Ground drilling hammer and the driving method

A drilling and hammer technology, which is used in the field of drilling hammers and drives for excavation, can solve the problems such as the compressed air function is not effectively performed, the drilling equipment is not easy to repair and maintain, and it is broken or damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

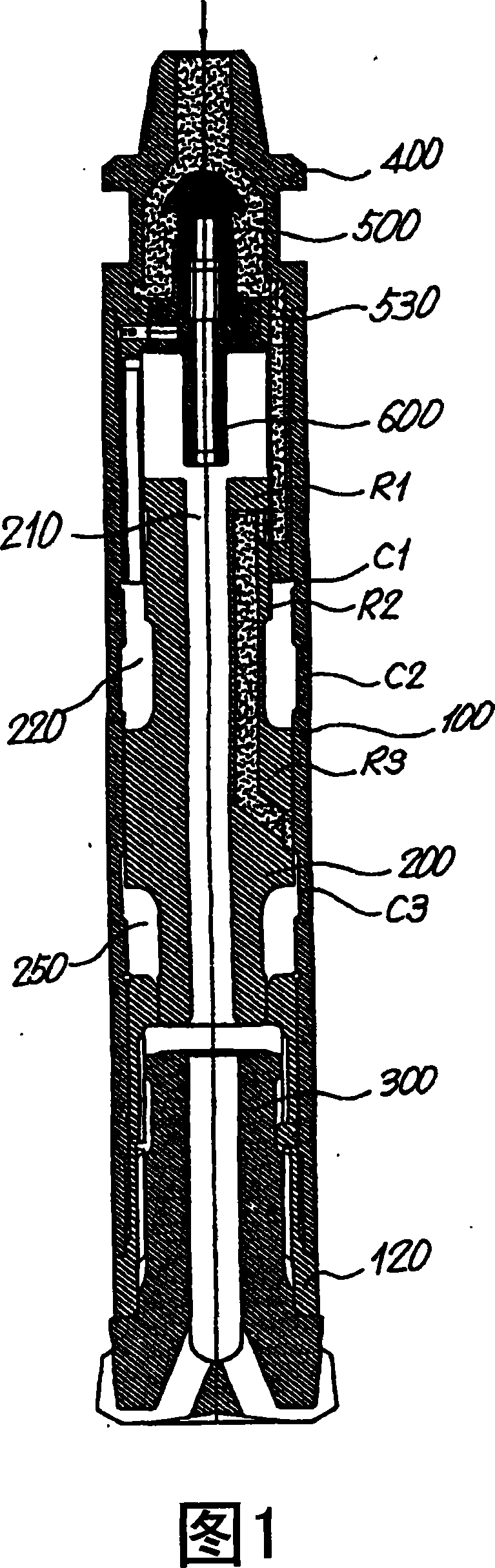

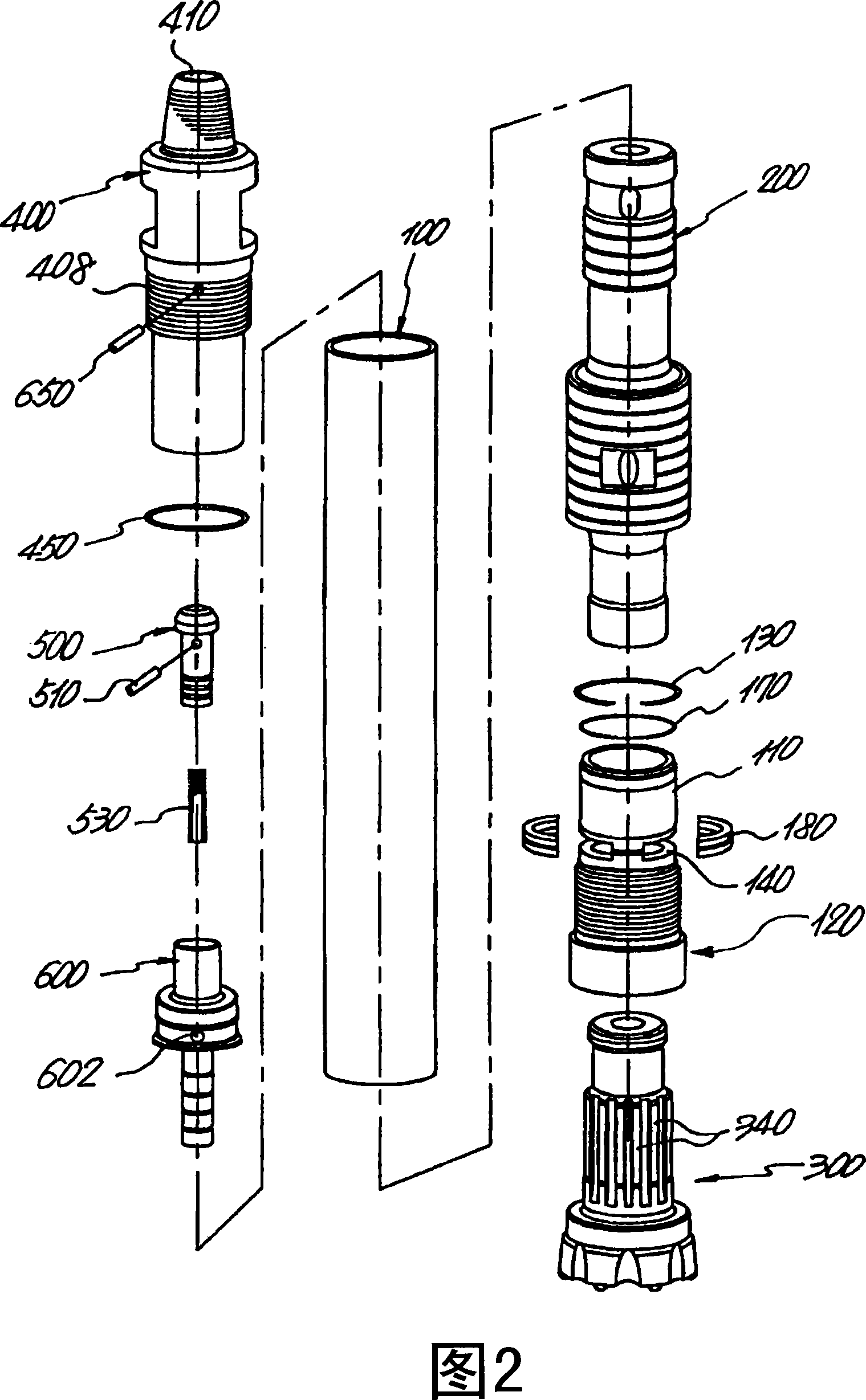

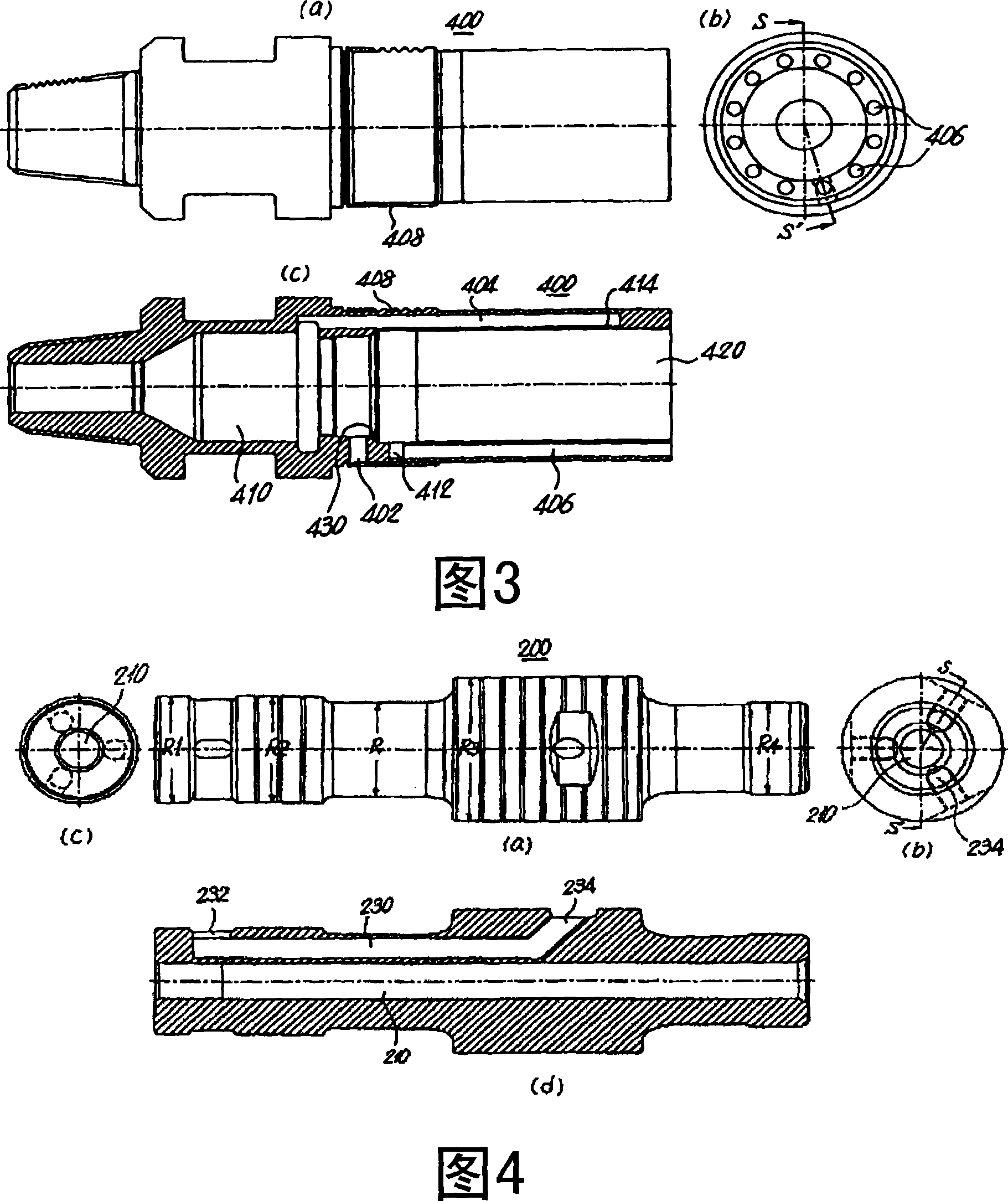

[0036] Fig. 2 is an exploded perspective view of the pneumatic hammer for rock drilling in an assembled state according to the first embodiment of the present invention.

[0037] With reference to Fig. 2, have shown the rear hammer head 400 that is suitable for being installed on the inner circumference of the upper end of piston sleeve 100, O type ring 450, check valve 500, pin 510, the inner hole that is suitable for being installed in check valve 500 The coil spring 530 of 520, and the guide body 600 having the stop hole 602 formed in its outer peripheral surface, are disassembled in this order. In this example, the piston 200 and the chuck 120 are mounted to the lower end of the piston casing 100, and it is shown that the hammer head 300 performs drilling work due to collision with the piston 200. Referring to FIG. Reference numerals are not explained in FIG. 2 , reference numeral 110 designates a bushing, 130 designates a stop ring, reference numeral 140 designates a hamm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com