A kind of processing method of high-quality frozen lotus root slices

A processing method, the technology of freezing lotus, which is applied in the direction of freezing/refrigerating preservation of fruits/vegetables, food preservation, climate change adaptation, etc., and can solve the problems that fruits and vegetables are prone to frost cracking and damage, lack of pertinence, and ice crystal growth, etc. problems, to achieve the effect of retention of sensory and nutritional indicators, good fresh-keeping quality, and small damage to the tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

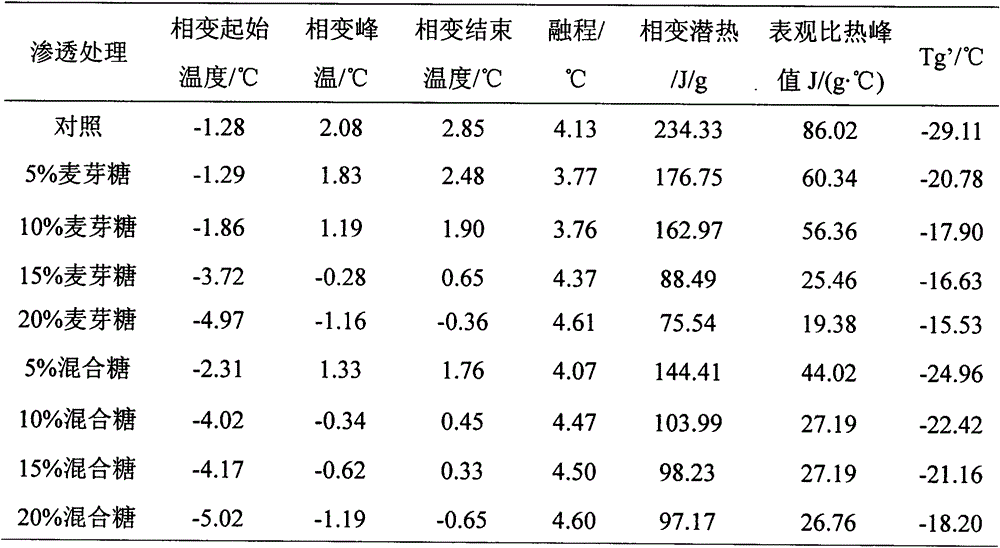

[0025] Choose fresh, white, crisp and undamaged lotus roots, wash them, peel them, and cut them into slices with a thickness of 4mm. Then use a mixed solution of citric acid, Vc, and sodium hexametaphosphate to protect the color for 30 minutes. The mass concentrations of the components are 0.4% citric acid, 2.0% Vc, and 0.2% sodium hexametaphosphate; the color-protected raw materials are added to a solution containing 0.1% citric acid by mass, and microwave blanching is performed for 60 seconds. 2450MHz, microwave power of 500W; the lotus root slices after blanching are placed under a vacuum condition of 0.08~0.1MPa, and permeated in a maltose conditioning solution with a mass concentration of 20% at 25°C for 30 minutes. Among them, the lotus root slices The weight ratio to the conditioning liquid is 1:2; the lotus root slices after vacuum sugar infiltration are quickly frozen at -35°C, until the center temperature of the lotus root slices reaches -18°C or less. Refrigerate the...

Embodiment 2

[0027] Choose fresh, white, crisp and undamaged lotus roots, wash them, peel them, and cut them into slices with a thickness of 5mm. Then use a mixed solution of citric acid, Vc, and sodium hexametaphosphate to protect the color for 30 minutes. The mass concentrations of the components are 0.4% citric acid, 2.0% Vc, and 0.2% sodium hexametaphosphate; the raw materials after color protection are added to a solution containing 0.1% citric acid by mass, and microwave blanching is performed for 40 seconds. The blanched lotus root slices are placed in a vacuum condition of 0.08~0.1MPa under a vacuum condition of 0.08~0.1MPa, and are permeated for 40 minutes in a maltose conditioning solution with a mass concentration of 10% at 25°C. The microwave power is 450W. The weight ratio to the conditioning solution is 1:1.5; the lotus root slices after vacuum sugar infiltration are quickly frozen at -30°C, until the center temperature of the lotus root slices reaches below -18°C. Refrigerate...

Embodiment 3

[0029] Choose fresh, white, crisp and undamaged lotus roots, wash them, peel them, and cut them into slices with a thickness of 6mm. Then use a mixed solution of citric acid, Vc, and sodium hexametaphosphate to protect the color for 30 minutes. The mass concentrations of the components are respectively 0.4% citric acid, 2.0% Vc, and 0.2% sodium hexametaphosphate; the raw materials after color protection are added to a solution containing 0.1% citric acid by mass, and microwave blanching is performed for 80 seconds. 2450MHz, microwave power of 500W; the lotus root slices after blanching are placed in a vacuum condition of 0.08~0.1MPa, in a maltose conditioning solution with a mass concentration of 20% at 25°C for 30 minutes. Among them, the lotus root slices The weight ratio to the conditioning liquid is 1:2; the lotus root slices after vacuum sugar infiltration are quickly frozen at -40°C, until the center temperature of the lotus root slices reaches below -18°C. Refrigerate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com