Machine-room-less speed limiter for elevator

A machine room-less and speed limiter technology, which is applied in elevators, hoisting devices, transportation and packaging, etc., can solve problems such as large noise, hidden dangers of reset system failure, ratchet damage, etc., to achieve noise elimination, wide application range, and high speed stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

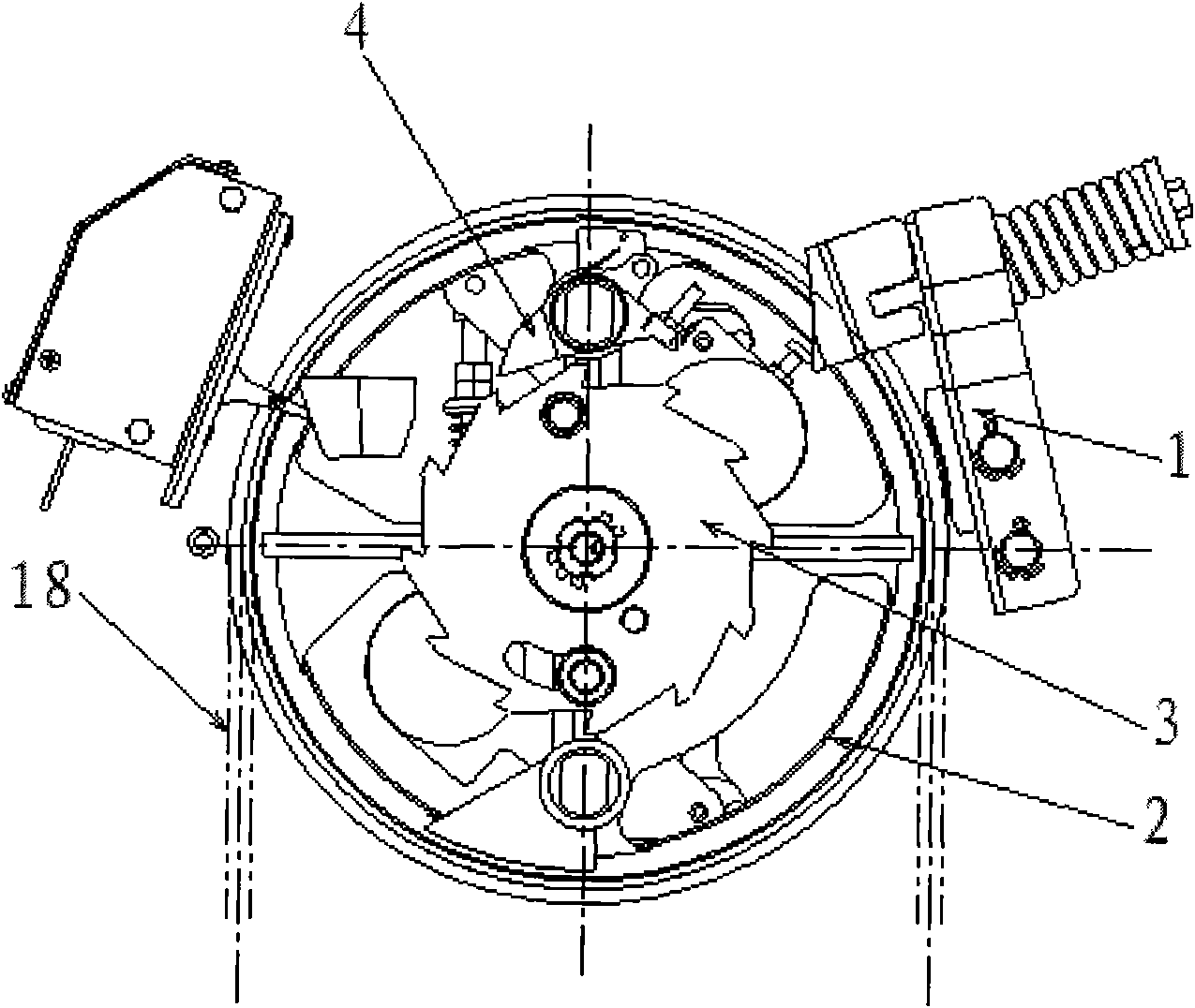

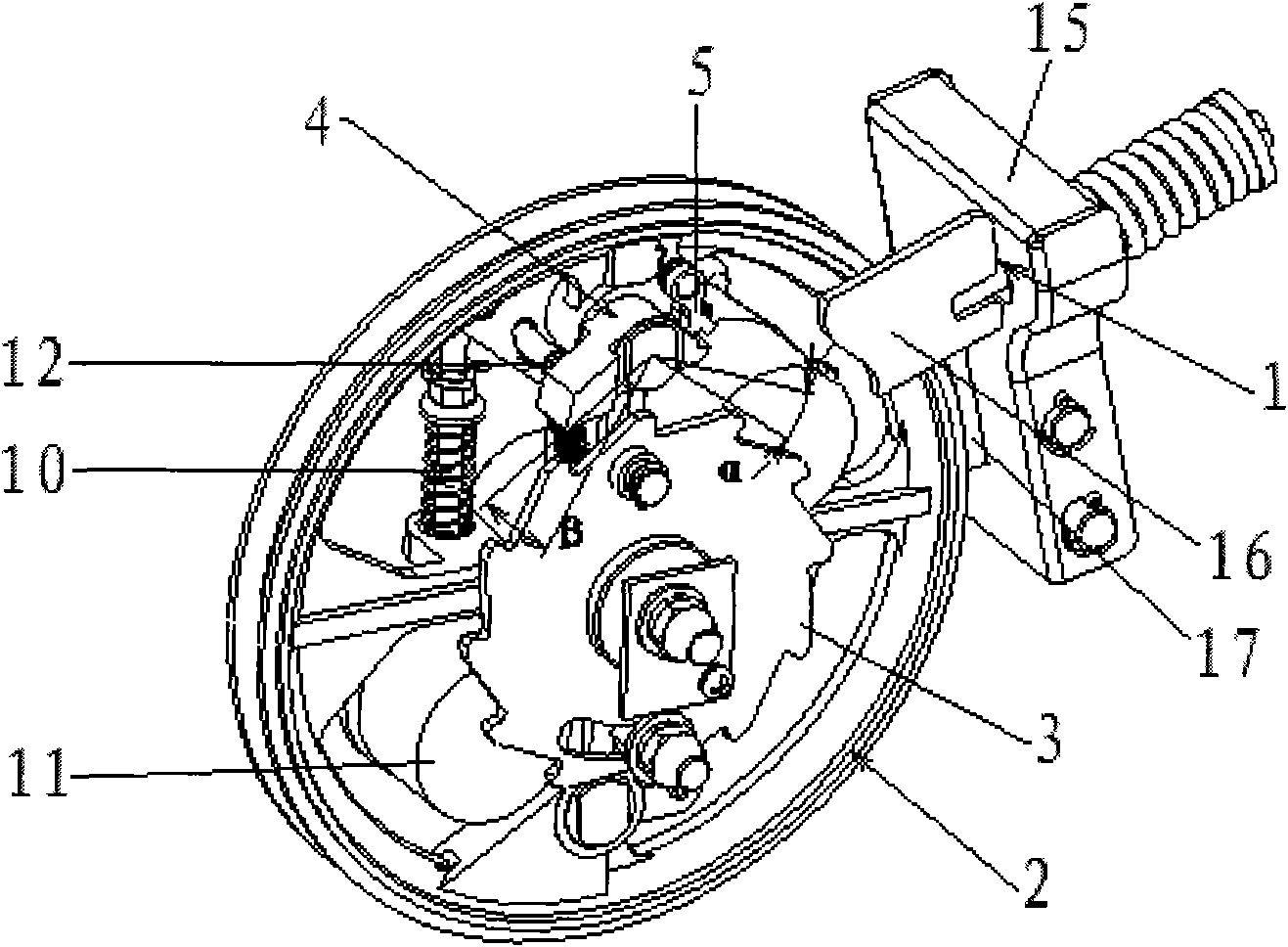

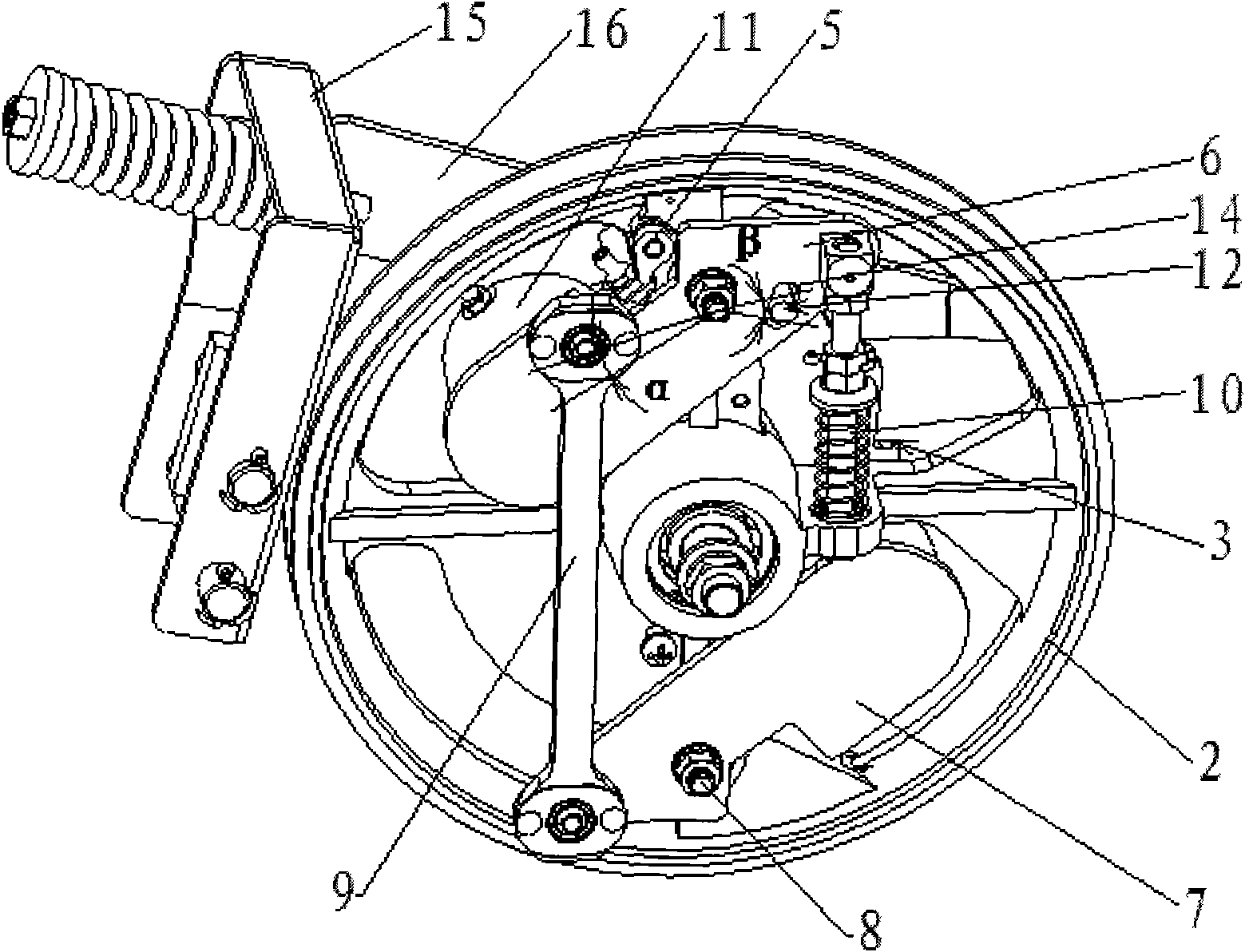

[0020] Such as figure 2 , 3 As shown, a machine room-less speed governor for an elevator comprises a frame, a limit switch arranged on the frame, a brake mechanism 1, a cable pulley 2 and a ratchet 3, a centrifugal mechanism arranged on the cable pulley 2, and a The rotating ratchet 4 and the anti-retraction head fork 5 that is stuck against the tail end of the ratchet 4, the ratchet 3 is in transmission connection with the brake mechanism 1, and the centrifugal mechanism includes an upper centrifugal plate 6, a lower centrifugal sheet 7, two centrifugal hammer shafts 8, connecting rod 9 and compression spring 10, the front part of the upper centrifugal sheet 6 and the lower centrifugal sheet 7 is provided with a centrifugal weight 11, and the anti-retraction head fork 5 passes through The torsion spring is fixed on the cable pulley 2, and the anti-retraction head fork 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com