Sorting method for low-grade wolframite and scheelite

A black and white tungsten, low-grade technology, applied in the field of black and white tungsten ore separation, can solve the problems of low recovery rate, low concentrate grade, labor cost and increased investment, so as to reduce the loss of useful ore, improve grade and recovery The effect of increasing the rate and improving the ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

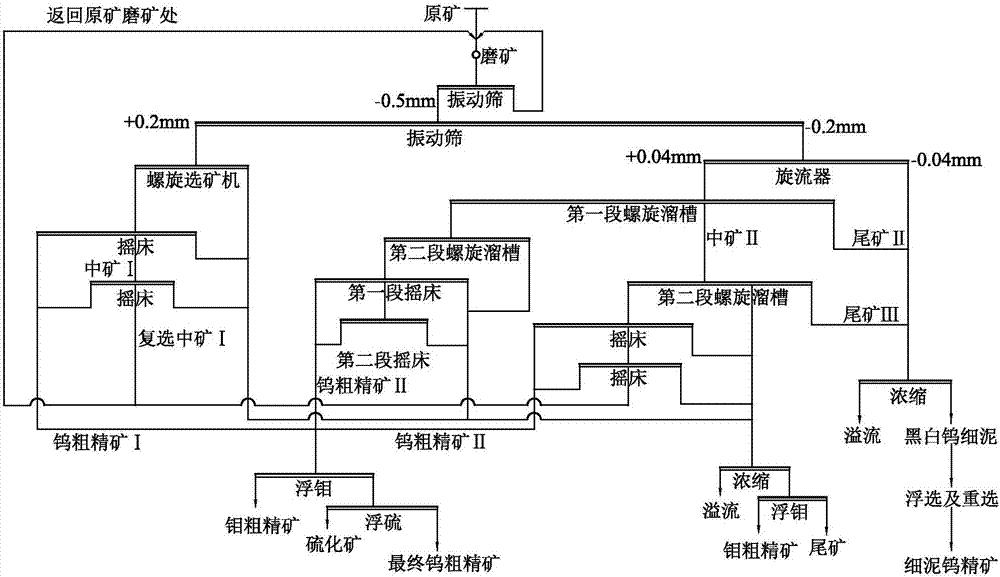

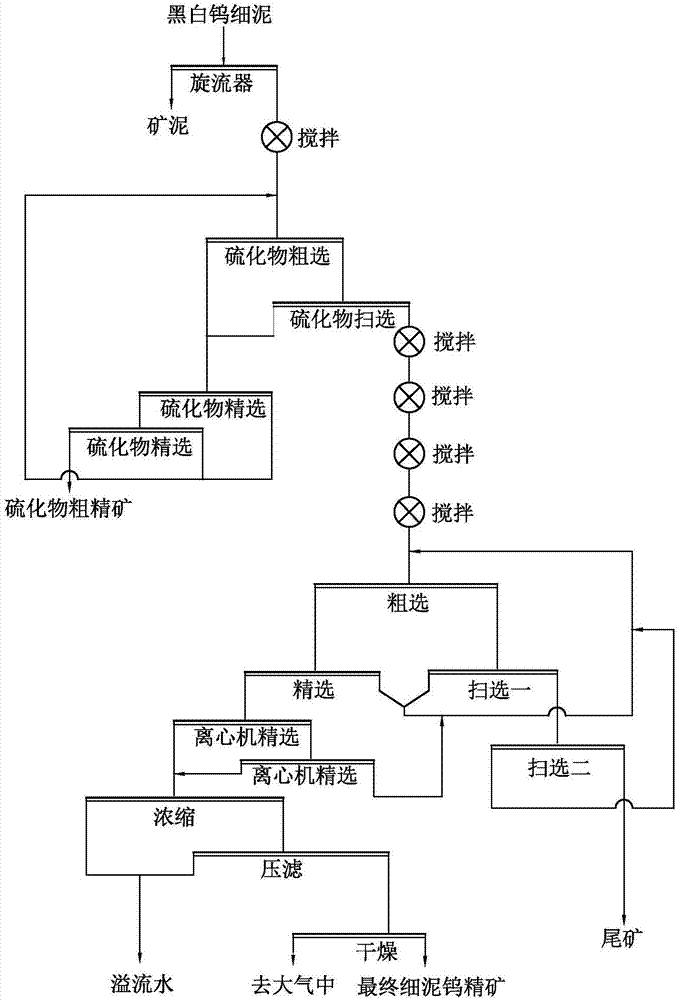

[0028] Please refer to figure 1 , WO of low-grade black and white tungsten ore 3 Most grades are between 0.1% and 0.3%, WO 3 The average grade is 0.233%. The method for sorting low-grade black and white tungsten ore of the present invention includes crushing black and white tungsten ore, grinding and grading, gravity separation and flotation. The raw ore adopts rod mill equipment and high-frequency fine screen to form a closed-circuit grinding process. The first high-frequency fine screen is used to screen the black and white tungsten ore after the rod mill to obtain black and white tungsten ore with a particle size of less than 0.50mm. After the black and white tungsten ore passes through the second high-frequency fine sieve, the black and white tungsten ore with a particle size of less than 0.20mm is screened out. The ore is classified by a hydrocyclone, the overflow part is black and white tungsten ore with a particle size of less than 0.04mm, and the sand part is black a...

Embodiment 2

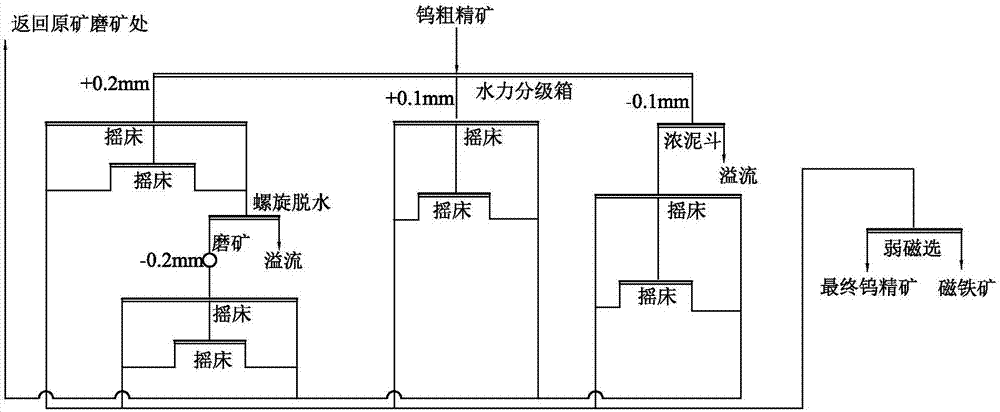

[0041] Such as figure 2 As shown, the difference between the low-grade black and white tungsten separation method in embodiment two and embodiment one is that it also includes secondary classification and gravity separation of the final tungsten rough concentrate. The tungsten coarse concentrate is divided into three grades with a particle size greater than 0.20 mm, a particle size greater than or equal to 0.10 mm and less than 0.20 mm, and a particle size smaller than 0.10 mm through a hydraulic classification box.

[0042] Tungsten coarse concentrate with a particle size greater than or equal to 0.20mm is concentrated by a shaking table to obtain tungsten concentrate and tailings. After spiral dehydration, the tailings are ball milled to obtain tungsten ore with a particle size of less than 0.20mm. The tungsten Tungsten concentrates are obtained after the ore is concentrated on a shaking table. Because the tailings of coarse tungsten concentrates with a particle size greate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com