Directional heat conduction pcb board and electronic equipment

A PCB board, directional heat conduction technology, applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of upward heat conduction, uneven heat conduction, large thermal resistance coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Please refer to figure 1 , is a schematic diagram of the electronic device of the present invention. The electronic device includes a certain heat conduction PCB board 10 arranged in its casing. The directional heat conduction PCB board 10 is used to replace the traditional PCB board to carry several electronic components, such as resistors, capacitors, integrated circuits (ICs) and so on. In this embodiment, the electronic equipment includes, but is not limited to, electronic devices such as various consumer electronic equipment, network servers, radio frequency equipment, and electronic communication equipment.

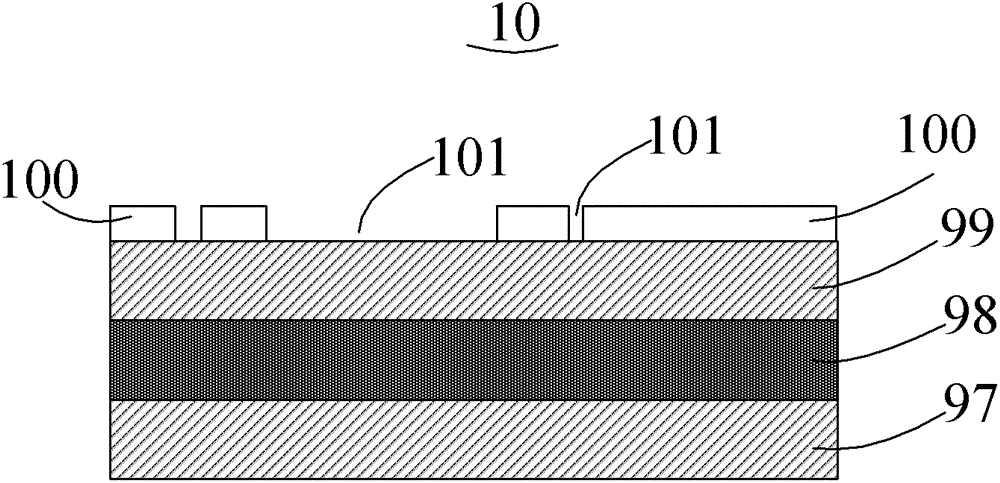

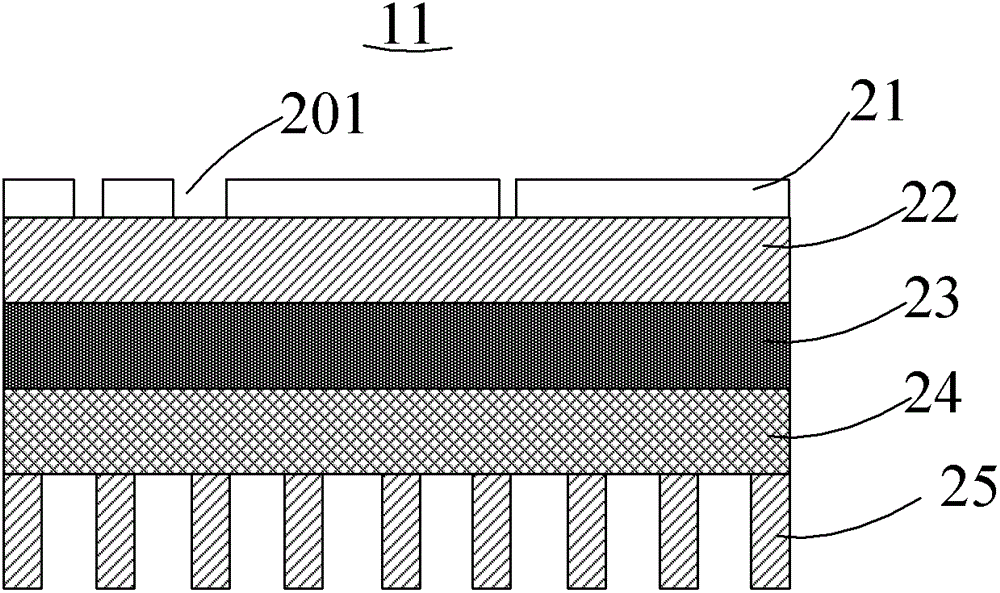

[0019] Please refer to figure 2 , the directional heat conduction PCB board 10 includes a first metal layer 97 , a heat conduction medium layer 98 , a second metal layer 99 and a copper clad layer 100 . The copper clad layer 100 and the heat conduction medium layer 98 are respectively disposed on two sides of the second metal layer 99 , and the first meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com