Method for reducing roughness of copper foil and copper foil product thereof

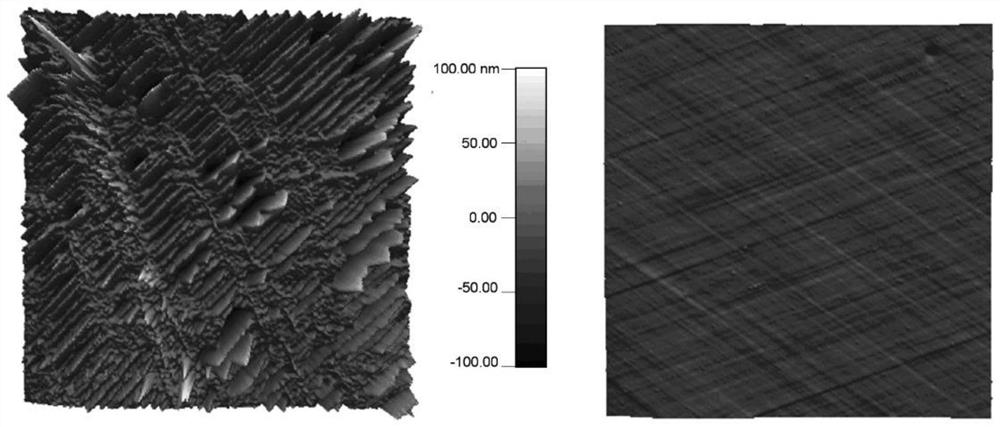

A roughness, copper foil technology, applied in the field of copper foil roughness reduction method and its copper foil products, can solve the problems of low roughness, difficult to control, long polishing time, etc., achieve good mirror effect, less environmental pollution, high polishing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of polishing solution: use 1080ml of 85% concentrated phosphoric acid and 360ml of ethylene glycol of analytical grade, mix and stir at room temperature for 10min to obtain anhydrous phosphoric acid-ethylene glycol polishing solution;

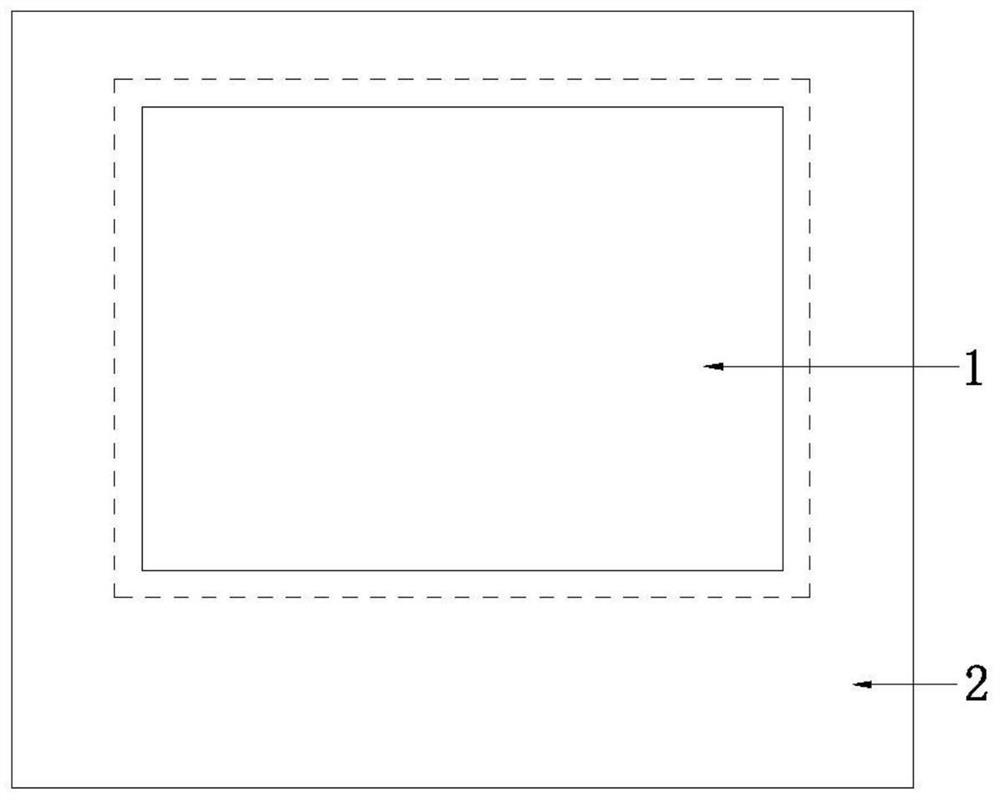

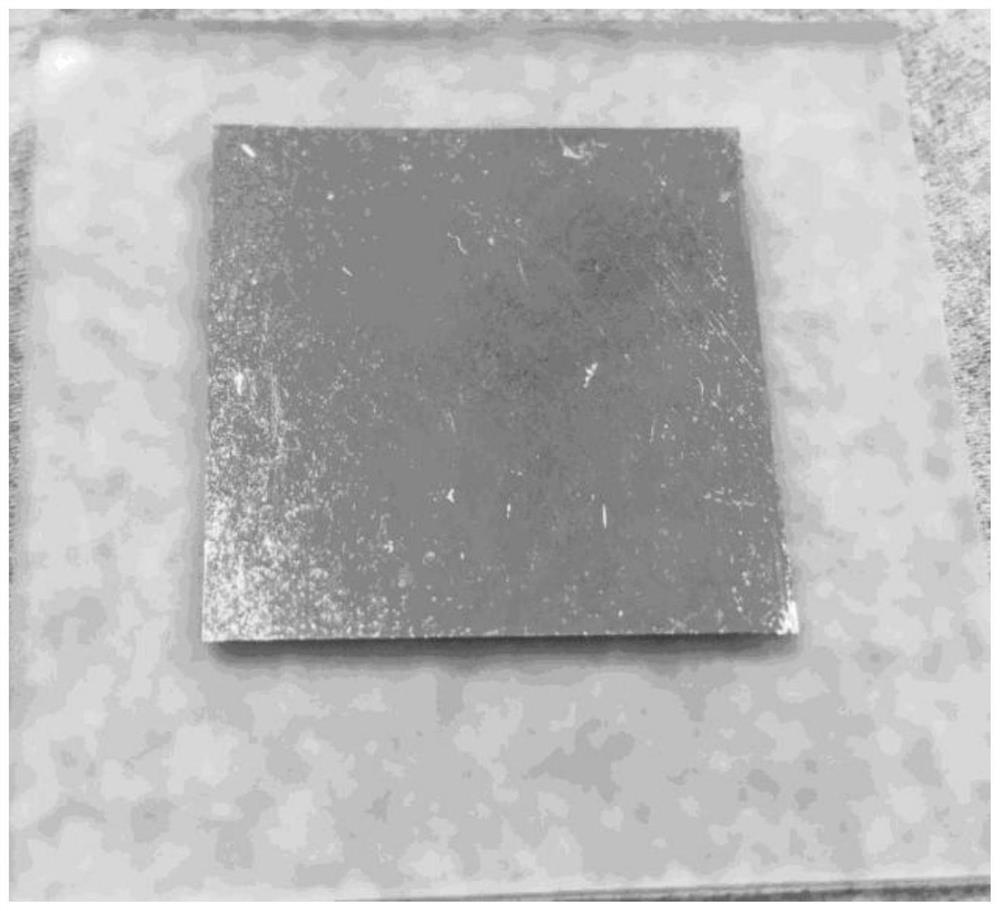

[0032] (2) Treatment of copper foil to be polished: the polycrystalline copper foil is placed in a high-temperature annealing furnace and annealed with hydrogen to obtain a large grain size copper foil with a thickness of 25 μm, which is clamped by a clamp; see figure 1 , using a Universal PLS6.75 laser platform cutting machine to cut an acrylic plate with a thickness of 3mm into two glass plates 2, the glass plate 2 is opened to match the shape of the polycrystalline copper foil 1 to be clamped The opening of the polycrystalline copper foil 1 is placed between two glass plates, and the edge of the opening is pressed against the edge of the polycrystalline copper foil 1 to effectively prevent wrinkles during the polishing...

Embodiment 2

[0036] (1) Preparation of polishing solution: use 720ml of 85% concentrated phosphoric acid and 360ml of ethylene glycol of analytical grade, mix and stir at room temperature for 12min to obtain anhydrous phosphoric acid-ethylene glycol polishing solution;

[0037] (2) Treatment of copper foil to be polished: the polycrystalline copper foil is placed in a high-temperature annealing furnace and annealed with hydrogen to obtain a large grain size copper foil with a thickness of 18 μm, which is clamped by a clamp; see figure 1 , using a wire electric discharge machine or a cutting machine to cut stainless steel with a thickness of 2mm into two metal plates, the metal plate has an opening that matches the outline of the polycrystalline copper foil to be clamped, and the The polycrystalline copper foil is placed between two metal plates, and pressed against the edge of the polycrystalline copper foil through the edge of the opening;

[0038] (3) Electrochemical polishing: Electroche...

Embodiment 3

[0041] (1) Preparation of polishing liquid: use 1080 ml of 85% concentrated phosphoric acid and 360 ml of ethylene glycol of analytical grade, mix and stir at room temperature for 25 minutes to obtain anhydrous phosphoric acid-ethylene glycol polishing liquid;

[0042] (2) Treatment of copper foil to be polished: the polycrystalline copper foil is placed in a high-temperature annealing furnace and annealed with hydrogen to obtain a large grain size copper foil with a thickness of 36 μm, which is clamped by a clamp; see figure 1 , using a laser cutting machine to cut the aluminum alloy with a thickness of 1.5mm into two metal plates, the metal plate has an opening that matches the outline of the polycrystalline copper foil to be clamped, and the polycrystalline copper The foil is placed between two metal plates and pressed against the edge of the polycrystalline copper foil through the edge of the opening;

[0043] (3) Electrochemical polishing: Electrochemically polish copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com