Corrosion monitoring device and method for reinforcement bar in concrete structure

A technology for corrosion of concrete structures and steel bars, which is applied in the direction of material inspection products, etc., can solve the problems of increased monitoring difficulty, inconvenient placement of sensors, and differences in steel corrosion monitoring results, and achieves high test results accuracy, flexible structural form, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1 A method for monitoring the corrosion of steel bars in a concrete structure:

[0045] (1) Design and production of test pieces

[0046] A reinforced concrete rectangular section beam with a strength grade of C30 was made, with a length of 3000mm×width of 250mm×height of 500mm, and the thickness of the protective layer was 30mm. The cement is 42.5 grade ordinary Portland cement produced by a company; the sand is medium sand from a real estate, with a fineness modulus of 2.8 and a mud content of 1.7%; , the mud content is 0.1%, and the bulk density is 1540kg / m 3 ; The concrete mix ratio is shown in Table 1. The longitudinal tensile steel bars are grade II hot-rolled deformed steel bars, and the stirrups are grade I smooth round steel bars.

[0047] Table 1 C30 mix ratio

[0048]

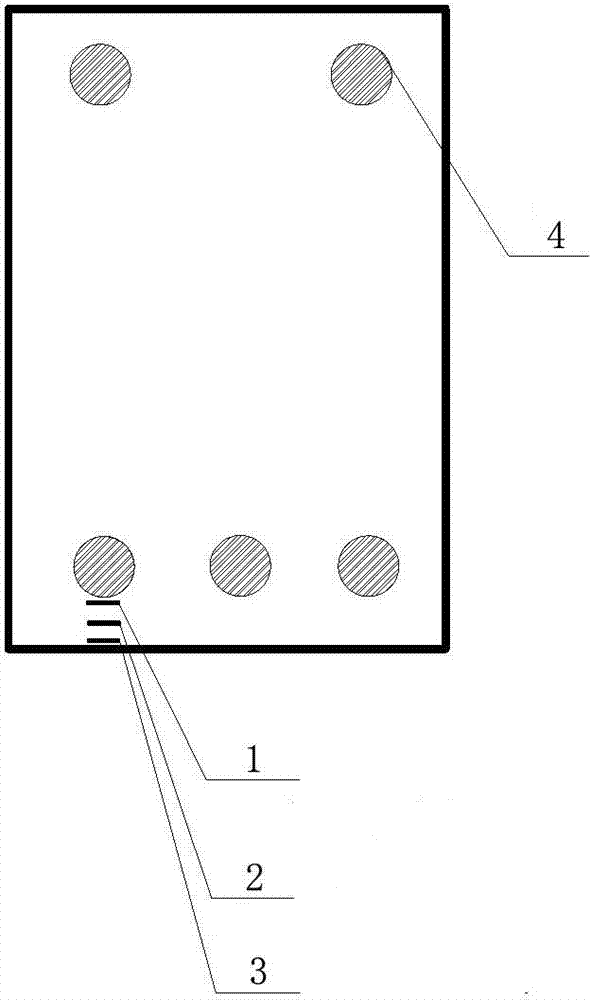

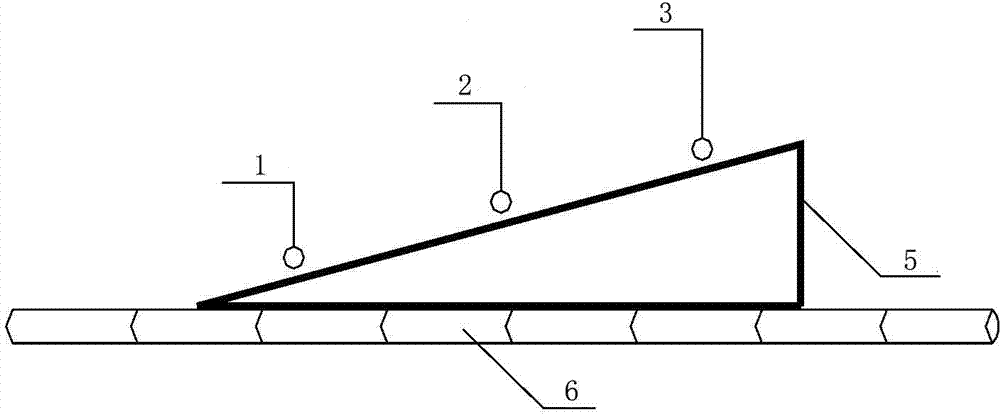

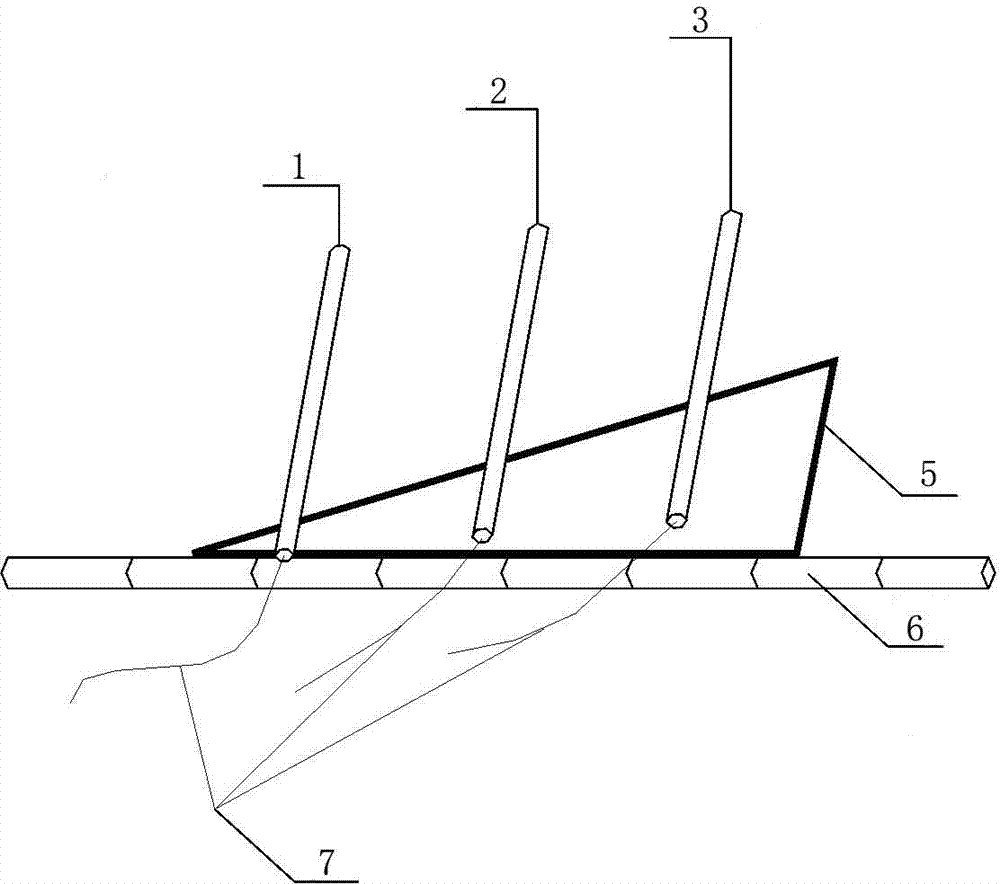

[0049] (2) For the arrangement of reinforcement corrosion monitoring device and its fiber grating in concrete structure, see Figure 1 to Figure 4 :

[0050] In order to accur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com