Automatic crawling grinding device for outer wall of circular pipe

An automatic crawling, round tube technology, applied in the direction of grinding automatic control device, grinding drive device, measuring device, etc., can solve the problems of poor grinding quality, pollution, high labor intensity, improve grinding efficiency, avoid human resources, The effect of avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the examples are all in accordance with conventional experimental conditions. In addition, for those skilled in the art, on the premise of not departing from the spirit and scope of the present invention, various modifications or improvements to the material components and dosage in these embodiments all belong to the protection scope of the present invention.

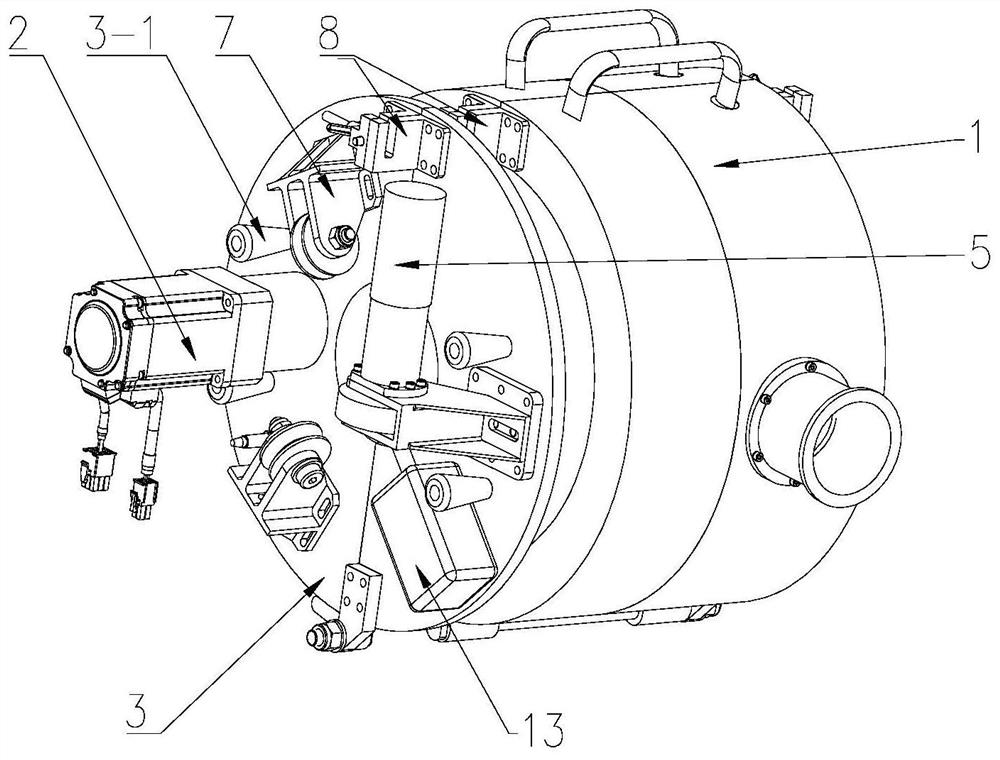

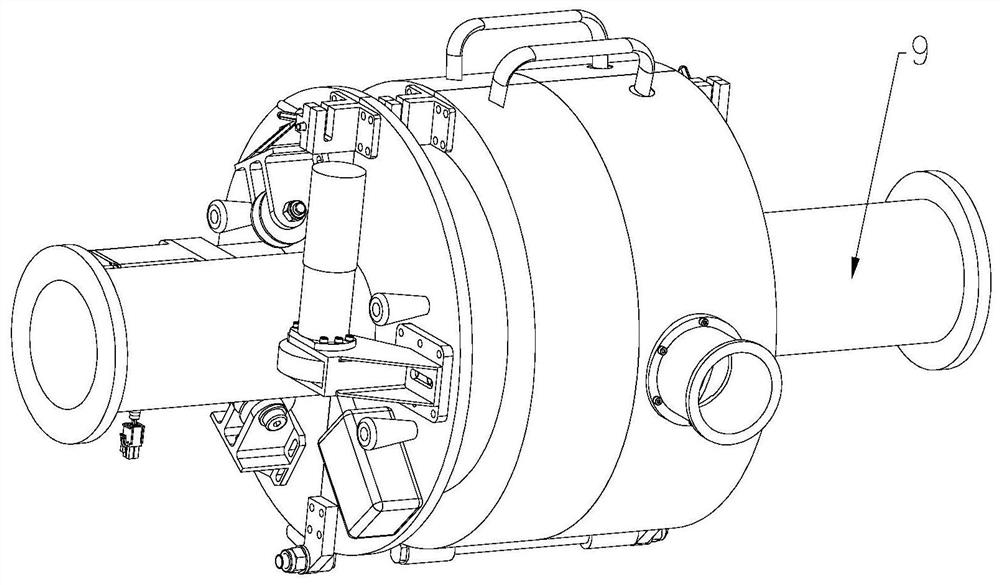

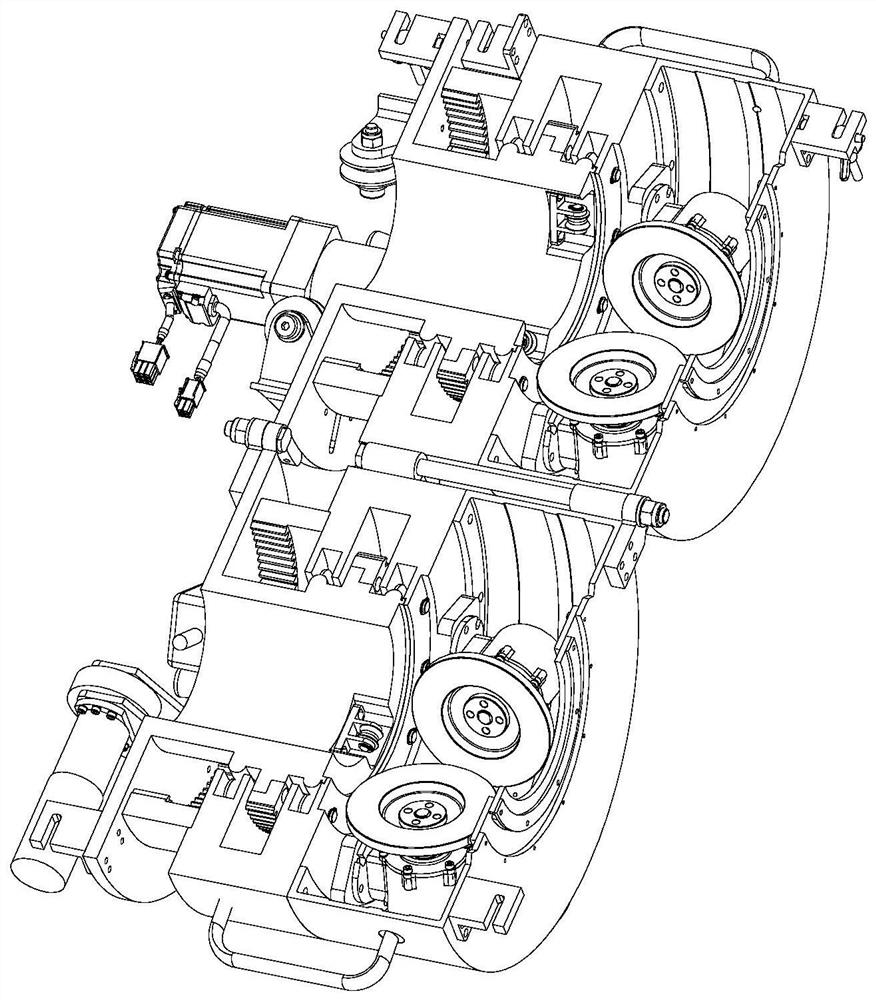

[0041] like Figure 1 to Figure 8 An automatic crawling and grinding device for the outer wall of a circular tube is shown, which includes a housing 1, a main driving module 2, a driving base 3, a grinding module 4 and a crawling module 5, and the housing 1 includes a left side housing 10 and a right side Housing 11, wherein:

[0042] The left side casing 10 and the right side casing 11 are both arranged as semi-cylindrical cylinders that are relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com