Corrosion measurement field device

A measurement equipment and equipment technology, applied in the direction of measurement device, measurement of electrical variables, measurement of resistance/reactance/impedance, etc., can solve problems such as inability to provide corrosion measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

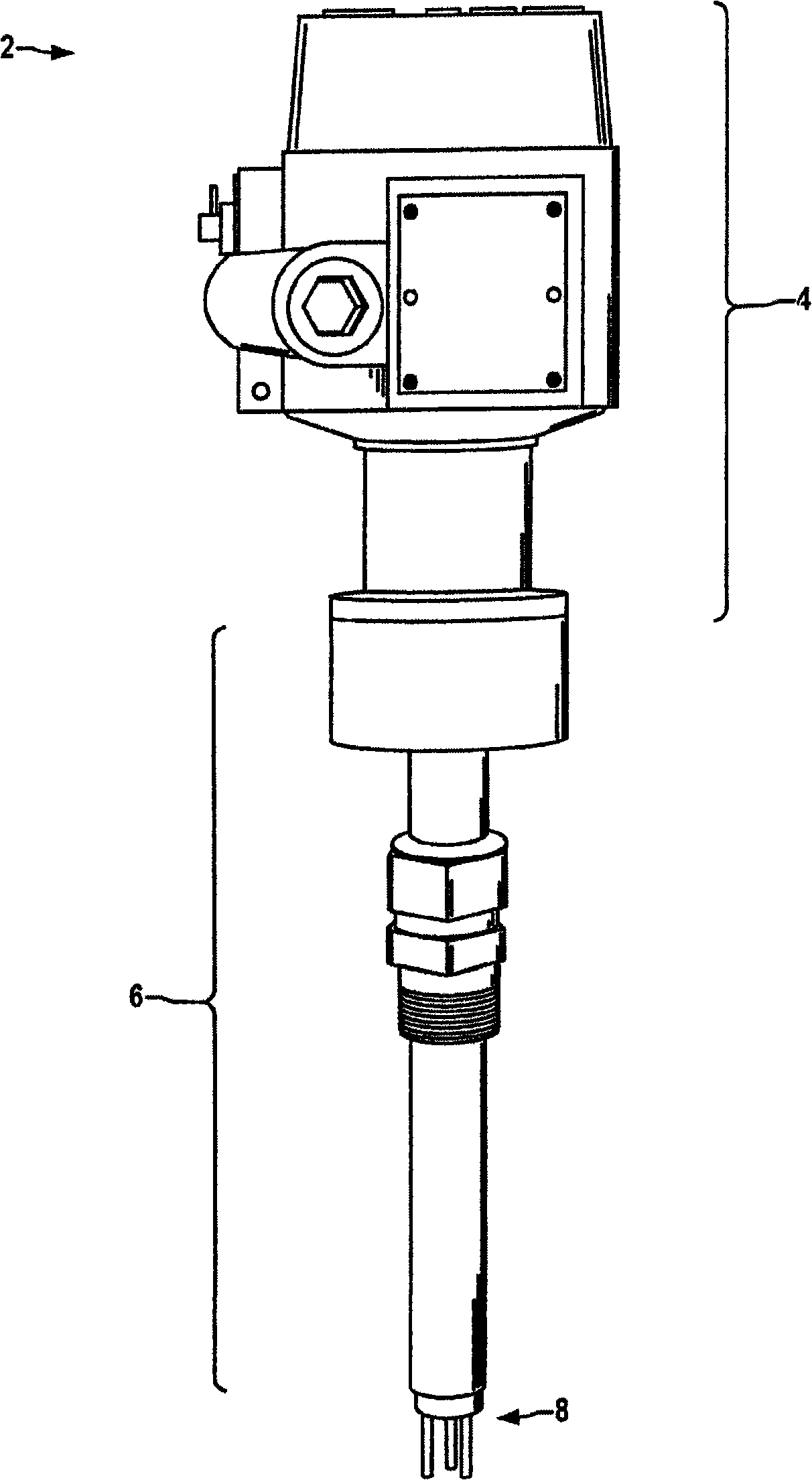

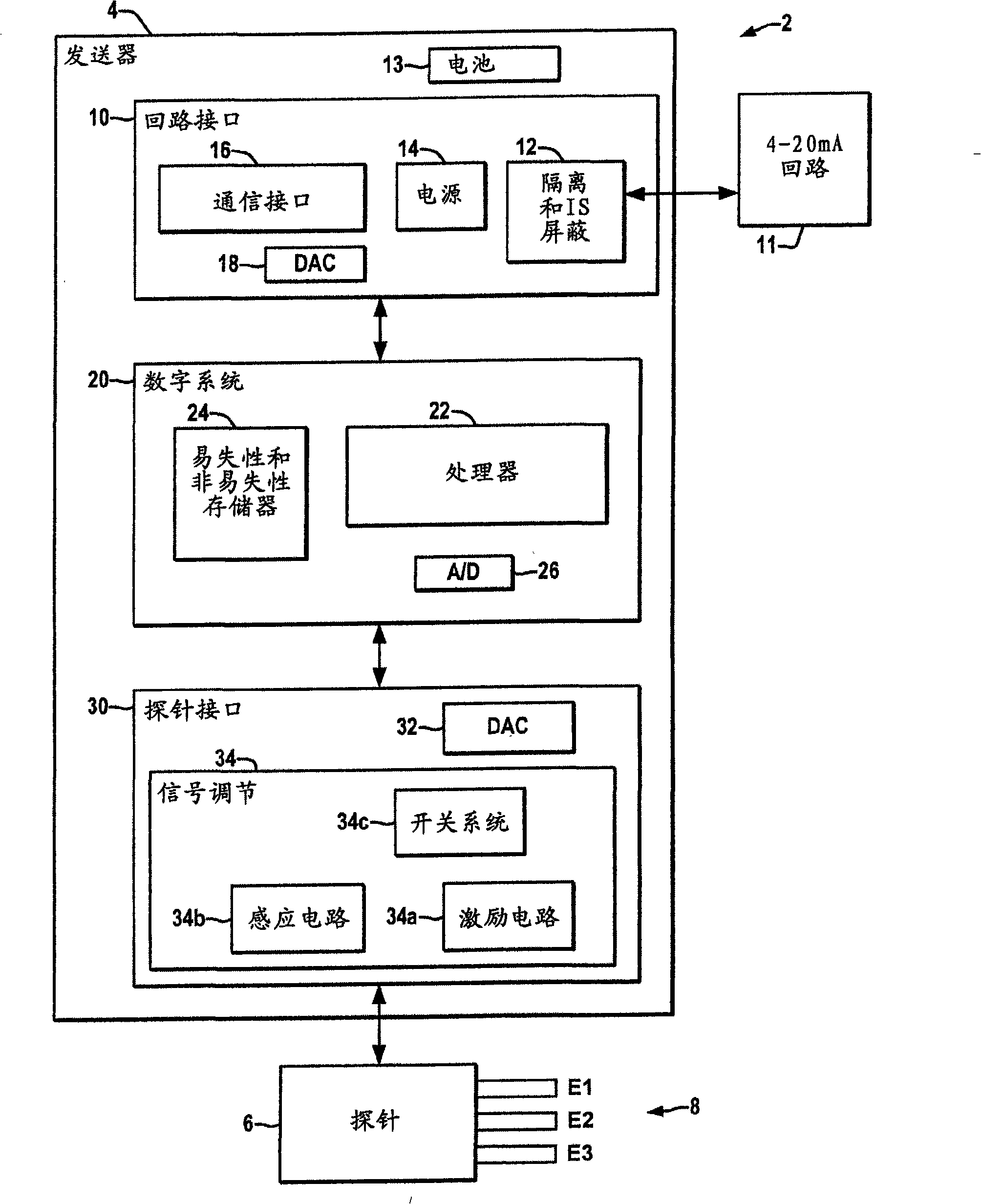

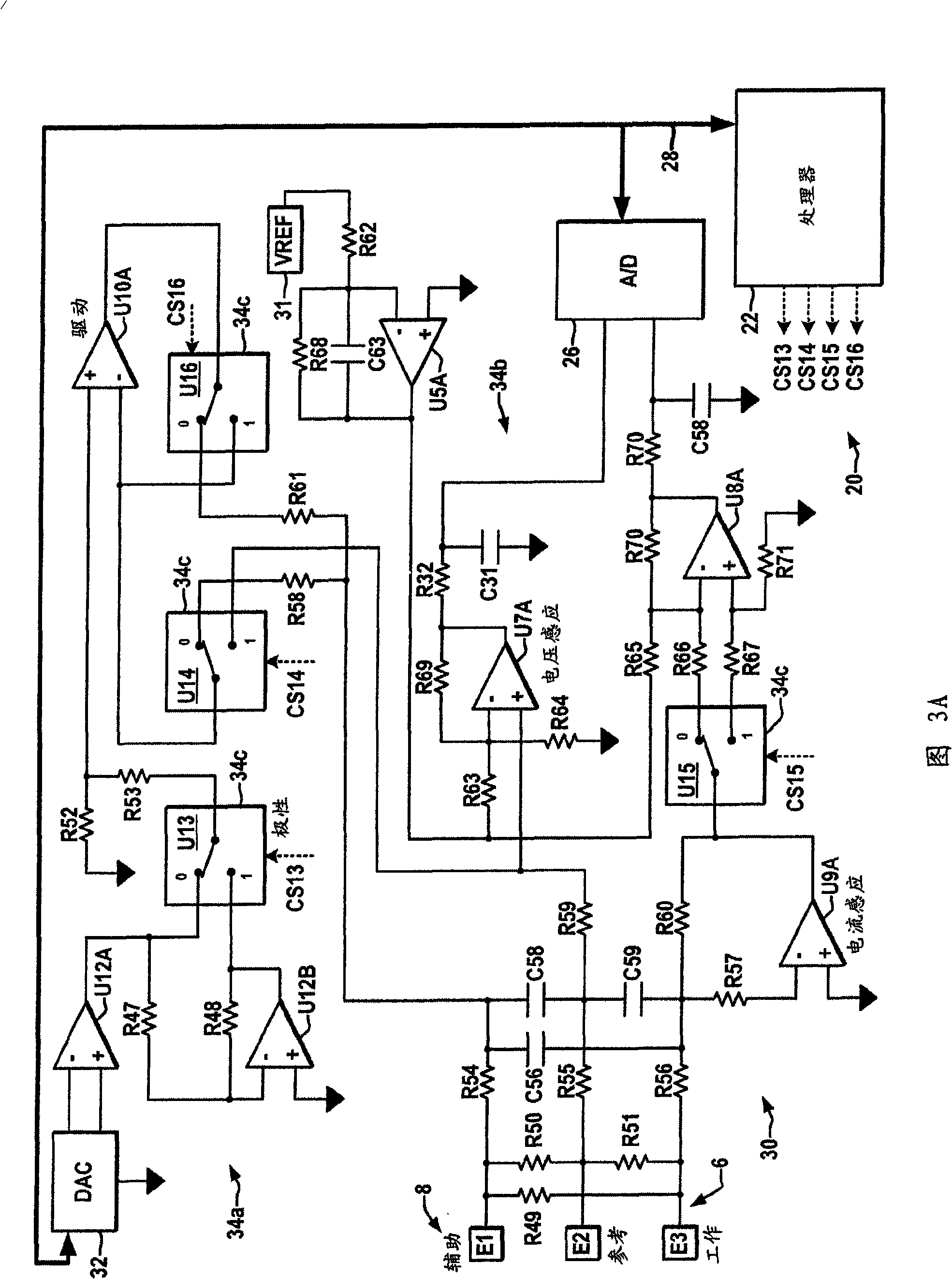

[0036] Referring now to the drawings, several embodiments or implementations of the present invention are described below in conjunction with the drawings, in which like reference numerals are used for like elements throughout the specification and in which various features and curves are not drawn to scale. The present invention relates to a programmable low-power corrosion measurement field device, which uses one or more advanced corrosion measurement methods to provide corrosion measurement and monitoring, providing conductance values, conventional corrosion values, and / or localized corrosion values, etc., thereby real-time Perform corrosion monitoring and / or offline corrosion data archiving (log), and the archived data can be used in a distributed control system connected through a standard 4-20mA control loop or other communication device, or as a stored Corrosion data to the stand-alone device of the user communication device to operate.

[0037] first reference figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com