Variable capacitance-based sensor for corrosion monitoring of steel structure surface and manufacturing method thereof

A corrosion monitoring and sensor technology, applied in the field of corrosion monitoring sensors based on variable capacitance steel structure surface, can solve the problems of increasing local stress concentration factor, reducing material cross-sectional area, reducing mechanical properties, etc., achieving simple structure and convenient installation. , the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

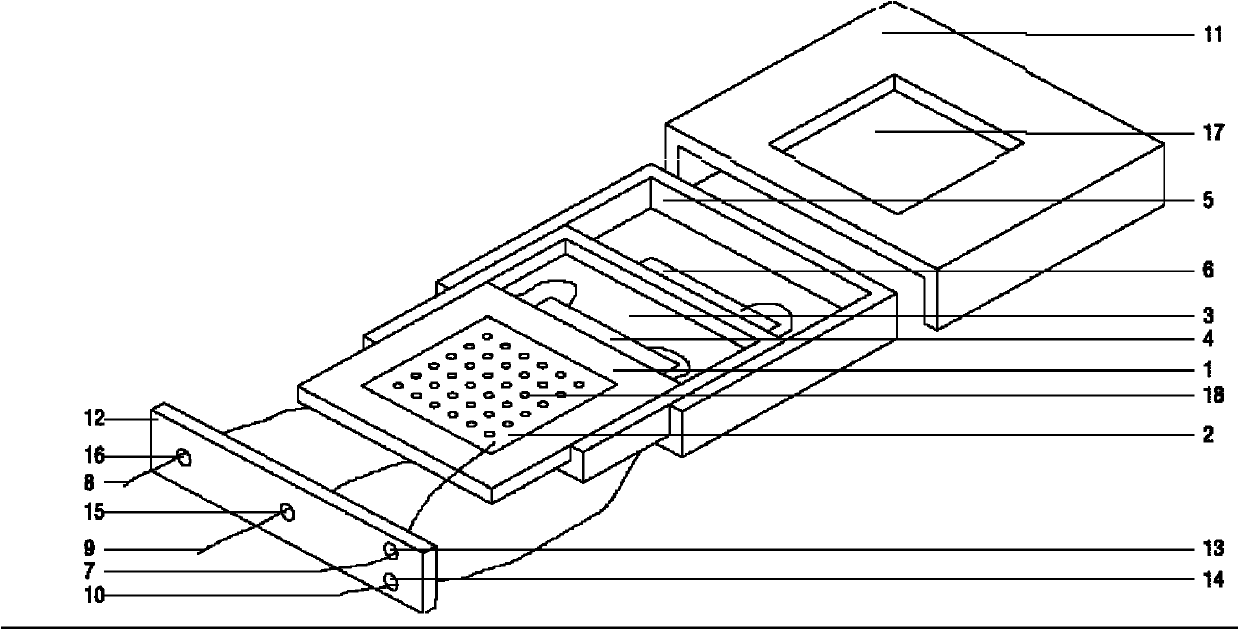

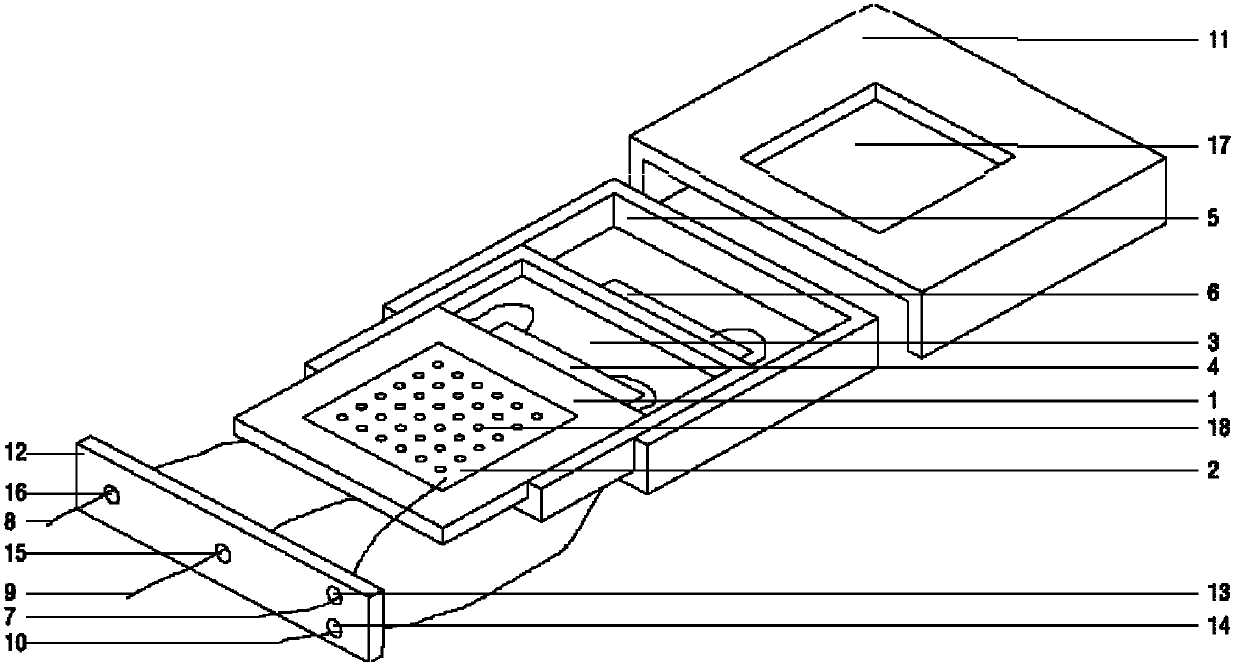

[0019] Below in conjunction with accompanying drawing, the present invention is described in more detail.

[0020] As shown in the accompanying drawings, the surface corrosion monitoring sensor based on variable capacitance steel structure includes an insulating cover 11 with a top opening 17 on the top surface. The insulating cover 11 is a square groove with one wall missing. The upper layer of the sensor, the middle layer of the sensor and the lower layer of the sensor. The upper layer of the sensor is composed of the first insulating dielectric plate 1 and the first corroded steel material layer 2 attached thereto. The first corroded steel material layer 2 has a first lead wire 7 drawn out. The first A drilling area 18 is provided in the middle of the insulating dielectric plate 1, and the middle layer of the sensor is composed of a second insulating dielectric plate 3 and a second corroded steel material layer 4 affixed thereon, and a second lead wire is arranged on the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com