A kind of preparation method of large size single crystal copper foil

A large-size, copper foil technology is applied in the field of preparing large-size single crystal copper foil, which can solve the problems of high price and small size, and achieve the effects of simple method, reduced manufacturing cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

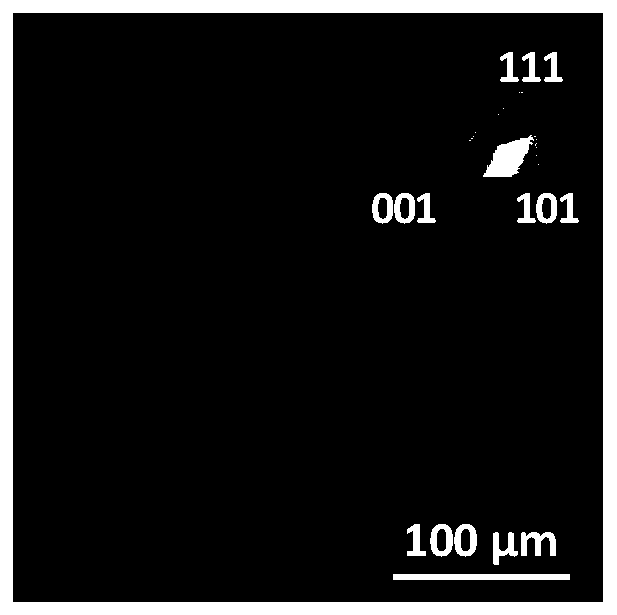

[0018] Embodiment 1: A method for annealing polycrystalline copper to prepare single crystal copper foil, comprising the following steps:

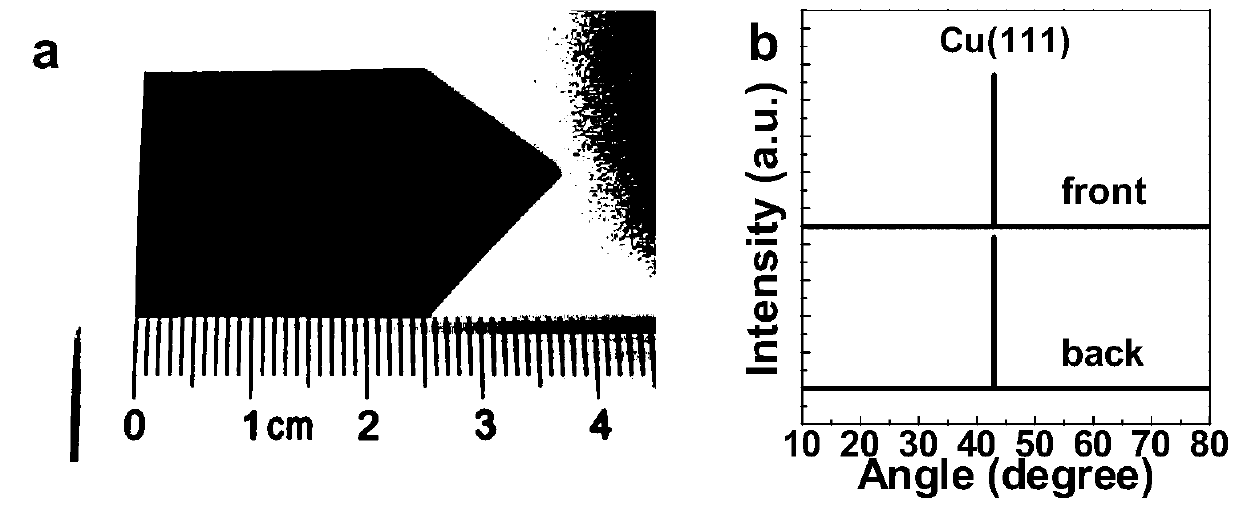

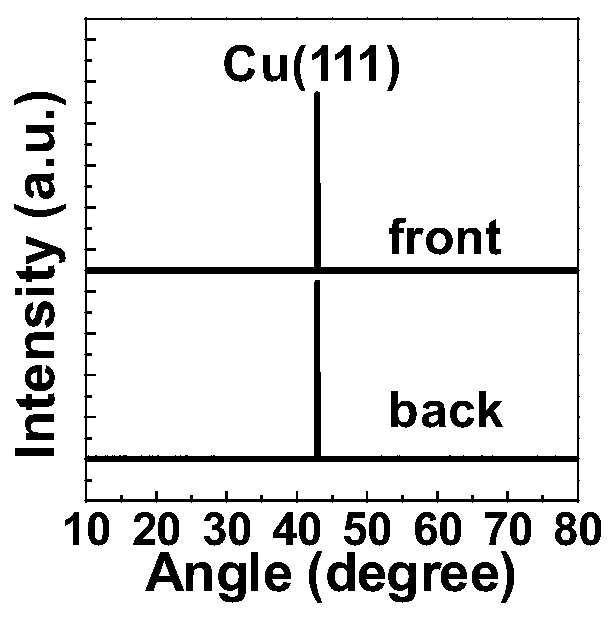

[0019] (1), cut one end of the polycrystalline copper foil into a tip and place it flat on the high-temperature-resistant substrate, connect the transmission device, put it into the chemical vapor deposition equipment, and feed inert gas with a flow rate of 300-500 sccm, and then Start to heat up, the inert gas is N 2 or Ar;

[0020] (2) When the temperature rises to 800-1100°C, the polycrystalline copper foil gradually passes through the chemical vapor deposition equipment from the tip to start the annealing process;

[0021] (3) After the growth is completed, cool down to room temperature to obtain a large-size single crystal copper foil.

[0022] Wherein, the tip is formed by removing any corner of the strip-shaped or rectangular copper foil, or removing two adjacent corners along the width direction of the copper foil at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com