Oil and gas pipeline leakage positioning method based on sound wave amplitude

An acoustic wave amplitude, oil and gas pipeline technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of insufficient applicability of oil pipelines and gas pipelines, uncommon applicability of leak location methods, and increased leak location calculations. It can solve the problems of low positioning accuracy, low cost and avoid installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

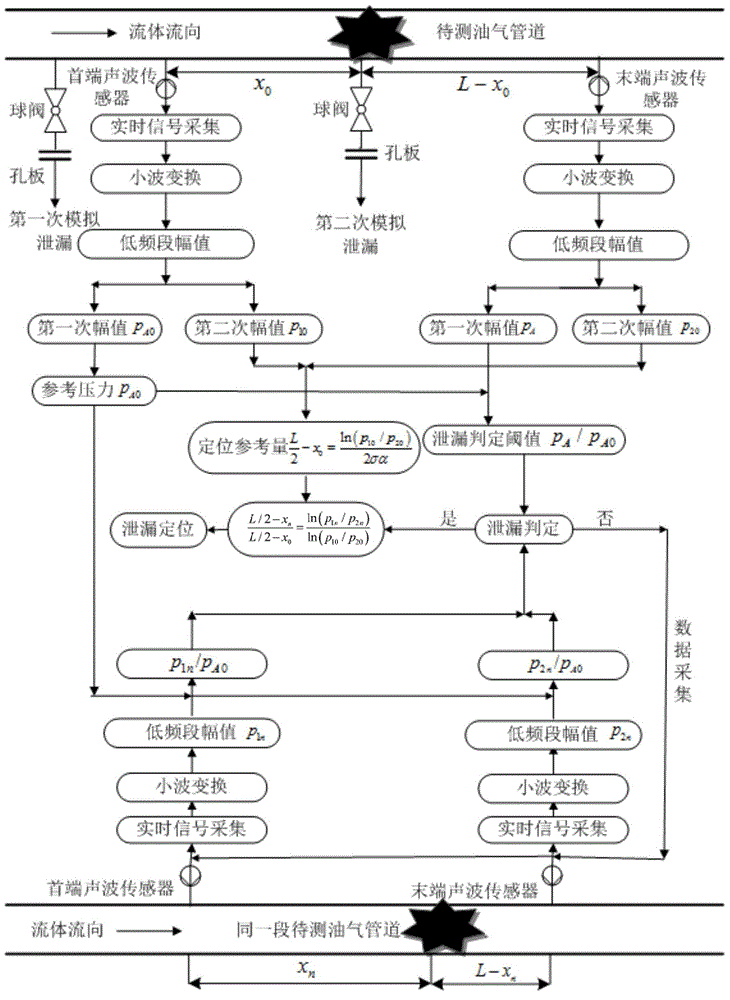

[0033] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

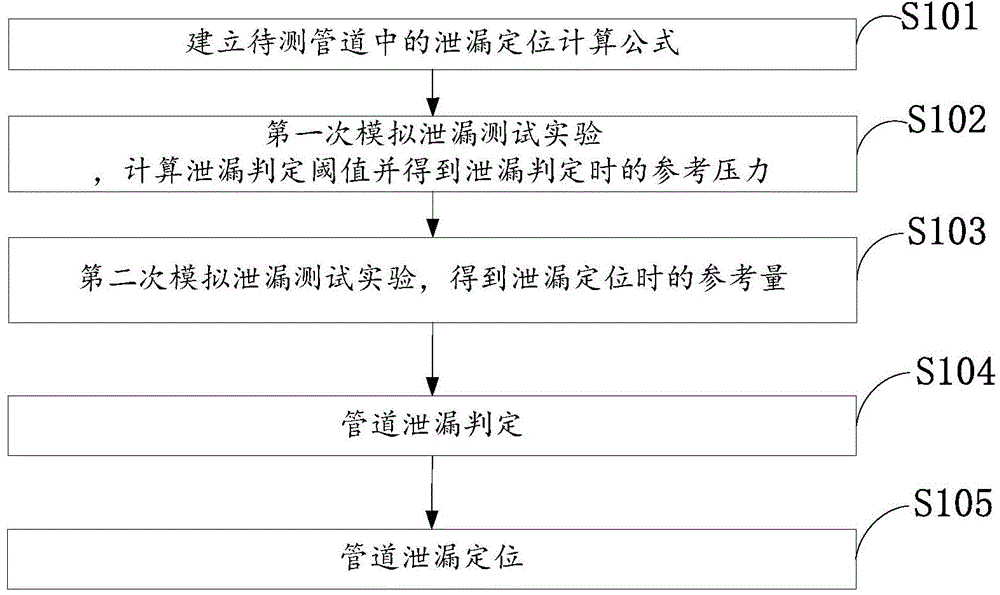

[0034] Such as figure 1 As shown, the oil and gas pipeline leakage location method based on the acoustic wave amplitude attenuation model in the embodiment of the present invention includes the following steps:

[0035]S101: Install a sensor at the beginning and end of the pipeline to be tested, and establish a calculation formula for leak location in the pipeline to be tested;

[0036] S102: Carry out the first simulated leak test experiment, set the minimum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com