Easy-to-repair thermal-conducting gel and preparation method thereof

A gel and repair technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of large amount of residual glue of thermal conductive gel, difficult to repair and other problems, achieve excellent thermal conductivity, improve storage temperature, and excellent processing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

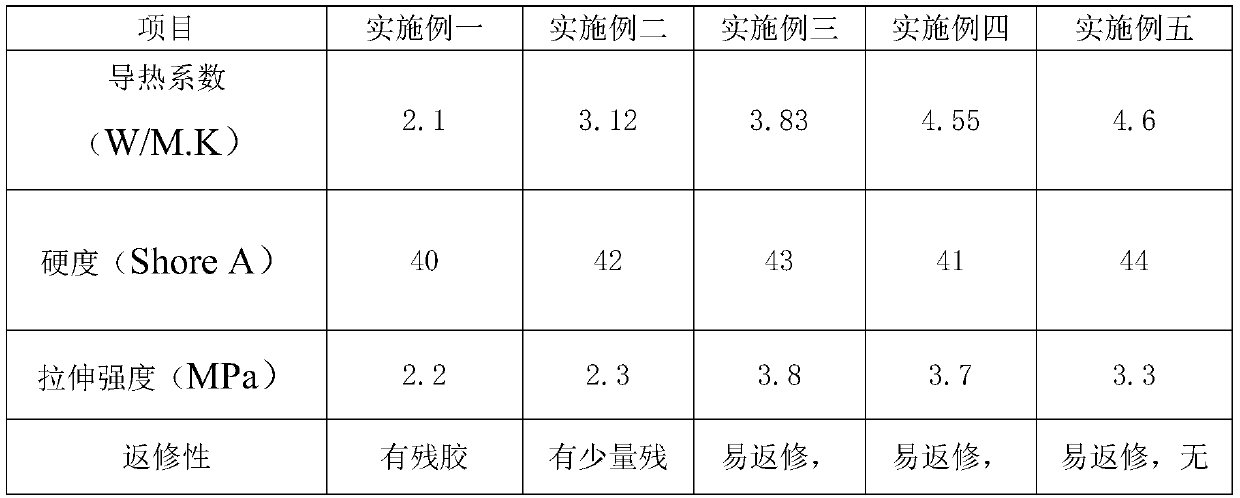

Examples

Embodiment 1

[0027] Take by weighing 5g of vinyl silicone oil with a viscosity of 500mPa.s, 3g of vinyl MQ resin with a viscosity of 1000mPA.s, 0.5g of hydrophobic white carbon black, and 0.1g of hexadecyltrimethoxysilane, join in the kneader, and Heat the material to 150°C, evacuate until the vacuum degree reaches -0.1MPa, and keep stirring for 180min. After the stirring is completed, cool the mixture to room temperature, add 0.5 g of hydrogen-terminated silicone oil with a hydrogen content of 0.18%, 0.04 g of acetylene cyclohexanol, 15 g of alumina with a particle size of 5 μm, 16 g of alumina with a particle size of 20 μm, and aluminum oxide with a particle size of 40 μm. Aluminum 24g, continue to stir for 30min. Finally, 2000ppm of chloroplatinic acid (based on the mass of platinum) was added, stirred for 30 minutes, and the obtained paste was the finished heat-conducting gel.

Embodiment 2

[0029] Weigh 5g of ethyl silicone oil with a viscosity of 200mPa.s, 3g of vinyl MQ resin of 600mPA.s, 0.5g of hydrophobic white carbon black, and 0.2g of hexadecyltrimethoxysilane, add them to the kneader, and heat the material To 150 degrees, vacuum until the vacuum degree reaches -0.1MPa, and keep stirring for 180min. After the stirring is completed, cool the mixture to room temperature, add 0.7 g of hydrogen-terminated silicone oil with 0.18% hydrogen content, 0.5 g of long-chain alkyl modified silicone oil, 0.04 g of acetylene cyclohexanol, and 15 g of aluminum nitride with a particle size of 5 μm. 16g of 20μm alumina, 20g of 40μm alumina, and continue to stir for 30min. Finally, 2000 ppm of microcapsule-type platinum catalyst (based on the mass of platinum) was added and stirred for 30 minutes, and the obtained paste was the finished heat-conducting gel.

Embodiment 3

[0031] Weigh 5g of ethyl silicone oil with a viscosity of 100mPa.s, 3g of vinyl MQ resin of 500mPA.s, 0.8g of hydrophobic white carbon black, and 0.15g of hexadecyltrimethoxysilane, add them to the kneader, and heat the material To 150 degrees, vacuum until the vacuum degree reaches -0.1MPa, and keep stirring for 180min. After the stirring was completed, the mixture was cooled to room temperature, 2 g of side-chain hydrogen-containing silicone oil with 0.18% hydrogen content, 0.6 g of long-chain aralkyl modified silicone oil, 0.03 g of acetylene cyclohexanol, and 15 g of aluminum nitride with a particle size of 5 μm were added. 20 g of aluminum nitride with a particle size of 20 μm, 10 g of aluminum oxide with a particle size of 20 μm, and 40 g of aluminum oxide with a particle size of 40 μm, and continue to stir for 30 minutes. Finally, 2000 ppm of microcapsule-type platinum catalyst (based on the mass of platinum) was added and stirred for 30 minutes, and the obtained paste ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com