Oil and gas pipeline corrosion online monitor

A technology for oil and gas pipelines and corrosion monitoring, applied in the direction of material resistance, etc., can solve the problems of not pointing out the temperature, having a great influence on temperature measurement, and not using it, so as to achieve the effect of improving the accuracy of corrosion measurement, improving the measurement accuracy, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

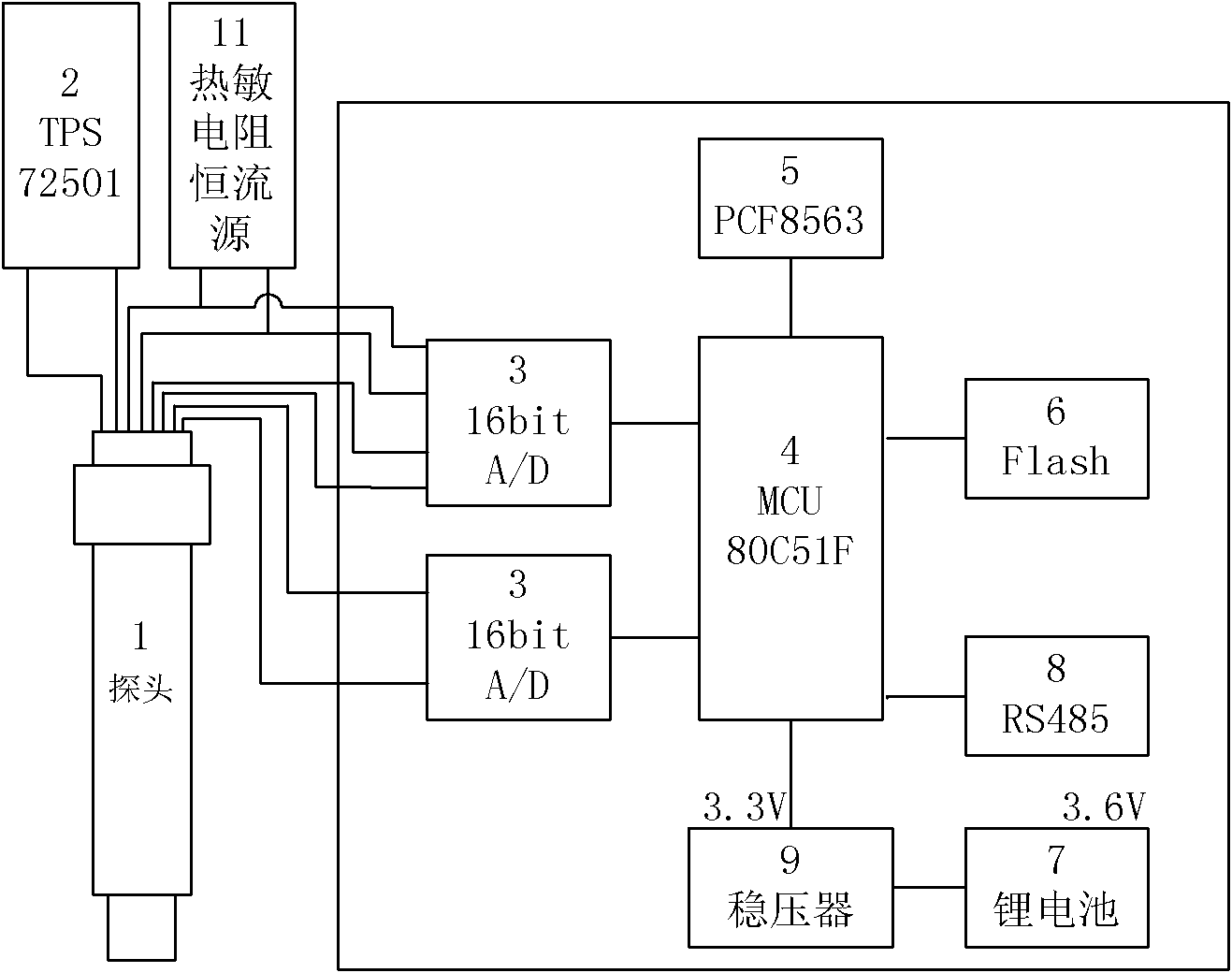

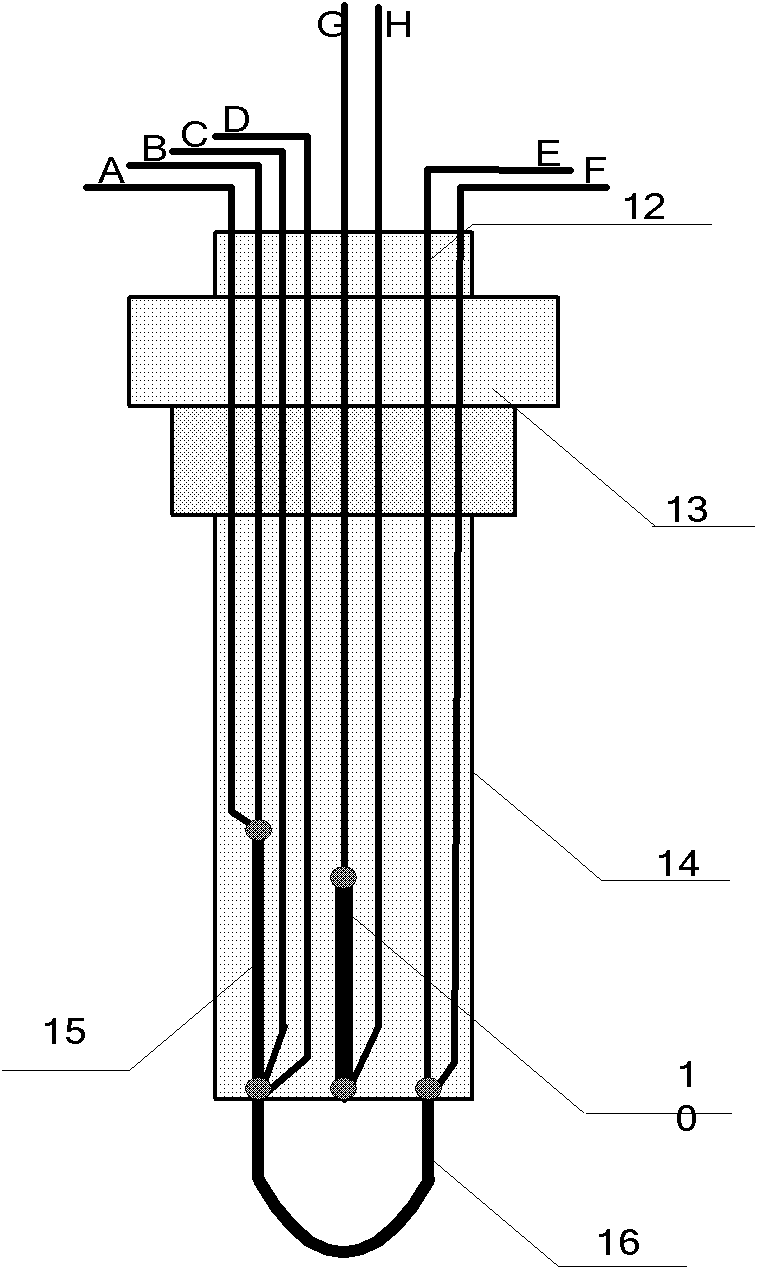

[0031] see figure 1 , the high-precision resistance method online corrosion monitor of the present invention includes: 1-resistance probe; 2-alternating constant current source; 3-dual-channel A / D converter; 4-single-chip microcomputer; 7-lithium battery; 8-communication interface; 9-power regulator; 11-DC constant current source.

[0032] There is a single-chip microcomputer 4 in the IP65 protection grade housing, and the single-chip microcomputer 4 adopts a high-speed and low-power consumption 80C51F type MCU. The single-chip microcomputer 4 is respectively connected with the real-time clock 5 , the data memory 6 , the communication interface 8 and the power regulator 9 , and the power regulator 9 is connected with the lithium battery 7 . Real-time clock 5 adopts PCF8563 clock chip; data memory 6 adopts Flash memory or ferroelectric memory; communication interface 8 adopts isolated RS485 interface; thermistor 10 adopts PT100 or semiconductor thermistor; DC constant current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com