Packaging-free UVLED solidification light source module

A light source module and LED chip technology, which is applied in the direction of electric solid-state devices, electrical components, circuits, etc., can solve the problems of limited radiant energy of a single LED, energy density that cannot meet the needs of curing, and high-integration assembly that cannot be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings.

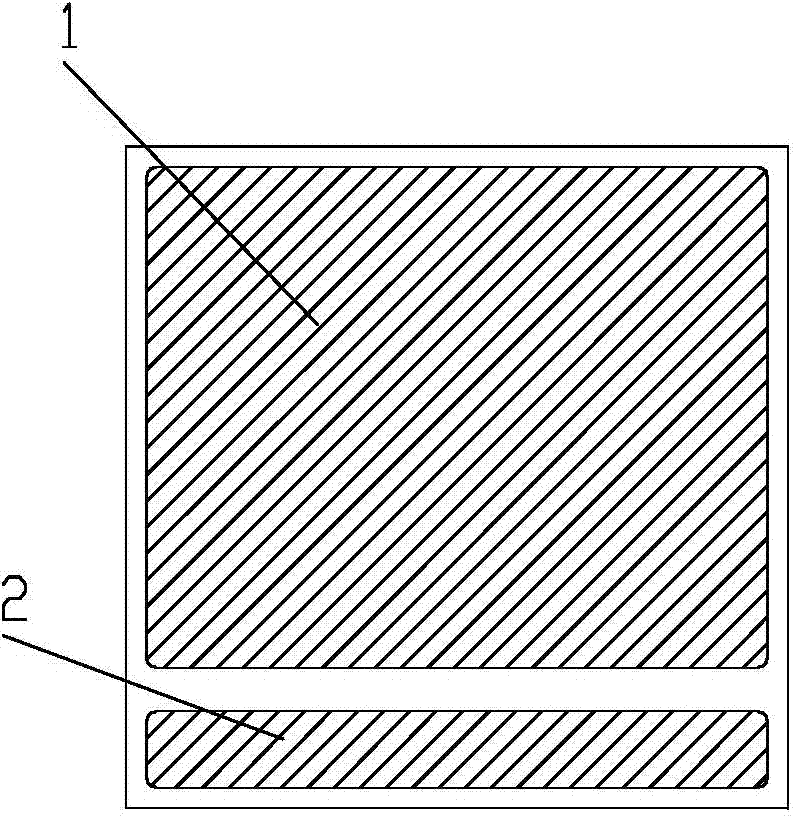

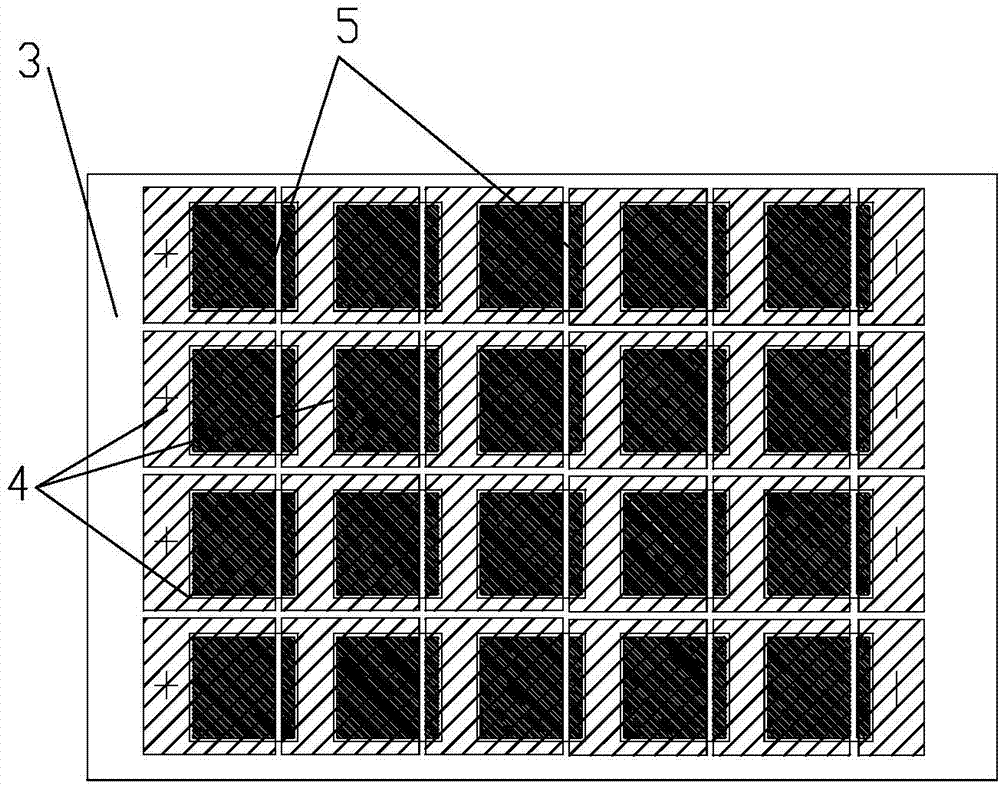

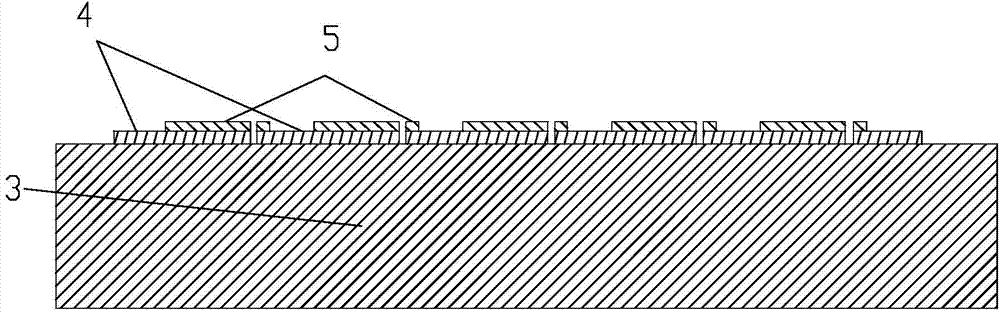

[0013] Such as Figure 1 ~ Figure 4 As shown: the package-free UVLED curing light source module includes P eutectic electrode 1, N eutectic electrode 2, silicon substrate 3, reflective interconnection layer 4, positive and negative eutectic layer 5, LED chip 6, potting glue 7, Water cooling radiator 8, water inlet pipe 9, water outlet pipe 10, welding layer 11, etc.

[0014] Such as Figure 4 As shown, the package-free UVLED curing light source module of the present invention includes a silicon substrate 3, a reflective interconnection layer 4 is provided on the front surface of the silicon substrate 3, and several groups of positive and negative eutectic layers 5 are provided on the upper surface of the reflective interconnection layer 4, each Both the positive and negative eutectic layers 5 are composed of a P eutectic electrode 1 and an N eutectic electrode 2. An LED chip 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com