Focusing optical system for material machining by means of laser radiation and laser machining head with such focusing optical system

A technology for focusing optical systems and laser processing heads, applied in optics, optical components, manufacturing tools, etc., can solve the problems of high mechanical effort, large number of thermal focus shifts, etc., to achieve the effect of mechanical design and simple mechanical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

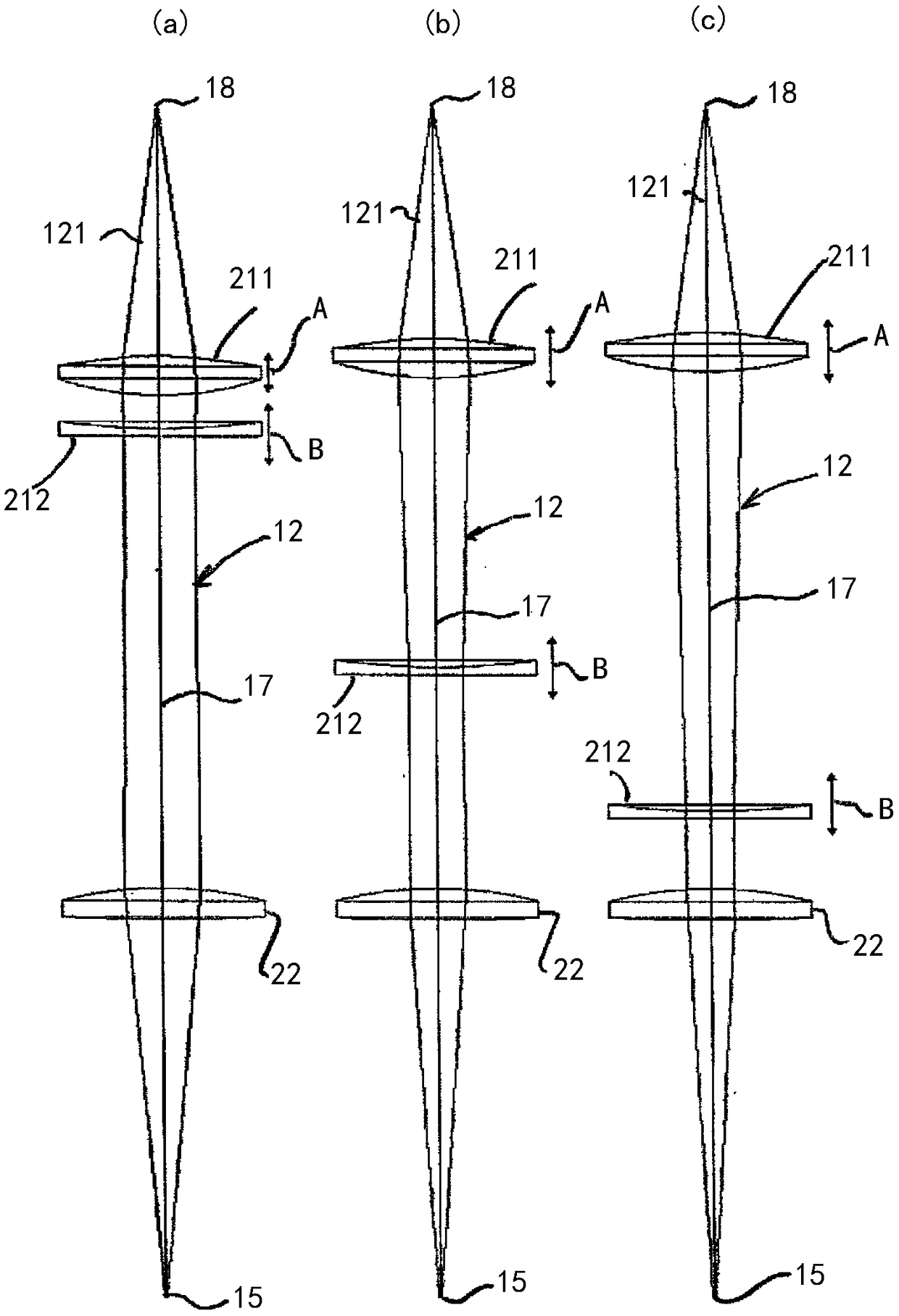

[0021] The same elements are designated with the same reference numerals in the figures.

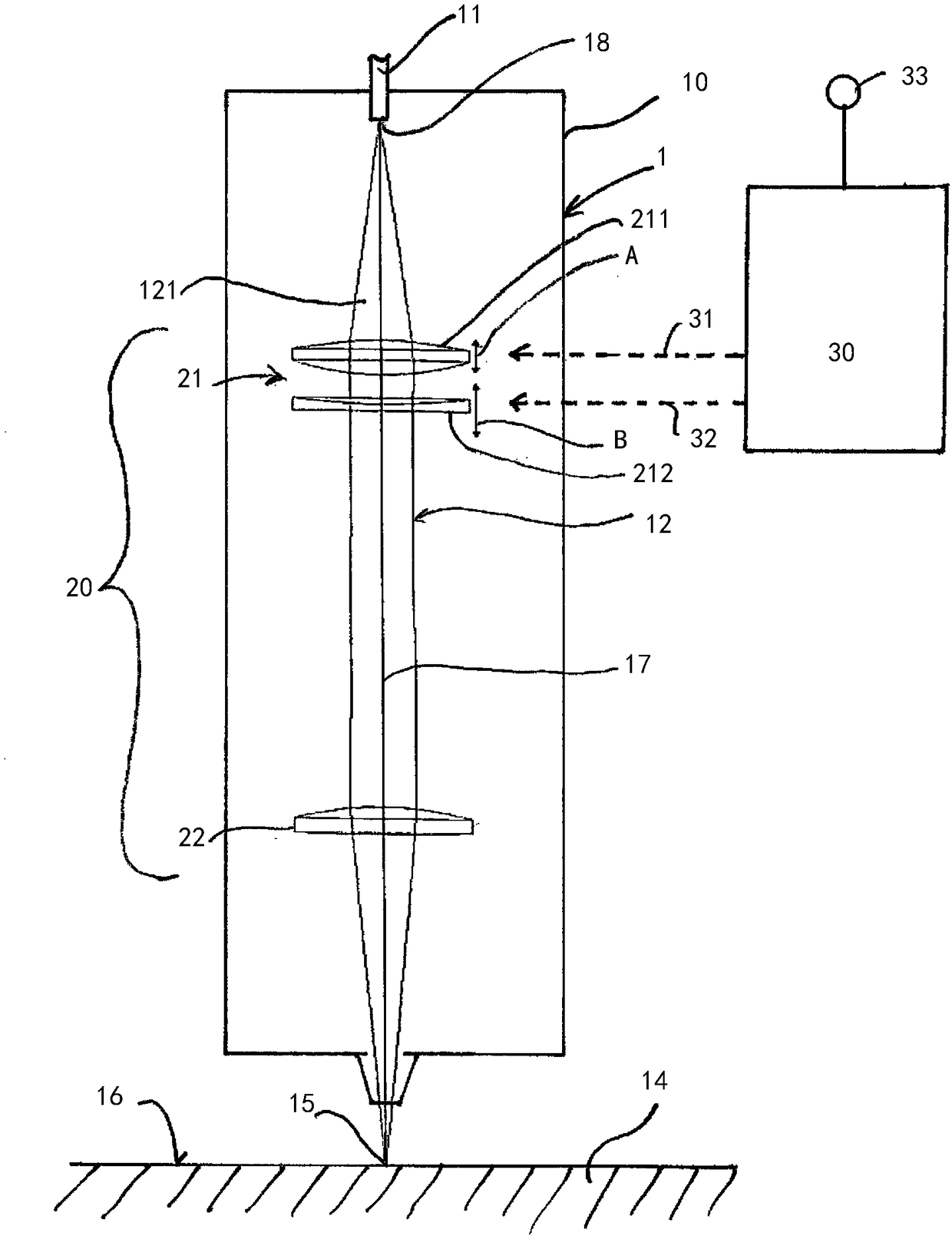

[0022] figure 1 A laser processing head 10 is shown through which a working laser beam 12 supplied via an optical fiber 11 is guided and directed onto a workpiece 14 . The divergent working laser beam 121 output via the optical fiber 11 is focused by means of the focusing optics 20 at the working focal point 15 located on, above or below the surface 16 of the workpiece 14 .

[0023] The focusing optical system 20 includes a collimating optical device 21 and a focusing optical device 22 . The collimating optics 21 consist of a first movable lens or lens group 211 with a positive focal length and a second movable lens or lens group 212 with a negative focal length. Both the first and second movable lenses or lens groups 211, 212 are axially displaceable (as indicated by corresponding arrows) along the optical axis 17 by means of respective actuating drives A, B to thereby adjust the foca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com