Continuous production system of azo reactive dye using supergravity

A reactive dye and supergravity technology, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of large volume, low dye production efficiency, inconvenient application of post-treatment dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

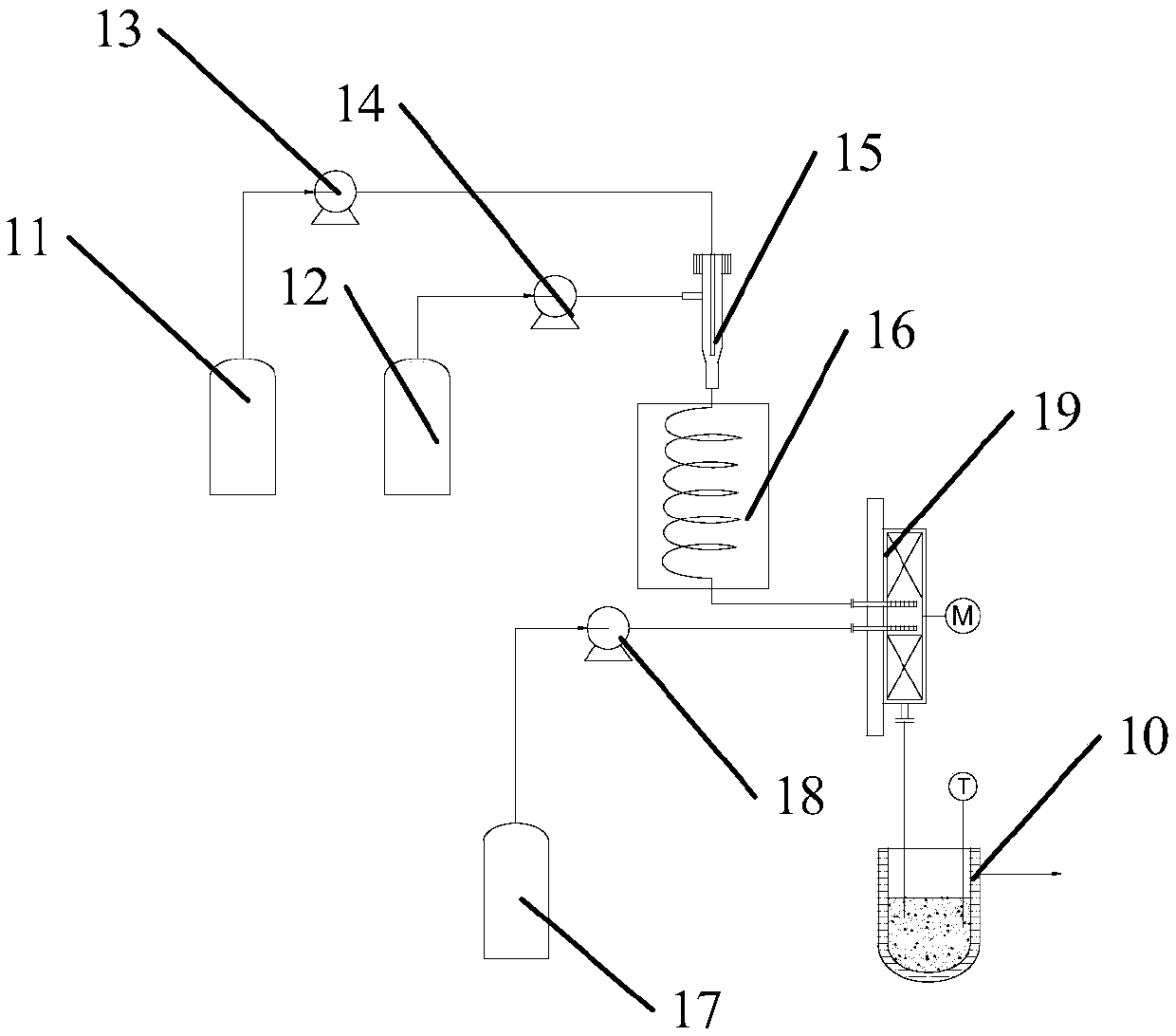

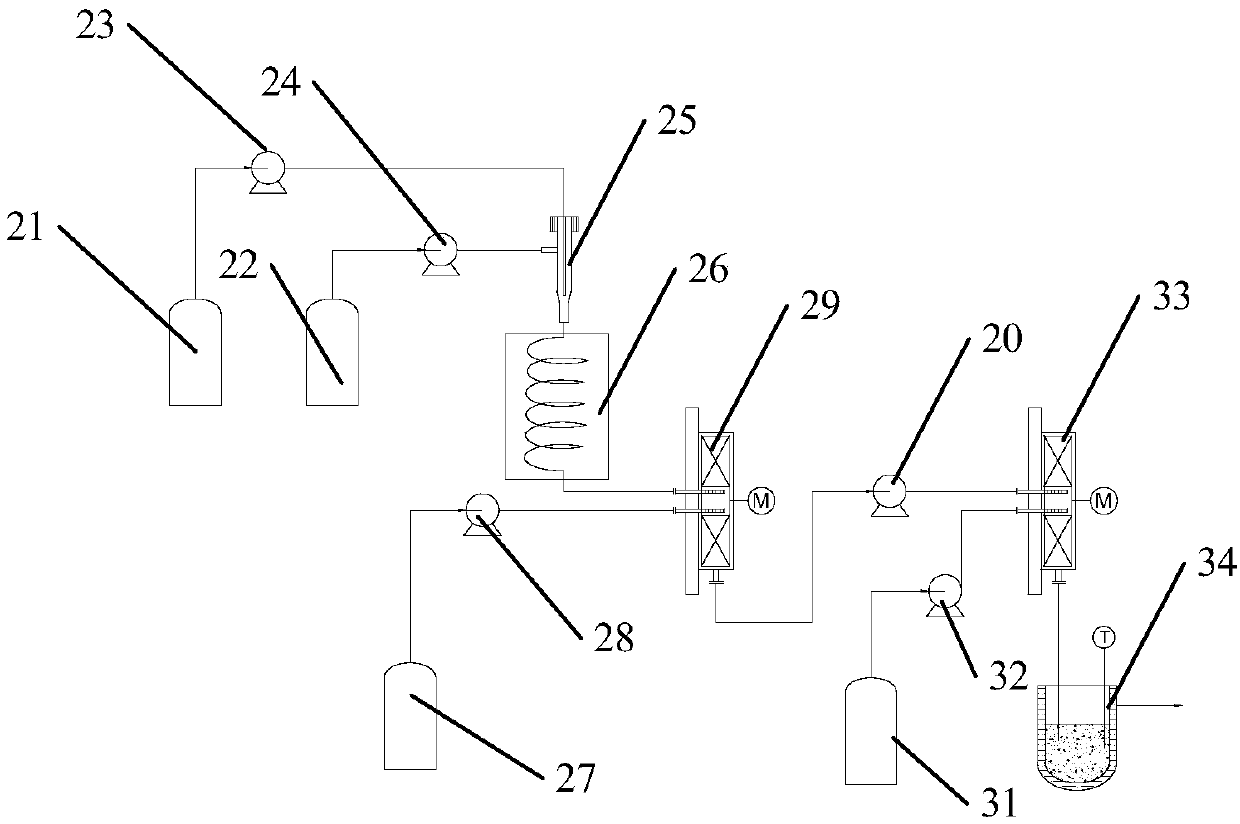

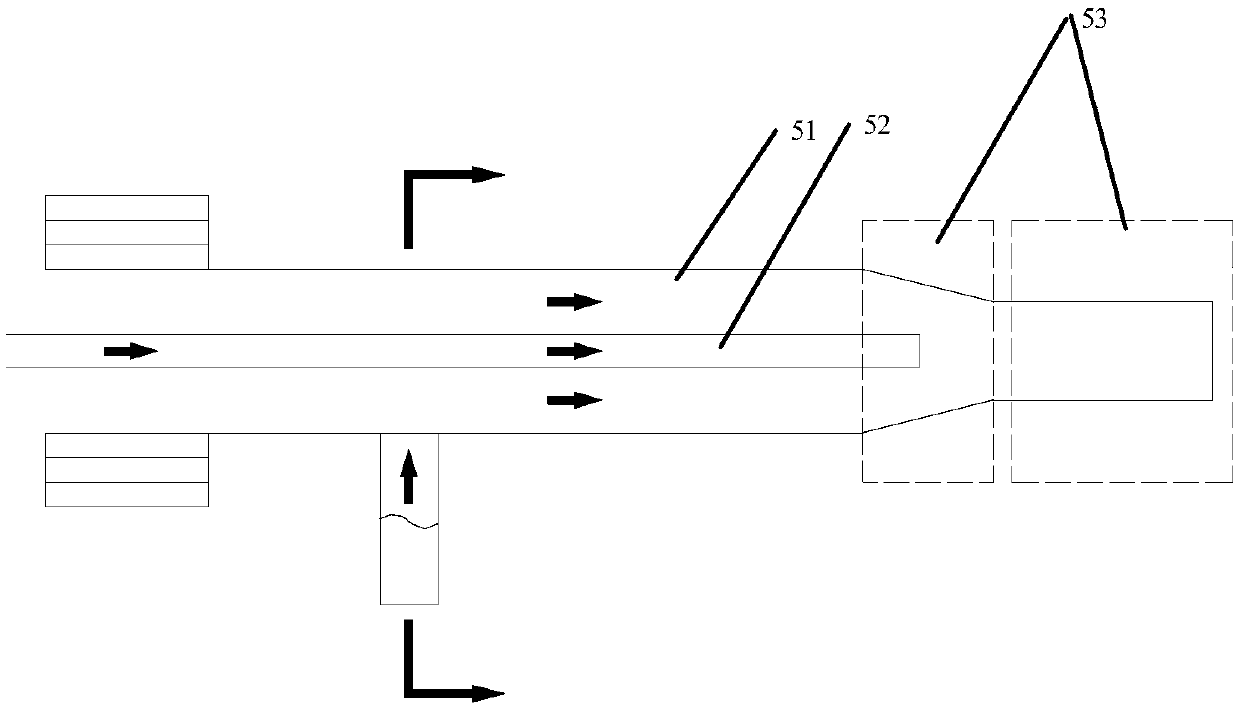

[0038] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0039] In industry, reactive azo dyes are carried out in batch operation in stirred tank reactors. Due to the complexity of the organic reaction and the large size of the stirred tank reactor, the temperature and mixing effect of the materials are difficult to achieve uniformity in local areas, the conversion rate and production efficiency of the dye are low, and the dyes produced by the batch stirred tank vary between batches. The difference is large, which brings inconvenience to the post-processing of the dye and the ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com