Closing unit of a shaping machine

A molding machine and closing force technology, applied in the field of mold clamping units, can solve the problems of increasing movable parts, reducing the accuracy of the half movement of the open-loop control or closed-loop control nut, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

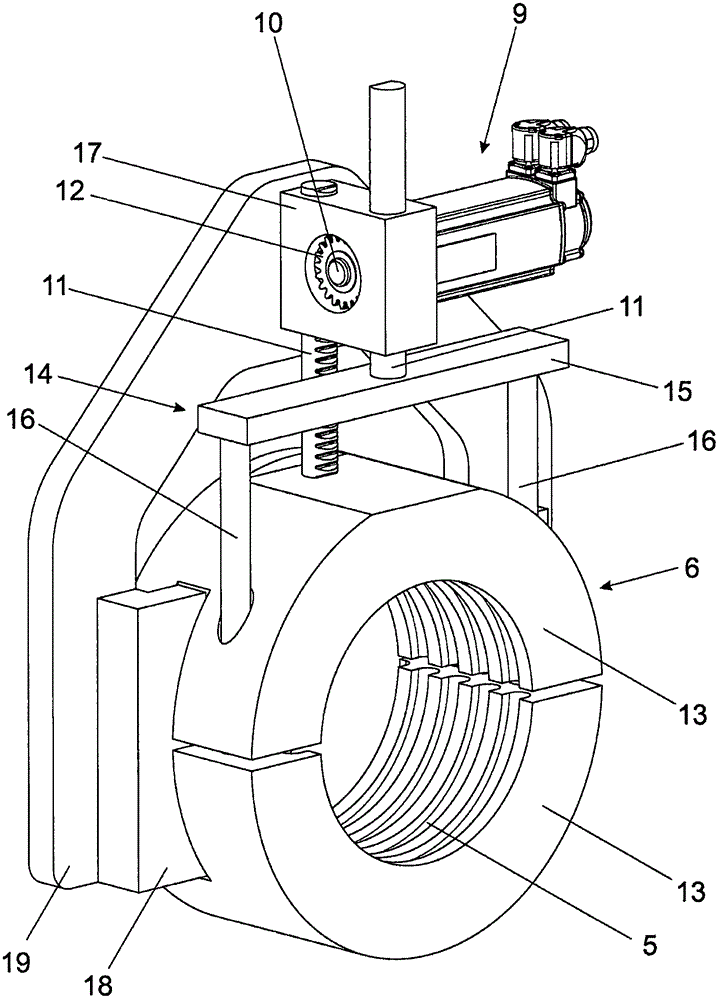

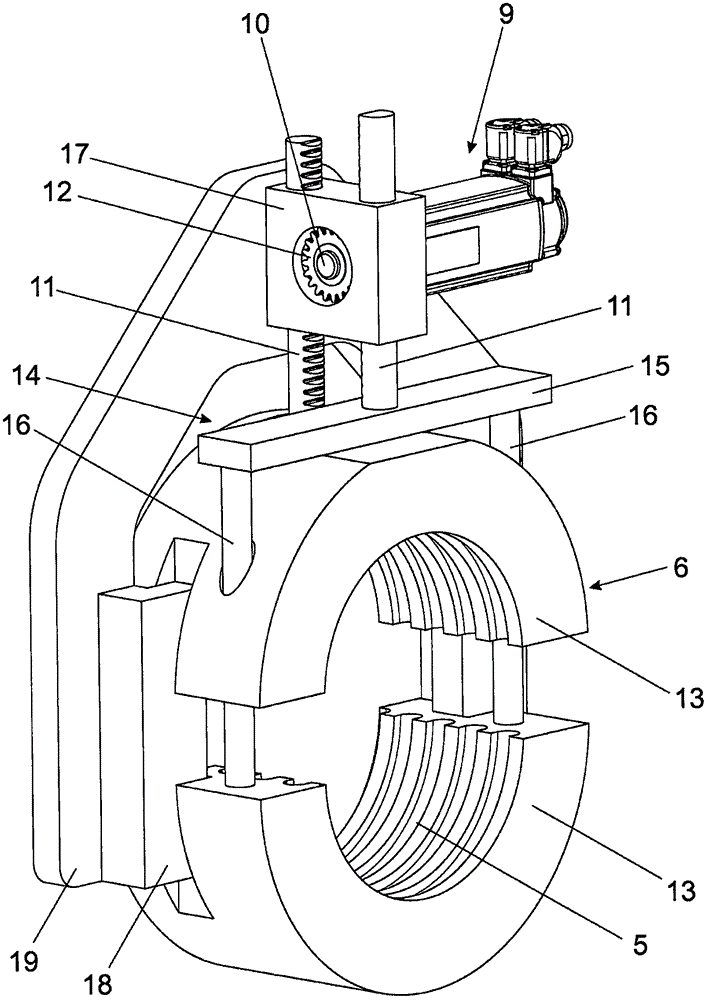

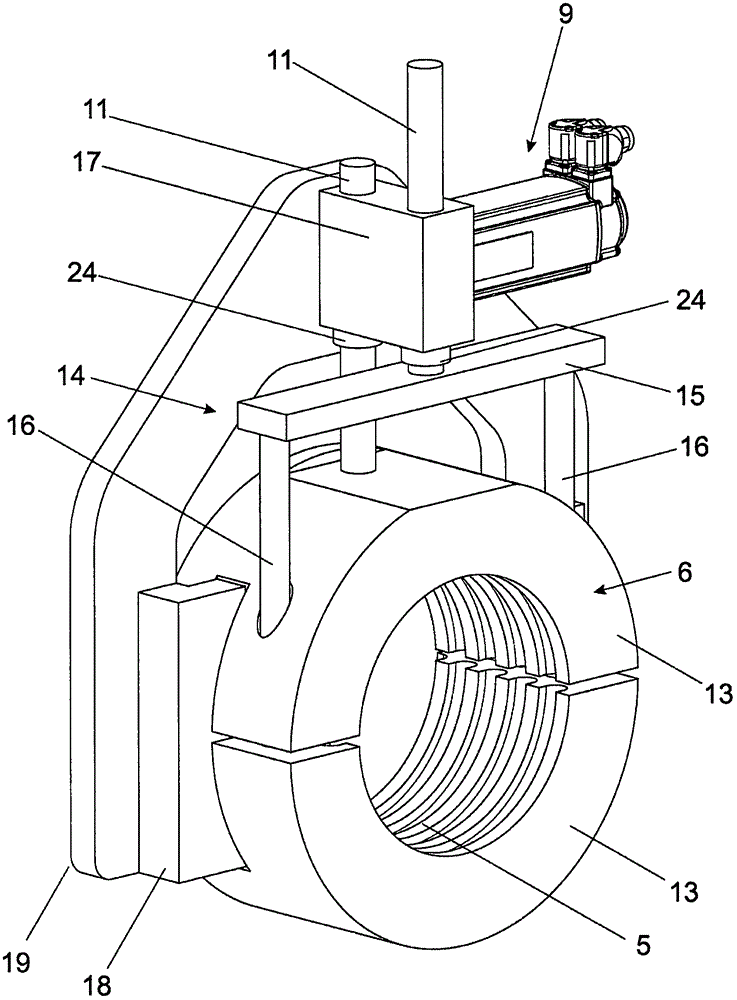

[0030] figure 1 A split nut 6 is shown, the halves 13 of which are each connected to a toothed rack 11 . The rack 11 is driven by the shaft 10 through the meshing portion 8 with the gear 12 . The shaft 10 is rotated here by the servomotor 9 . It can be seen that the lower half 13 of the union nut 6 in the figure is connected to the corresponding toothed rack 11 via a bypass element 14 . The circumvention element 14 basically comprises a bridge element 15 and two rod elements 16 . The rod 16 partially passes through the upper half 13 of the union nut 6 in the figure. This produces an additional guidance of the upper half 13 of the union nut 6 . A gear 12 cooperating with a toothed rack 11 via a toothing 8 is arranged in a housing 17 . Housing 17 is fixed on flange 19 . Flange 19 is connected with the piston member 23 of closing power cylinder or is fixed on it (see also Figure 5 ).

[0031] Furthermore, the flange 19 is connected to a guide 18 which cooperates with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com