Machine head structure of knitting flat machine

A technology of flat knitting machine and machine head, which is applied to knitting, flat knitting machine with individual moving needles, weft knitting, etc. It can solve the problems of not being able to drive at the same time, the limitation of knitting patterns, and cumbersomeness, so as to improve productivity and product quality. The effect of convenient density adjustment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

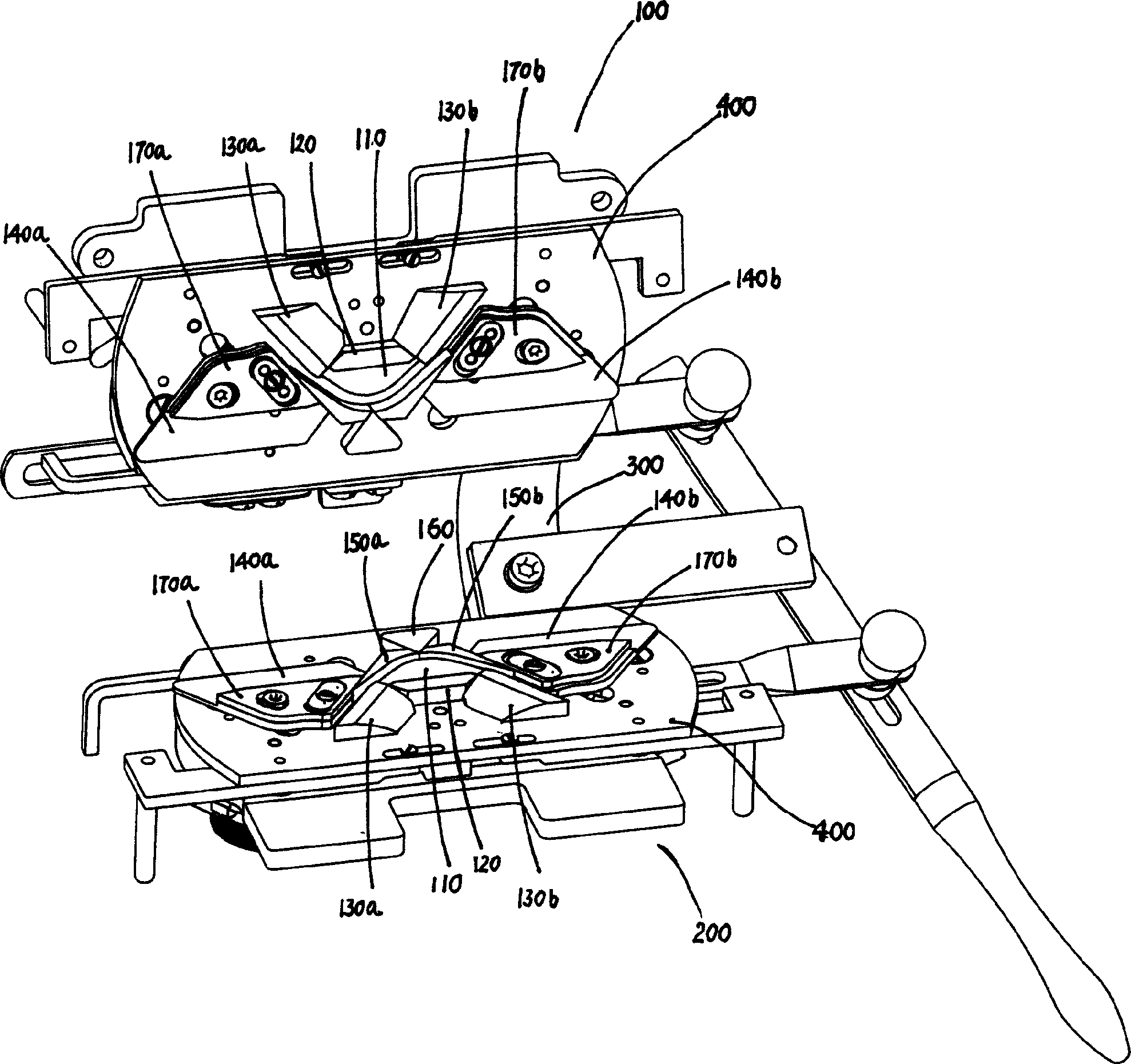

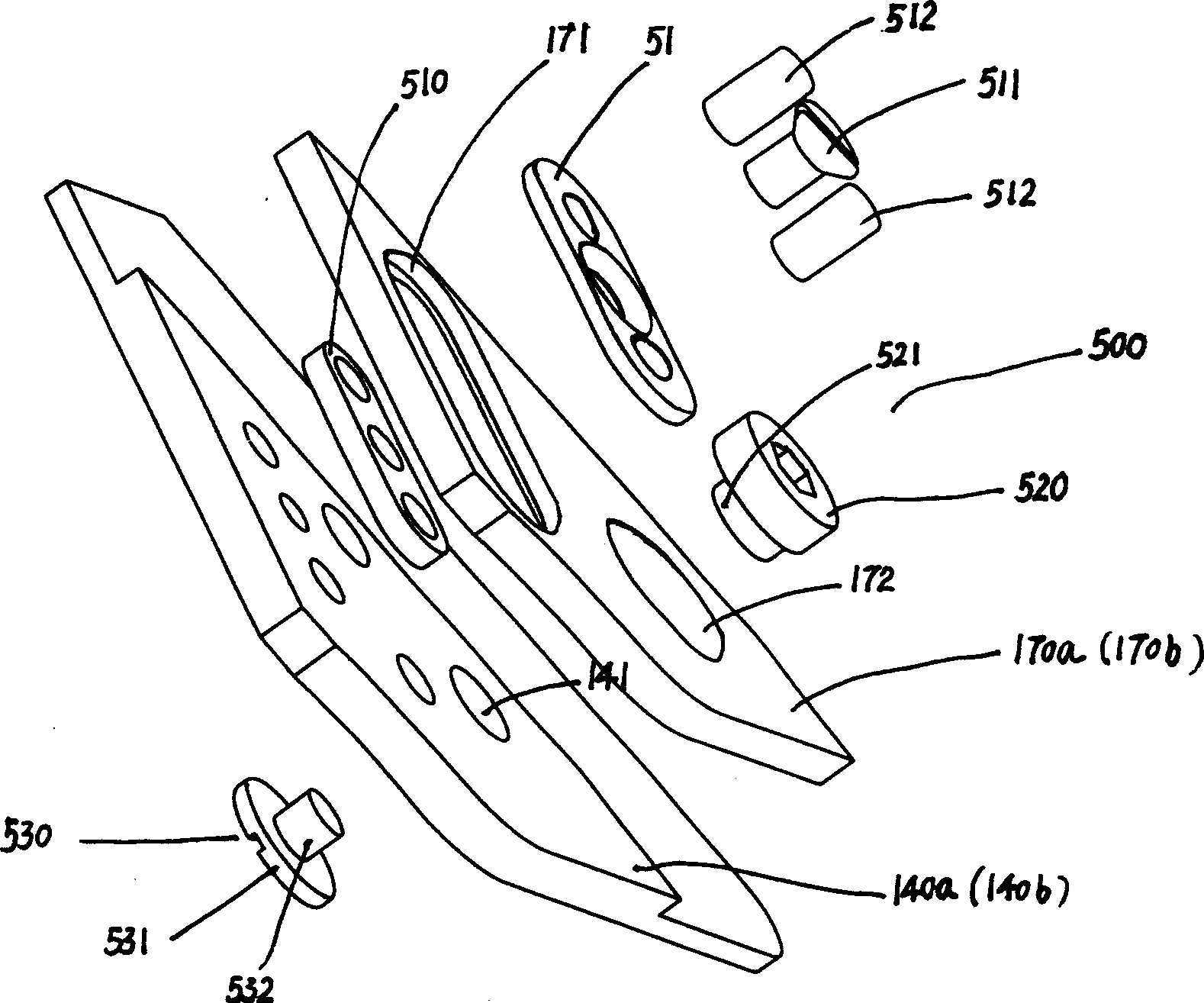

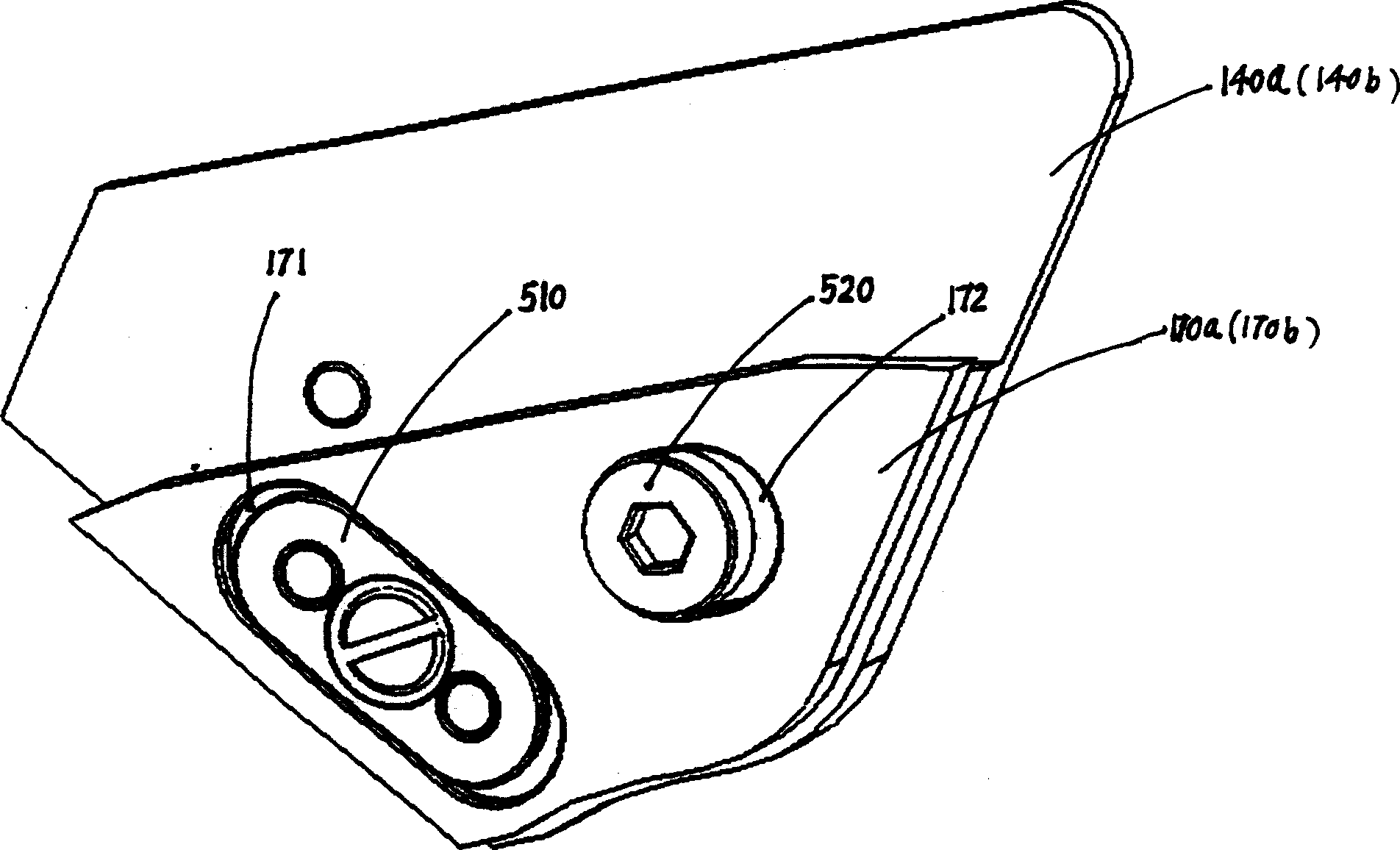

[0039] See shown in accompanying drawing 1, the present invention comprises the front head 100 that cooperates with front and rear needle bed and rear head 200 to form, and front and rear head 100 and 200 link to each other by connecting arm 300, front head 100 and rear machine The bottom plate 400 of the head 200 is respectively provided with a central jacquard cam 110, a fixed cam 120, a needle starting cam 130a and 130b, a large yarn bending cam 140a and 140b, a left and a right herringbone cam 450a and 150b and a return stitch cam 160, wherein , a needle-starting triangle 130a, a central jacquard triangle 110, one side edge of the needle-starting triangle 130a, a large yarn-bending triangle 140a, a left herringbone triangle 150a, a back-stitching triangle 160, a right herringbone triangle 150b, and a large yarn-bending triangle 140b. The side edges form a needle trajectory that meets the technical points of each weaving requirement.

[0040] A movable yarn bending triangle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com