Pipeline detection robot

A pipeline detection and robotics technology, applied in the field of robotics, can solve the problems of immature magnetic memory detection technology and achieve the effects of preventing mechanism overload, convenient operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is implemented according to the accompanying drawings, which will be described in detail below in conjunction with the accompanying drawings.

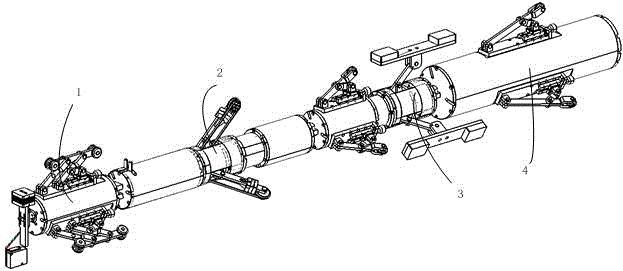

[0021] Such as figure 1 As shown, it is a schematic diagram of the overall structure of a pipeline detection robot of the present invention, wherein: laser detection mechanism 1, traction mechanism 2, electromagnetic ultrasonic mechanism 3, and electronic cabin 4 are connected by connecting hinges to form a modular robot structure.

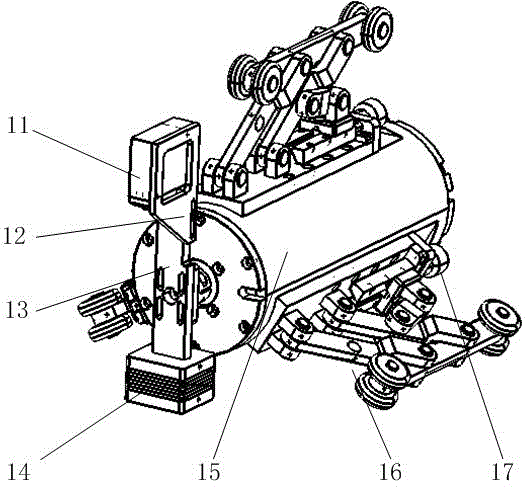

[0022] Such as figure 2 As shown, the laser detection mechanism 1 is composed of a laser displacement sensor 11 , a sensor fixing frame 12 , a rotating arm 13 , a counterweight 14 , a supporting cylinder 15 and a traveling wheel set 16 . The laser detection mechanism 1 adopts the laser point scanning technology, and is centered by the support cylinder 15 and three sets of walking wheels 16, the rotating arm 13 rotates around the center line of the detection robot, the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com