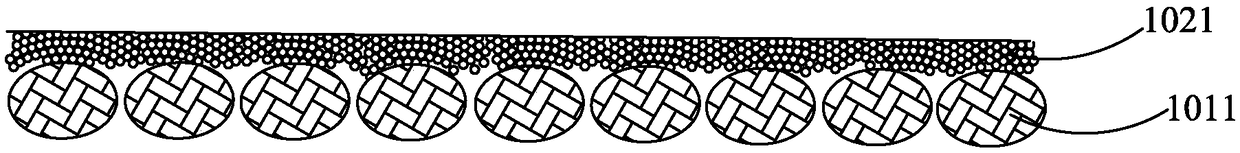

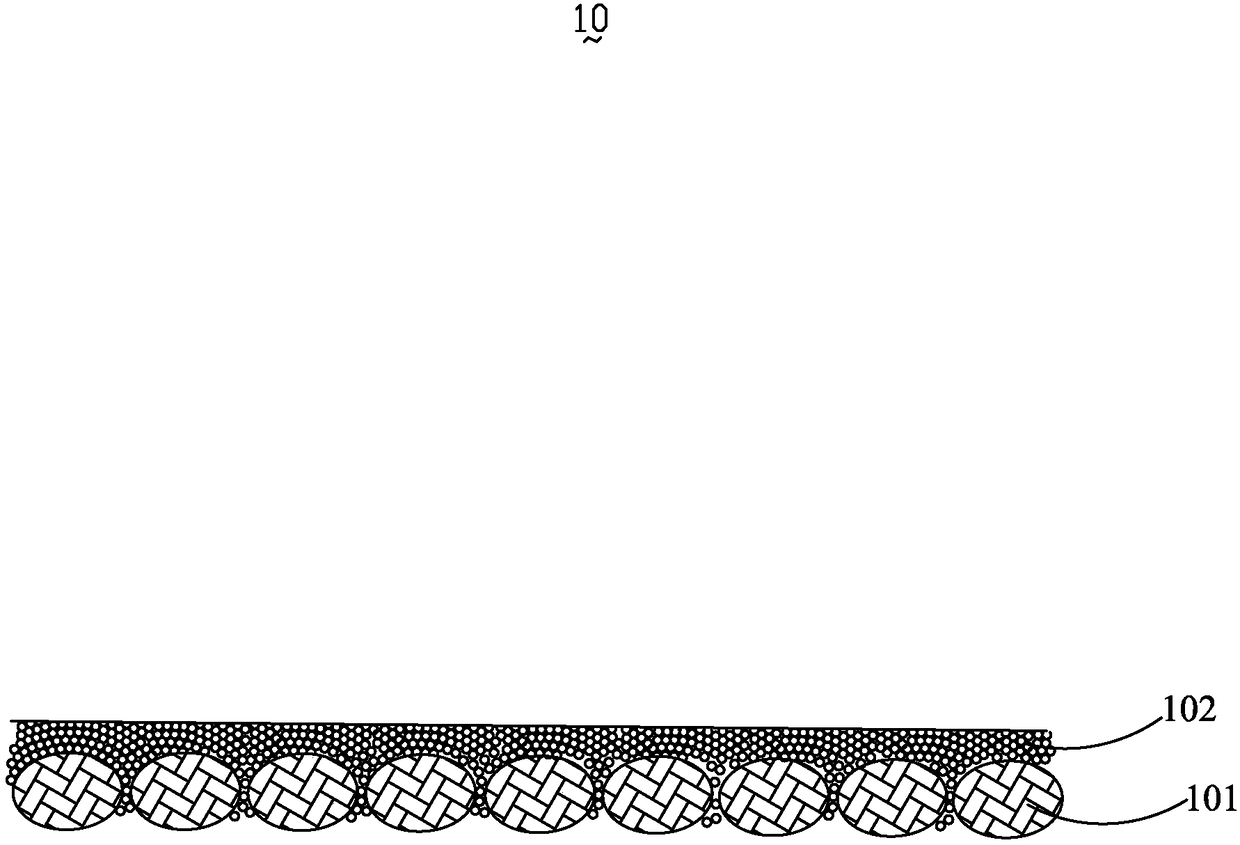

[0027] see figure 2 , the first embodiment, a solid-state lithium battery composite negative electrode 10, including a solid electrolyte film layer 101 and a lithium negative electrode layer 102, the lithium negative electrode layer 102 includes a lithium metal negative electrode material, and the lithium metal negative electrode material is combined in a molten state A lithium negative electrode layer 102 is formed on the solid electrolyte film layer 101, and the solid electrolyte film layer 101 includes an electrolyte material. The electrolyte material includes garnet-structured Li 7 La 3 Zr 5 o 12 or the Li 7 La 3 Zr 5 o 12 The doping modified substance, the Li 7 La 3 Zr 5 o 12 The doping modifying element can be any one of Ca, Nb and Ta.

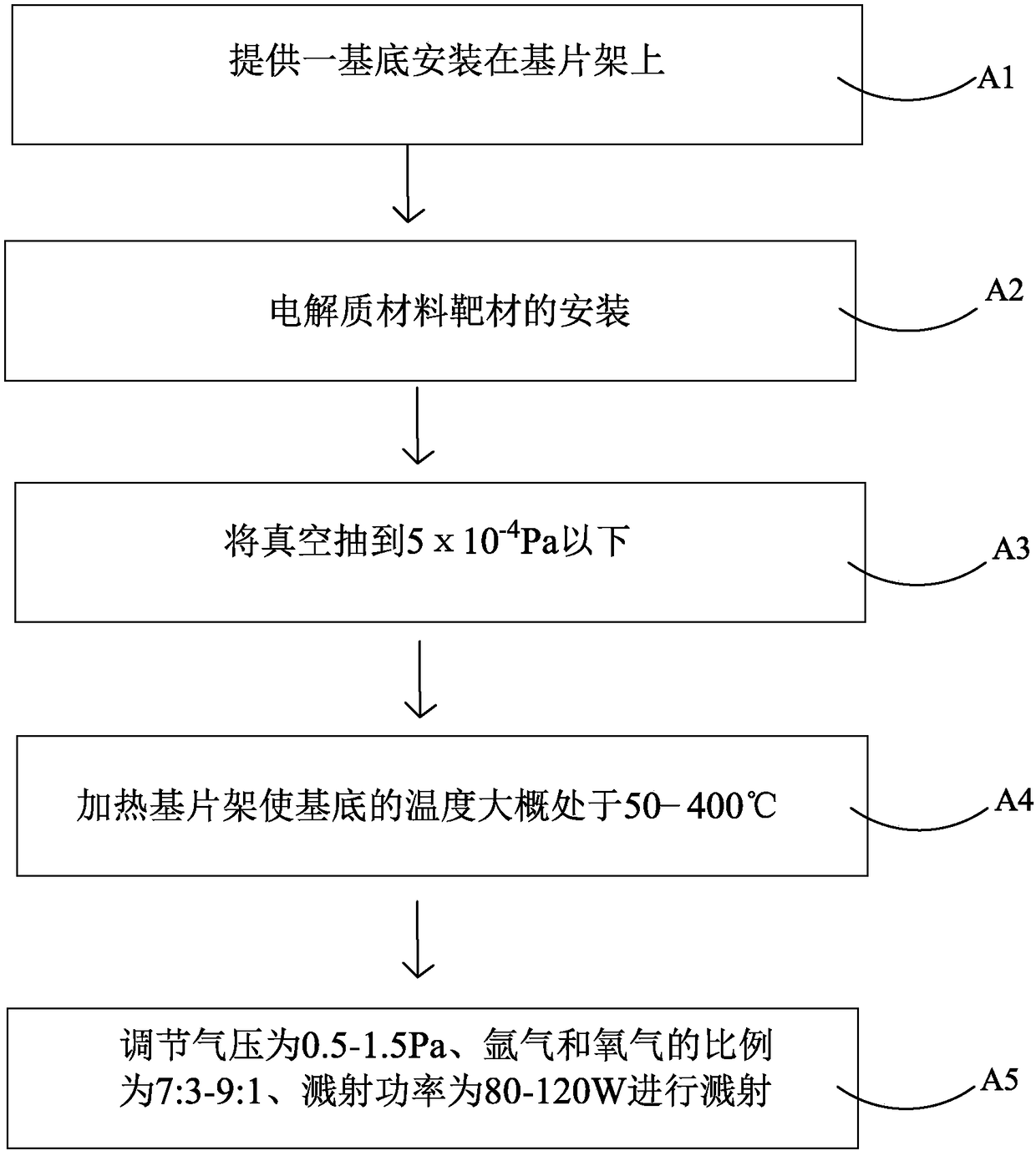

[0028] A method for preparing a composite negative electrode of a solid-state lithium battery. First, the electrolyte material is synthesized by a solid-phase synthesis method, and then a substrate is provided, and the elect...

no. 2 example

[0075] For a second example, see Figure 9 , a solid lithium battery composite negative electrode 20, including a solid electrolyte film layer 101 and a lithium negative electrode layer 102, the lithium negative electrode layer 102 and the solid electrolyte film layer 101 are melt-fitted, and the solid electrolyte film layer 101 includes an electrolyte material. A buffer layer 103 is also formed on the solid electrolyte film layer 101, the buffer layer 103 is located between the solid electrolyte film layer 101 and the lithium negative electrode layer 102, and the buffer layer 103 includes lithium-philic oxides, polymers Or gel electrolyte buffer layer material.

[0076] The formation method of the solid electrolyte film layer 101 in this embodiment is the same as that in the first embodiment, and includes the same electrolyte material as in the first embodiment.

[0077] read on Figure 9 , using the solid electrolyte thin film layer 101 as a base, depositing the buffer str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com