Method for preparing low-loss wolframite-structure microwave dielectric ceramic by means of reaction sintering technology

A microwave dielectric ceramic and wolframite technology, which is applied in the field of electronic information materials and components, can solve the problems of prolonged preparation time, complicated preparation experiment process, increased preparation cost, etc. The effect of firing and secondary ball milling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

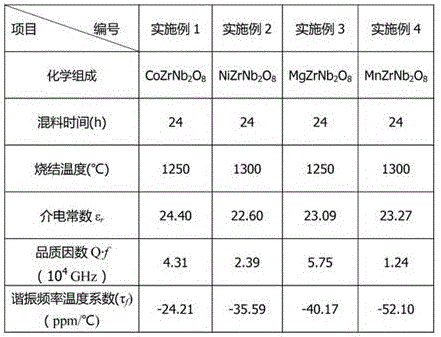

Embodiment 1

[0019] (1) Mixing: according to CoZrNb 2 o 8 For the stoichiometric ratio of the microwave dielectric ceramic phase, 3.2303g of cobalt oxide (CoO) and zirconia (ZrO) with a purity of 99.99% were weighed using a precision balance. 2 ) 5.3122g, and niobium pentoxide (Nb 2 o 5 ) 11.4595g. Pour the weighed powder into a mixing bottle, and add 40g of absolute ethanol and 400g of zirconia grinding balls. The grinding balls with a diameter of 1 cm and a diameter of 0.5 cm are loaded in a mass ratio of 2:1; the mixing bottle of powder, grinding balls and absolute ethanol is placed on the mixer for continuous mixing for about 24 hours, and the mixer The rotation speed is 200r / min; the mixed slurry and the balls are separated by a coarse screen, and the separated slurry is dried in a drying oven at 70-90°C.

[0020] (2) Drying and sieving: put the mixed raw material slurry in a drying oven at 70-90°C for drying, and pass through an 80-mesh sieve after drying to obtain ceramic powde...

Embodiment 2

[0025] (1) Mixing: according to NiZrNb 2 o 8 For the stoichiometric ratio of the microwave dielectric ceramic phase, use a precision balance to weigh 3.2224g of nickel oxide (NiO) with a purity of 99.99%, zirconia (ZrO) 2 ) 5.3147g, and niobium pentoxide (Nb 2 o 5 ) 11.4649g. Pour the weighed powder into a mixing bottle, and add 40g of absolute ethanol and 400g of zirconia grinding balls. The grinding balls with a diameter of 1 cm and a diameter of 0.5 cm are loaded in a mass ratio of 2:1; the mixing bottle of powder, grinding balls and absolute ethanol is placed on the mixer for continuous mixing for about 24 hours, and the mixer The rotation speed is 200r / min; the mixed slurry and the balls are separated by a coarse screen, and the separated slurry is dried in a drying oven at 70-90°C.

[0026] (2) Drying and sieving: put the mixed raw material slurry in a drying oven at 70-90°C for drying, and pass through an 80-mesh sieve after drying to obtain ceramic powder with uni...

Embodiment 3

[0031] (1) Mixing: according to MgZrNb 2 o 8 For the stoichiometric ratio of microwave dielectric ceramic phases, 1.8777g of magnesium oxide (MgO) and zirconia (ZrO) with a purity of 99.99% were weighed using a precision balance. 2 ) 5.7406g, and niobium pentoxide (Nb 2 o 5 ) 12.3837g. Pour the weighed powder into a mixing bottle, and add 40g of absolute ethanol and 400g of zirconia grinding balls. The grinding balls with a diameter of 1 cm and a diameter of 0.5 cm are loaded in a mass ratio of 2:1; the mixing bottle of powder, grinding balls and absolute ethanol is placed on the mixer for continuous mixing for about 24 hours, and the mixer The rotation speed is 200r / min; the mixed slurry and the balls are separated by a coarse screen, and the separated slurry is dried in a drying oven at 70-90°C.

[0032](2) Drying and sieving: put the mixed raw material slurry in a drying oven for drying at 70-90°C, and pass through an 80-mesh sieve after drying to obtain ceramic powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

| Resonant frequency temperature coefficient | aaaaa | aaaaa |

| Quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com