Preparation method for nanoscale lithium titanate material with high specific capacity

A high specific capacity, nano-scale technology, applied in the direction of titanate, nanotechnology, nanotechnology, etc., can solve the problems of not taking into account performance, etc., to achieve the effect of shortening the processing time, wide selection range, and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the high specific capacity nanoscale lithium titanate material provided by the present invention comprises the following steps:

[0031] (1) Preparation of liquid A:

[0032] Disperse the titanium compound into 50-500ml of deionized water to obtain liquid A;

[0033] (2) Preparation of liquid B:

[0034] Disperse the lithium compound into 50-500ml of deionized water, wherein the ratio of the amount of lithium in the lithium compound to the amount of titanium in the titanium compound in step (1) is: n Li :n Ti =1:1.0~1.2, you can get liquid B;

[0035] (3) Slowly add liquid B to liquid A, and at the same time carry out magnetic stirring, and stir for 30 minutes to obtain a mixed dispersion;

[0036] (4) Put the mixed dispersion liquid obtained in step (3) into a high-temperature reaction kettle, and then place it in an oven at 120-200°C for 5-24 hours. After washing with deionized water or absolute ethanol, dry at a temperature of 60-120°C ...

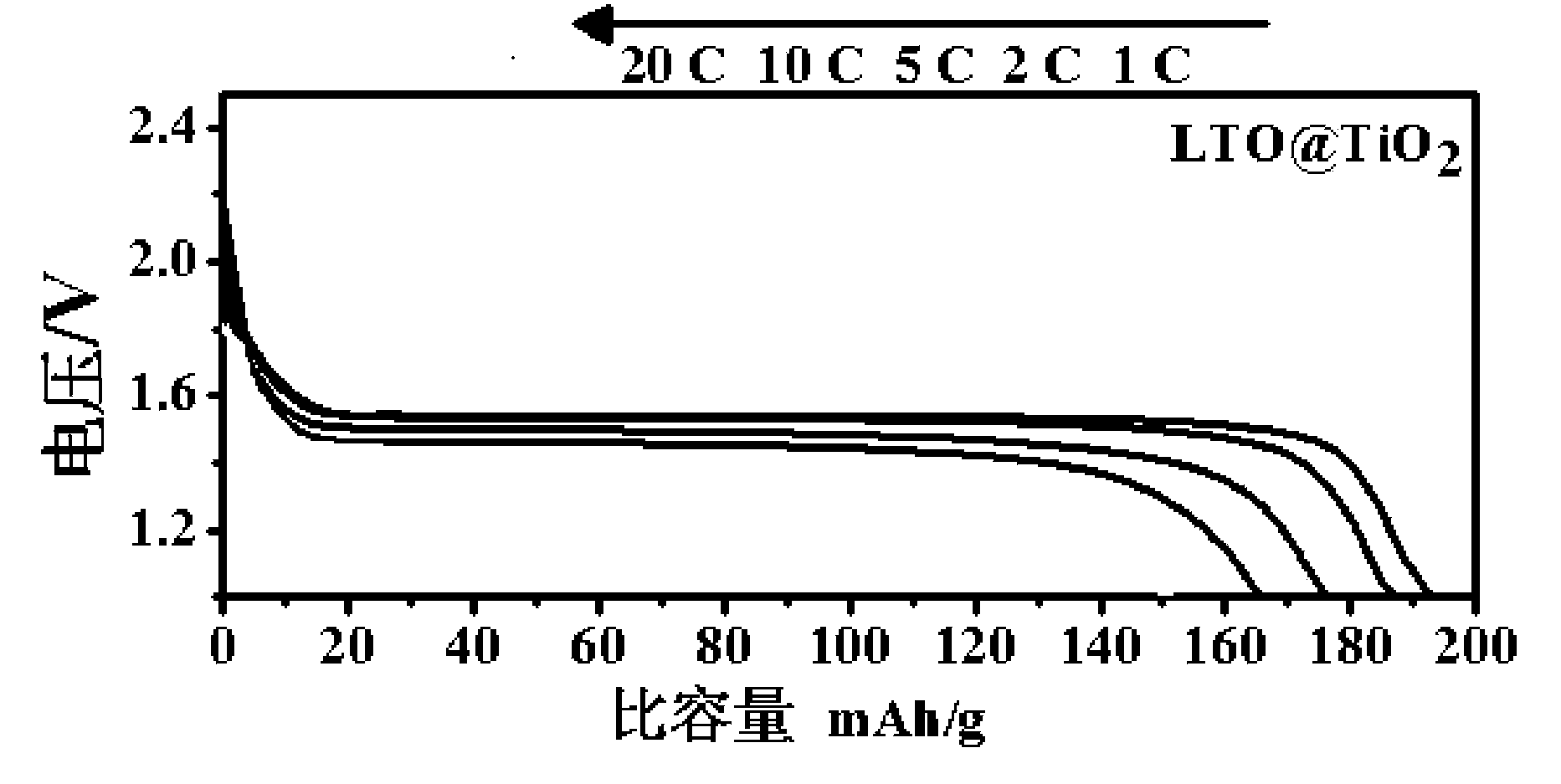

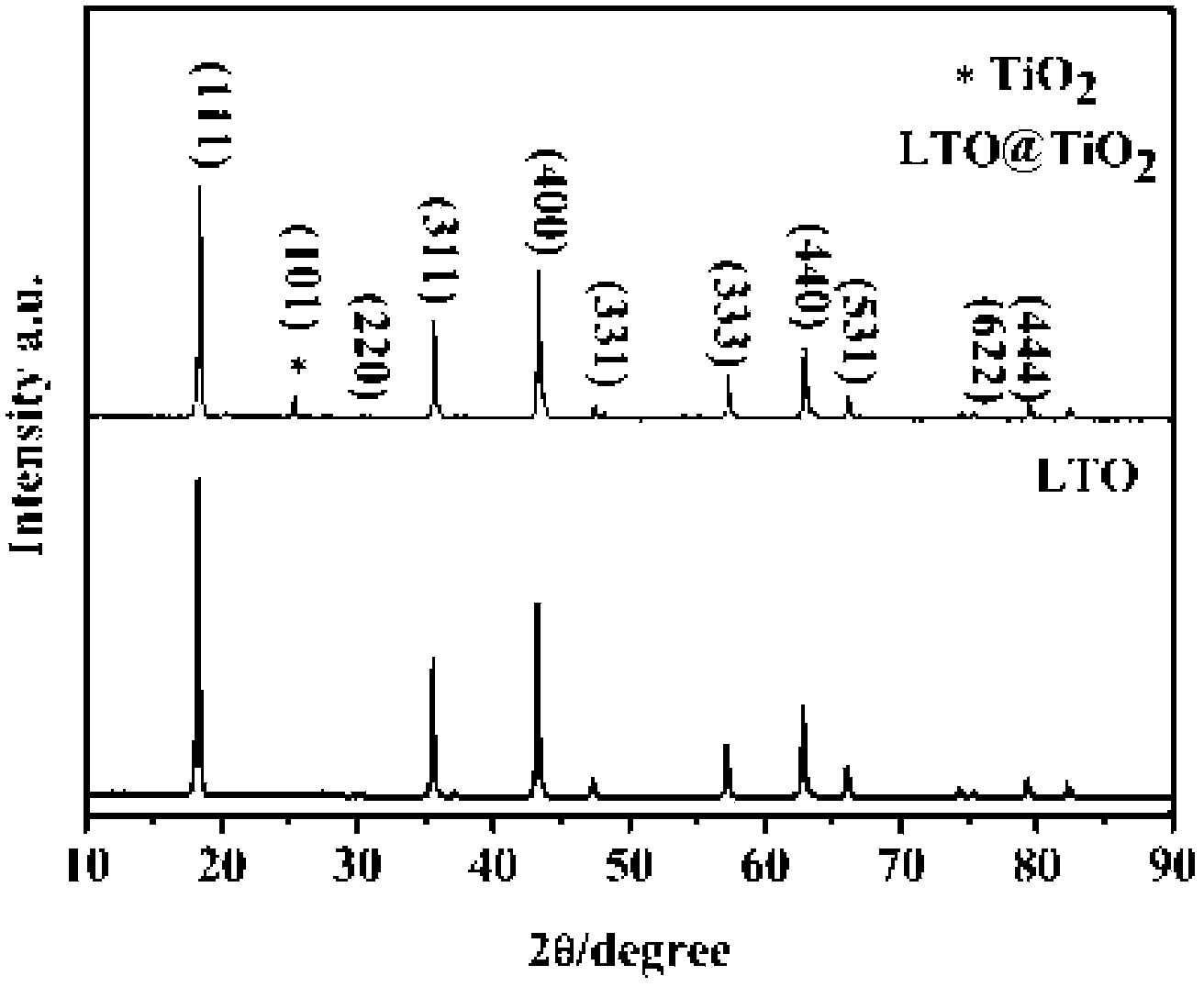

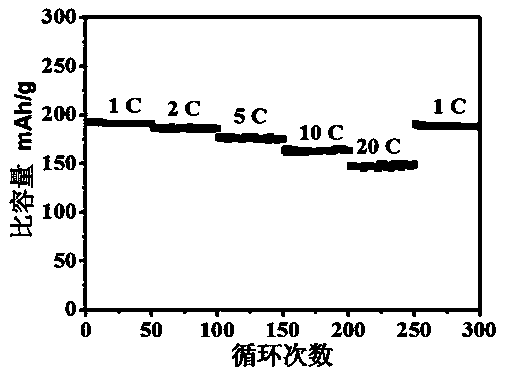

Embodiment 2

[0045] The preparation method of the high specific capacity nano-scale lithium titanate material provided in this example is basically the same as that of Example 1, except that:

[0046] (1) Preparation of liquid A:

[0047]Disperse 34ml of tetra-n-butyl titanate in 60ml of deionized water to obtain liquid A;

[0048] (2) Preparation of liquid B:

[0049] 3.8g lithium hydroxide monohydrate is dispersed in 40ml deionized water, wherein, the ratio of the amount of substance of lithium in the compound of lithium to the amount of substance of titanium in the compound of titanium in step (1) is: n Li :n Ti =1:1.11, you can get liquid B;

[0050] (3) Slowly add liquid B to liquid A, and at the same time, carry out magnetic stirring, and stir for 30 minutes to obtain a mixed solution;

[0051] (4) Put the mixed dispersion obtained in step (3) into a high-temperature reactor, and then place it in an oven at 180°C for 24 hours. After the reaction, cool it down to room temperature ...

Embodiment 3

[0060] The preparation method of the high specific capacity nanoscale lithium titanate material provided in this example is basically the same as that of Examples 1 and 2, except that:

[0061] (1) Preparation of liquid A:

[0062] 10g amorphous TiO 2 Disperse in 50ml deionized water to get liquid A;

[0063] (2) Preparation of liquid B:

[0064] 11.6g lithium acetate is dispersed in 50ml deionized water, wherein, the ratio of the amount of substance of lithium in the compound of lithium and the amount of substance of titanium in the compound of titanium in the step (1) is: n Li :n Ti =1:1.11, you can get liquid B;

[0065] (3) Slowly add liquid B to liquid A, and at the same time carry out magnetic stirring, and stir for 30 minutes to obtain a mixed dispersion;

[0066] (4) Put the mixed dispersion obtained in step (3) into a high-temperature reactor, and then place it in an oven at 140°C for 24 hours. After the reaction, cool it down to room temperature naturally, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com