Single crystal copper growth process

A technology of single crystal copper and process, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low purity of single crystal copper, high preparation cost, complicated operation process, etc., to increase the preparation purity and reduce the difficulty , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

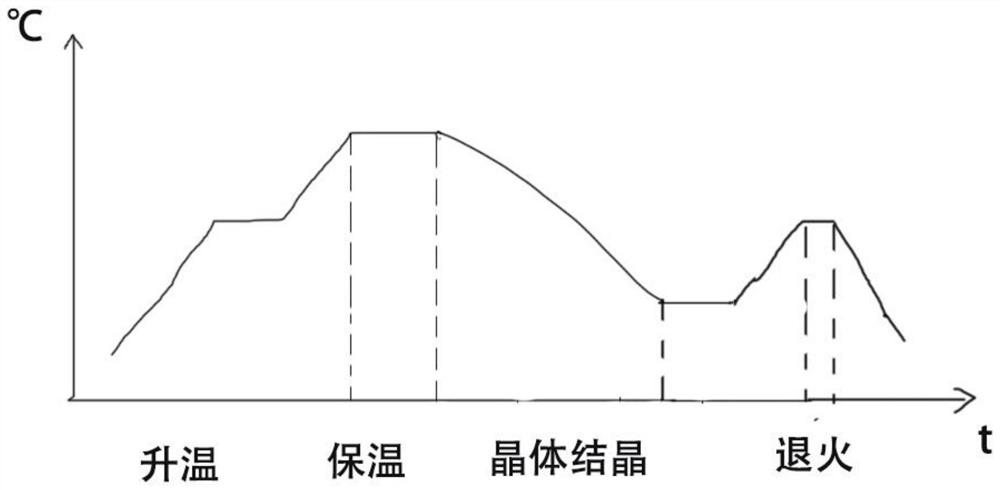

[0021] see figure 1 , the present invention provides a technical solution: a single crystal copper growth process, the specific preparation method steps of the single crystal copper are as follows:

[0022] Heating: Take 4-6 parts of polycrystalline copper, press 4-6 parts of polycrystalline copper through a pressing tool, place the pressed polycrystalline copper inside the crucible, and place the crucible with polycrystalline copper at a high temperature to drop Inside the furnace, continue to heat up the high-temperature drop furnace until the temperature of the high-temperature drop furnace rises to 1150-1350 degrees Celsius, and then vacuumize the inside of the high-temperature drop furnace to 0.001-0.002Pa;

[0023] Heat preservation: when the temperature reaches the range of 1150-1350 degrees Celsius, pour an inert protective gas into the high-temperature descending furnace, and then continue to heat up the high-temperature descending furnace until the temperature is 180...

Embodiment 1

[0033] The concrete preparation method step flow process of this single crystal copper is as follows:

[0034] Heating: Take 4 parts of polycrystalline copper, press the 4 parts of polycrystalline copper through a pressing tool, place the pressed polycrystalline copper inside the crucible, and place the crucible with polycrystalline copper inside the high-temperature drop furnace, Continue to heat up the high-temperature drop furnace until the temperature of the high-temperature drop furnace rises to 1150 degrees Celsius, and then vacuumize the inside of the high-temperature drop furnace to 0.001Pa;

[0035] Insulation: When the temperature reaches 1150 degrees Celsius, pour inert protective gas into the high-temperature descending furnace, and continue to heat up the high-temperature descending furnace until the temperature reaches 1800 degrees Celsius after pouring inert protective gas, keep the temperature unchanged, and continue Keep warm for 1 hour to quickly melt the pol...

Embodiment 2

[0039] The concrete preparation method step flow process of this single crystal copper is as follows:

[0040] Heating: Take 5 parts of polycrystalline copper, press 5 parts of polycrystalline copper through a pressing tool, place the pressed polycrystalline copper inside the crucible, and place the crucible with polycrystalline copper inside the high-temperature drop furnace, Continue to heat up the high-temperature drop furnace until the temperature of the high-temperature drop furnace rises to 1250 degrees Celsius, and then vacuumize the inside of the high-temperature drop furnace until it reaches 0.0015Pa;

[0041] Insulation: When the temperature reaches 1250 degrees Celsius, pour inert protective gas into the high-temperature descending furnace, and continue to heat up the high-temperature descending furnace until the temperature reaches 1850 degrees Celsius, keep the temperature unchanged, and continue Keep warm for 1.5 hours to quickly melt the polycrystalline copper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com