A kind of preparation method of bulk single crystal copper

A single crystal copper, bulk technology, applied in the field of preparation of metal single crystal materials, can solve the problems of complex preparation process and high cost of high-purity single crystal copper, and achieve the effect of easy large-scale promotion, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

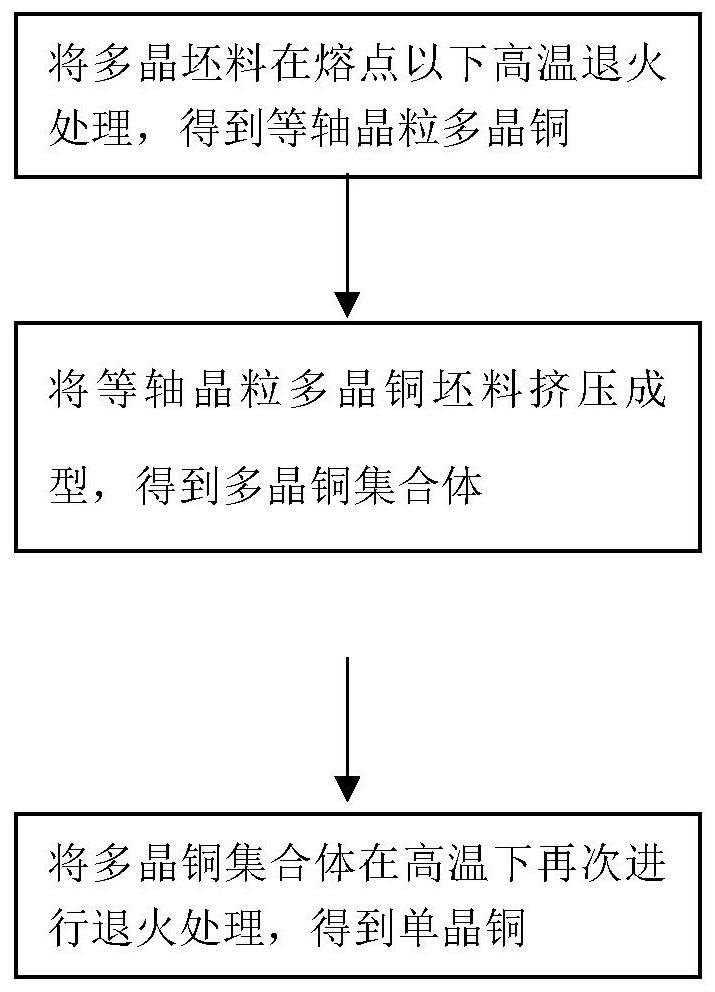

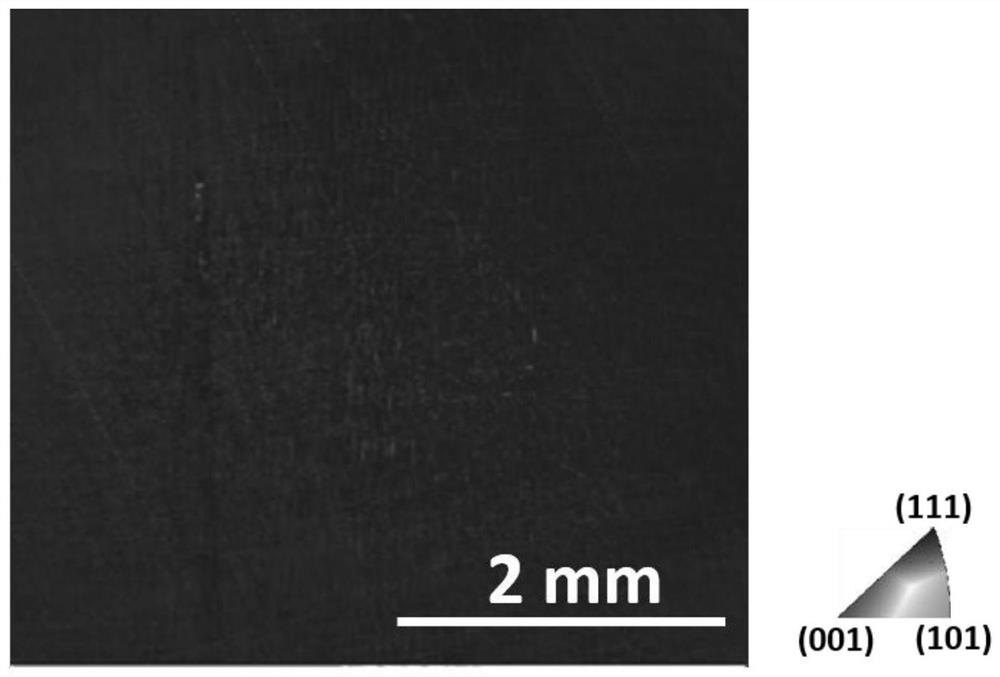

[0026] combine Figure 1 to Figure 4 , to describe this embodiment in detail. A kind of preparation method of bulk single crystal copper involved in the present embodiment, comprises the following steps:

[0027] (1) The polycrystalline copper blank is annealed at a high temperature below the melting point to obtain polycrystalline copper with equiaxed grains; the purity of the used polycrystalline copper blank is 99.9999%.

[0028] In this step, the polycrystalline copper billet after pickling and drying is subjected to high-temperature annealing in a vacuum furnace, and the pressure in the furnace is lower than 1×10 -3 Pa, the temperature is raised to 950-1000°C within 80-90min, and the annealing time is 10 hours.

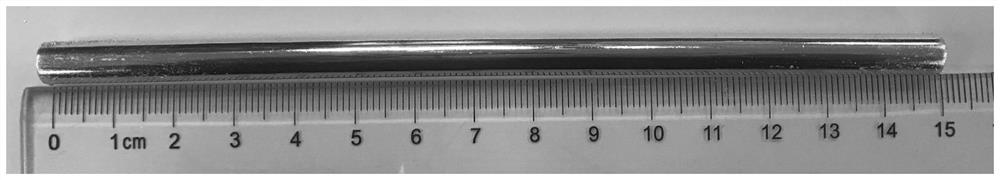

[0029] (2) Extruding the polycrystalline copper blank with equiaxed grains annealed in step (1) to obtain polycrystalline copper aggregates. The cross-section of the polycrystalline copper aggregate can be circular, oval, regular polygon, etc. In this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com