Preparation method of low-temperature SCR denitration catalyst based on wolframite smelting slag

A technology of denitrification catalyst and wolframite, which is applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of high production cost of denitrification catalyst, high denitrification catalyst, complex process, etc. problems, to achieve high value-added resource utilization, excellent denitrification performance, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a low-temperature SCR denitration catalyst based on wolframite smelting slag, comprising the following steps:

[0031] (1) washing wolframite concentrate smelting slag with water to make it neutral, drying at 100°C for 12 hours to obtain dry material, grinding, and sieving through a 300-mesh sieve;

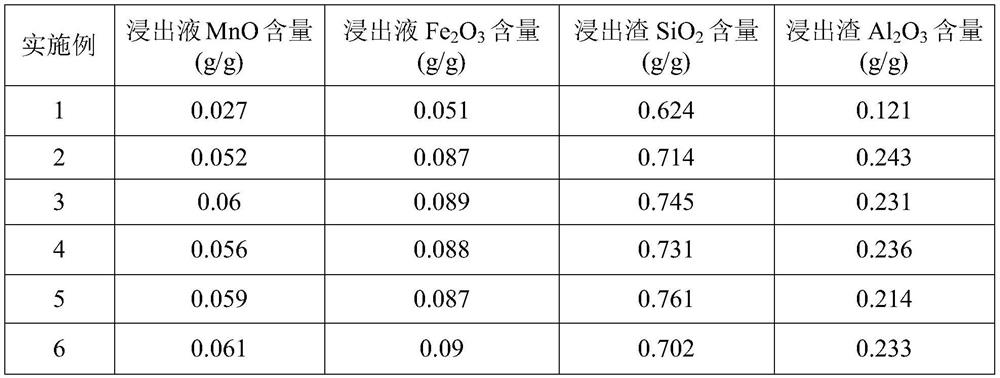

[0032] (2) Take 20 g of wolframite smelting slag powder obtained in step (1) and add it to 100 g of hydrochloric acid solution with a concentration of 25%, add 10 g of reducing agent sucrose, react and stir at 50 ° C for leaching for 4 hours, and filter to obtain supermanganese-rich , Fe filtrate A and silicon-aluminum-rich filter residue, iron oxide and manganese oxide contents in the leachate, and silicon-aluminum content in the leaching slag are shown in Table 1.

[0033] (3) Get 48g of the filtrate A prepared in step (2), add 1.6g of concentrated sulfuric acid dropwise to it, remove Ca 2+ , filtered to obtain filtrate B;

[0034] (4) Add ammonia...

Embodiment 2

[0038] A method for preparing a low-temperature SCR denitration catalyst based on wolframite smelting slag, comprising the following steps:

[0039] (1) washing wolframite concentrate smelting slag with water to make it neutral, drying at 100°C for 12 hours, grinding the dried material, and sieving through a 300-mesh sieve;

[0040] (2) Take 20g of wolframite smelting slag powder obtained in step (1) and add it to 100g of hydrochloric acid solution with a concentration of 25%, add 10g of reducing agent sucrose, react and stir at 30°C for leaching for 6h, and filter to obtain supermanganese-rich , Fe filtrate A and silicon-aluminum-rich filter residue, iron oxide and manganese oxide contents in the leachate, and silicon-aluminum content in the leaching slag are shown in Table 1.

[0041] (3) Get 48g of the filtrate A prepared in step (2), add 1.6g of concentrated sulfuric acid dropwise to it, remove Ca 2+ , filtered to obtain filtrate B;

[0042] (4) Add ammonia water to the ...

Embodiment 3

[0046] A method for preparing a low-temperature SCR denitration catalyst based on wolframite smelting slag, comprising the following steps:

[0047] (1) washing wolframite concentrate smelting slag with water to make it neutral, drying at 100°C for 12 hours to obtain dry material, grinding, and sieving through a 300-mesh sieve;

[0048] (2) Take 20g of wolframite smelting slag powder obtained in step (1) and add it to 100g of hydrochloric acid solution with a concentration of 25%, add 8g of reducing agent sucrose, react and stir at 50°C for leaching for 6h, and filter to obtain supermanganese-rich , Fe filtrate A and silicon-aluminum-rich filter residue, iron oxide and manganese oxide contents in the leachate, and silicon-aluminum content in the leaching slag are shown in Table 1.

[0049] (3) Get 48g of the filtrate A prepared in step (2), add 1.6g of concentrated sulfuric acid dropwise to it, remove Ca 2+ , filtered to obtain filtrate B;

[0050] (4) Add ammonia water to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com