Device and method for evaluating inhibitor film integrity under scouring work conditions

A corrosion inhibitor film and integrity technology, which is applied in the field of devices for evaluating the integrity of corrosion inhibition films, can solve the problem of lack of fluid wall shear force measurement devices in corrosion evaluation devices, surface corrosion process of difficult-to-test pieces, and lack of on-line corrosion monitoring means And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A detailed description will be made in conjunction with the drawings and specific embodiments of the present invention.

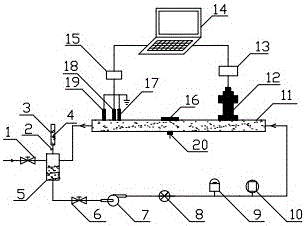

[0045] A device for evaluating the integrity of a corrosion inhibitor film under scour conditions, such as figure 1As shown, it includes a flow supply circulation unit, a shear force measurement unit, an electrochemical monitoring unit, a camera observation unit, a test piece test unit and a corrosion inhibitor filling unit;

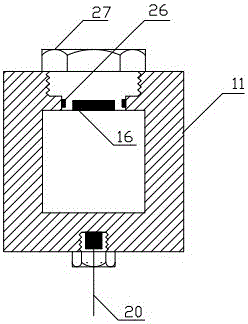

[0046] The flow supply circulation unit is composed of a one-way valve (1), a heating reactor (5), a main control valve (6), an anti-corrosion centrifugal pump (7), a flow control valve (8), a pressure regulator (9), An electromagnetic flowmeter (10) and a transparent plexiglass tube (11) are formed;

[0047] Described shear force measurement unit is made of shear force sensor (12), controller (13) and computer (14);

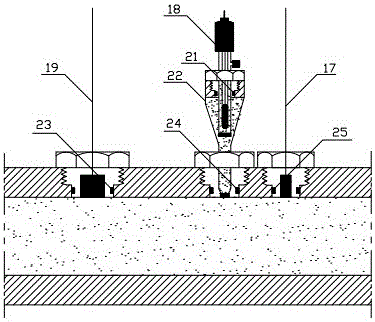

[0048] Described electrochemical monitoring unit is made of working electrode (17), reference electrode (18)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com