Preparation method of single crystal copper

A single crystal copper and polycrystalline copper technology, applied in the field of materials, can solve the problem of many impurities in single crystal copper, achieve excellent performance, realize industrialized preparation, and improve surface cleanliness and preparation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention provides a method for preparing single crystal copper, which includes the following steps:

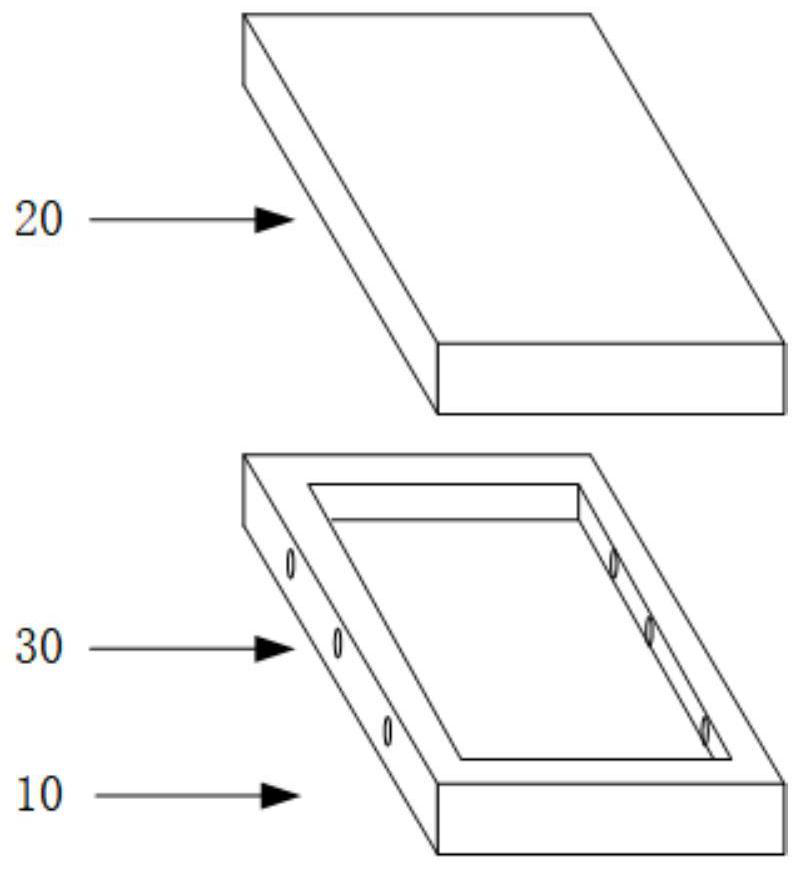

[0032] S1. Provide polycrystalline copper and a container, and the container is provided with at least one through hole;

[0033] S2. The polycrystalline copper is placed in a container and subjected to annealing treatment to obtain single crystal copper.

[0034] In the preparation method of single crystal copper provided in the embodiment of the present invention, polycrystalline copper is placed in a container for annealing treatment, and various impurities such as quartz slag and dust particles in the annealing process are removed by using the confined space of the container. It is isolated from the outside of the container, so as to avoid the above-mentioned impurities from causing impurity pollution to the obtained single crystal copper, which not only greatly improves the surface cleanliness and preparation efficiency of the obtaine...

Embodiment 1

[0049] This embodiment provides a method for preparing single crystal copper foil, the steps are as follows:

[0050] (11) Place the polycrystalline copper foil with a width of 20 cm and a length of 40 cm in the graphite box (the side wall of the graphite box is provided with multiple through holes), put it into the chemical vapor deposition equipment, and feed the protective gas , the protective gas flow rate is 600 sccm, the working pressure is normal pressure, and the protective gas is Ar;

[0051] (12) After the protective gas is introduced, the temperature begins to increase, the heating time is 60min, the temperature is raised to 1000°C, and H 2 Gas, H 2 The flow rate is 100sccm;

[0052] (13) Keep the temperature constant and perform annealing treatment. The annealing time is 30 minutes. After the annealing is completed, an ultra-clean single crystal copper foil is obtained. The width of the single crystal copper foil is 20 cm, the length is 40 cm, and the cleanliness...

Embodiment 2

[0054] This embodiment provides a method for preparing single crystal copper foil, the steps are as follows:

[0055] (21) The polycrystalline copper foil with a width of 20cm and a length of 40cm is placed flat in a graphite box (the graphite box is consistent with Example 1), puts it into a chemical vapor deposition device, and feeds a protective gas. The gas flow rate is 600sccm, the working pressure is normal pressure, and the protective gas is Ar;

[0056] (22) After the protective gas is introduced, the temperature starts to increase, the heating time is 60min, the temperature is raised to 800°C, and H 2 Gas, H 2 The flow rate is 100sccm;

[0057] (23) Keep the temperature constant and perform annealing treatment. The annealing time is 50 minutes. After the annealing is completed, an ultra-clean single crystal copper foil is obtained. The width of the single crystal copper foil is 20 cm, the length is 40 cm, and the cleanliness is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com