Cathode material of manganese, cobalt and lithium oxidate for lithium ion battery and preparation method of cathode material

A battery manganese cobalt lithium and cathode material technology, applied in battery electrodes, cobalt oxide/cobalt hydroxide, circuits, etc., can solve the problems of deterioration of electrochemical performance of cathode materials, poor repeatability of co-precipitation process, and unfavorable large-scale production. , to achieve the effects of excellent electrochemical performance, easy control and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Li 1.2 mn 0.4 co 0.4 o 2 Cathode material

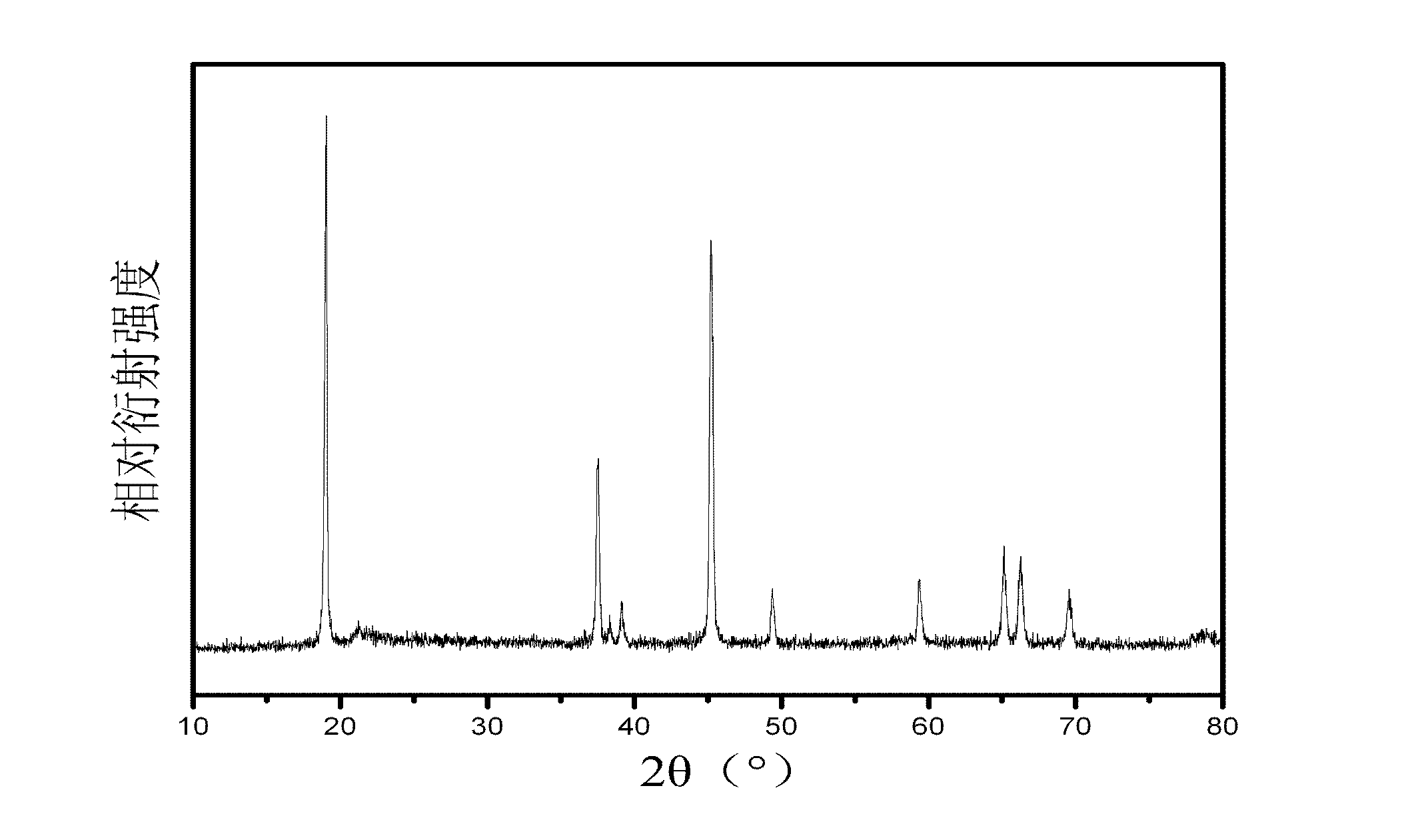

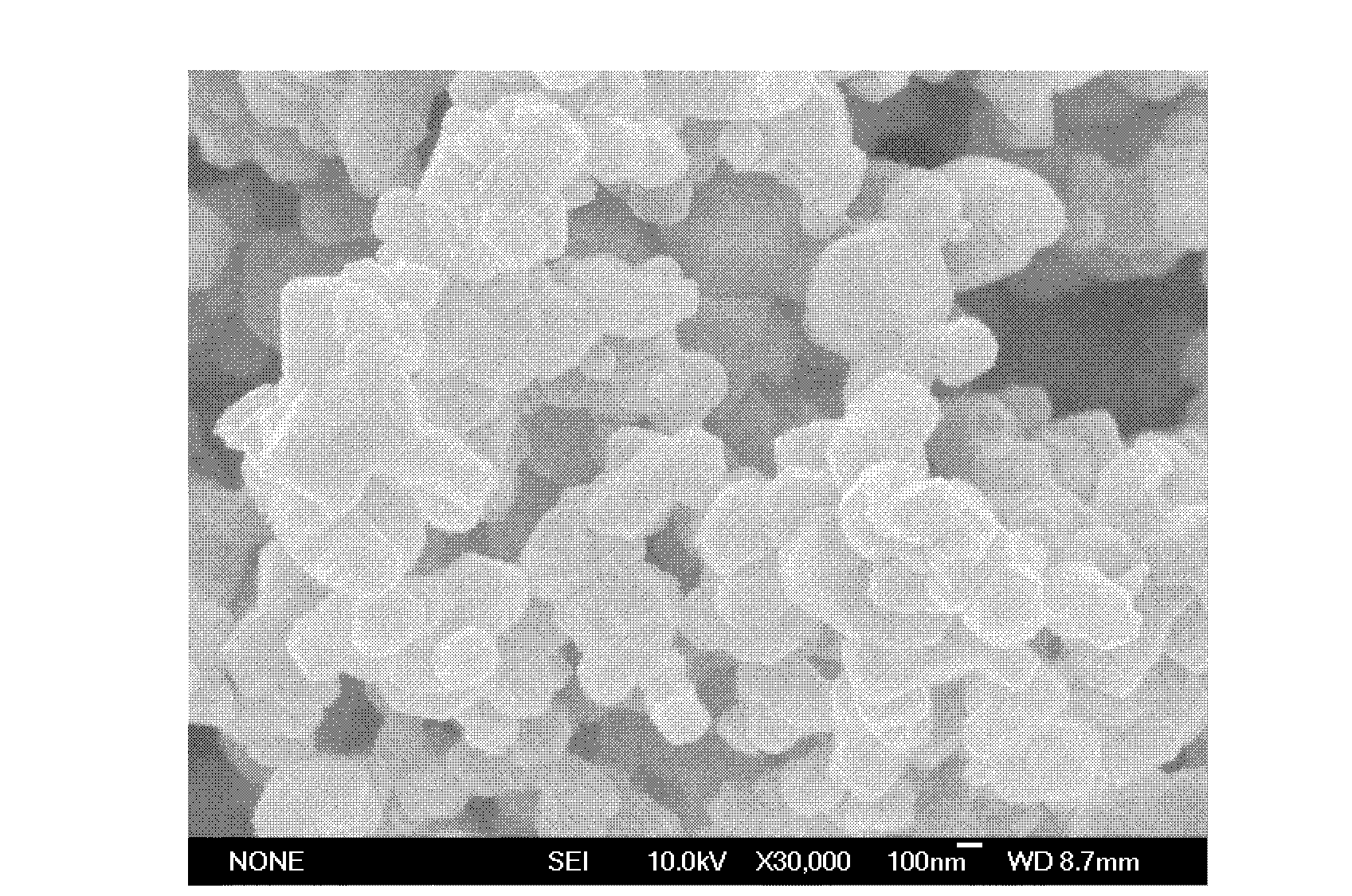

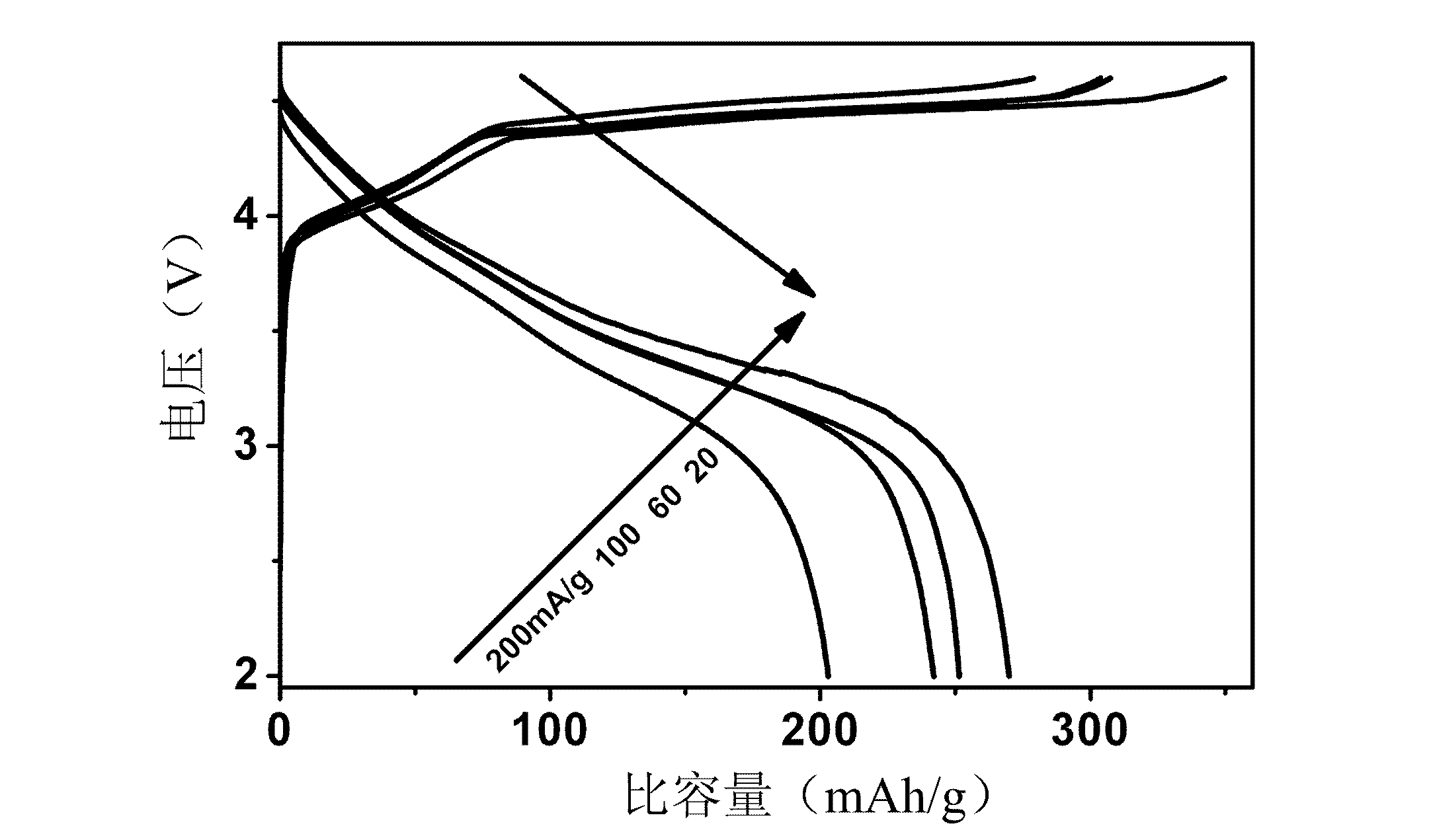

[0024] With lithium acetate, manganese acetate, cobalt acetate and oxalic acid as starting materials, 0.9804g manganese acetate, 0.9964g cobalt acetate, and 1.2855g lithium acetate are dissolved in absolute ethanol to obtain a metal salt solution of ethanol; Dissolve 2.1634g of 20% excess oxalic acid in absolute ethanol; add the ethanol solution of oxalic acid into the metal salt solution of ethanol, stir for 1 hour, suction filter and dry at 100°C for 3 hours, then grind it into powder and put it into a crucible; In the furnace, heat up to 900°C at a heating rate of 4°C / min for 12 hours, and anneal at room temperature to obtain Li 1.2 mn 0.4 co 0.4 o 2 Powder material. The XRD test results of powder materials show that the synthesized powder has a layered rock-salt structure (R3m), such as figure 1 shown. The SEM test results of powder materials show that the synthetic powder particles are evenly distribu...

Embodiment 2

[0025] Example 2: Li 1.033 mn 0.067 co 0.9 o 2 Cathode material

[0026] With lithium acetate, manganese acetate, cobalt acetate and oxalic acid as starting materials, 0.3270g manganese acetate, 4.4836g cobalt acetate, and 2.5305g lithium acetate are dissolved in absolute ethanol to obtain a metal salt solution of ethanol; Dissolve 4.8021g of 20% excess oxalic acid in absolute ethanol; add the ethanol solution of oxalic acid into the metal salt solution of ethanol, stir for 1 hour, suction filter and dry at 100°C for 3 hours, then grind it into powder and put it into a crucible; In the furnace, heat up to 900°C at a heating rate of 4°C / min for 12 hours, and anneal at room temperature to obtain Li 1.033 mn 0.067 co 0.9 o 2 Powder material. The XRD test results of powder materials show that the synthesized powder has a layered rock-salt structure (R3m). The SEM test results of powder materials show that the synthesized powder particles are evenly distributed, and the pa...

Embodiment 3

[0027] Example 3: Li 1.1 mn 0.2 co 0.7 o 2 Cathode material

[0028] With lithium acetate, manganese acetate, cobalt acetate and oxalic acid as starting materials, 0.9804g manganese acetate, 3.4873g cobalt acetate, and 2.4689g lithium acetate are dissolved in absolute ethanol to obtain a metal salt solution of ethanol; Dissolve 6.3842g of 20% excess oxalic acid in absolute ethanol; add the ethanol solution of oxalic acid into the metal salt solution of ethanol, stir for 1 hour, filter with suction and dry at 100°C for 3 hours, then grind it into powder and put it into a crucible; In the furnace, heat up to 900°C at a heating rate of 4°C / min for 12 hours, and anneal at room temperature to obtain Li 1.1 mn 0.2 co 0.7 o 2 Powder material. The XRD test results of powder materials show that the synthesized powder has a layered rock-salt structure (R3m). The SEM test results of powder materials show that the synthesized powder particles are evenly distributed, and the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com