Tungsten ore sorting method

A sorting and tungsten ore technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of high labor cost and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

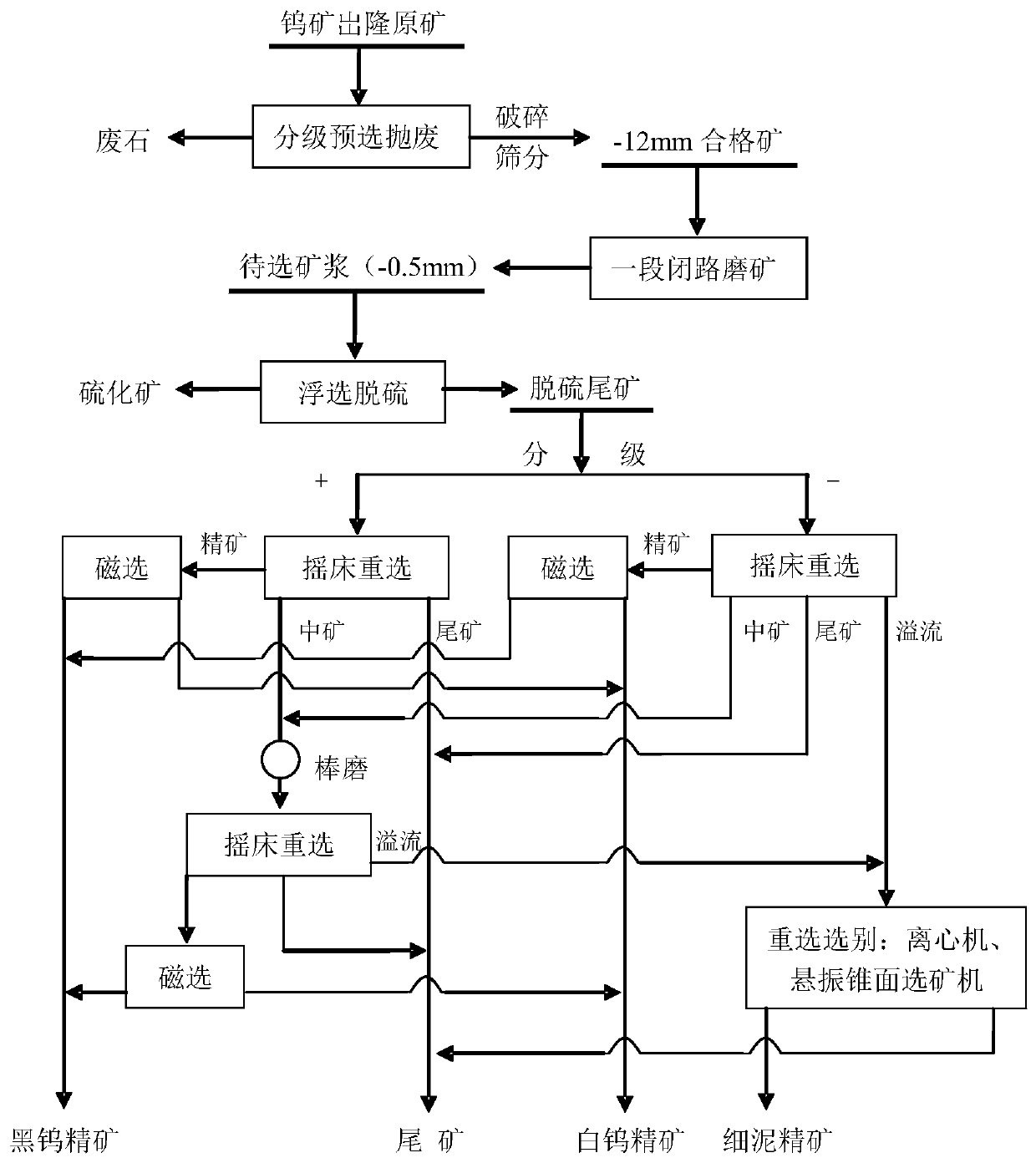

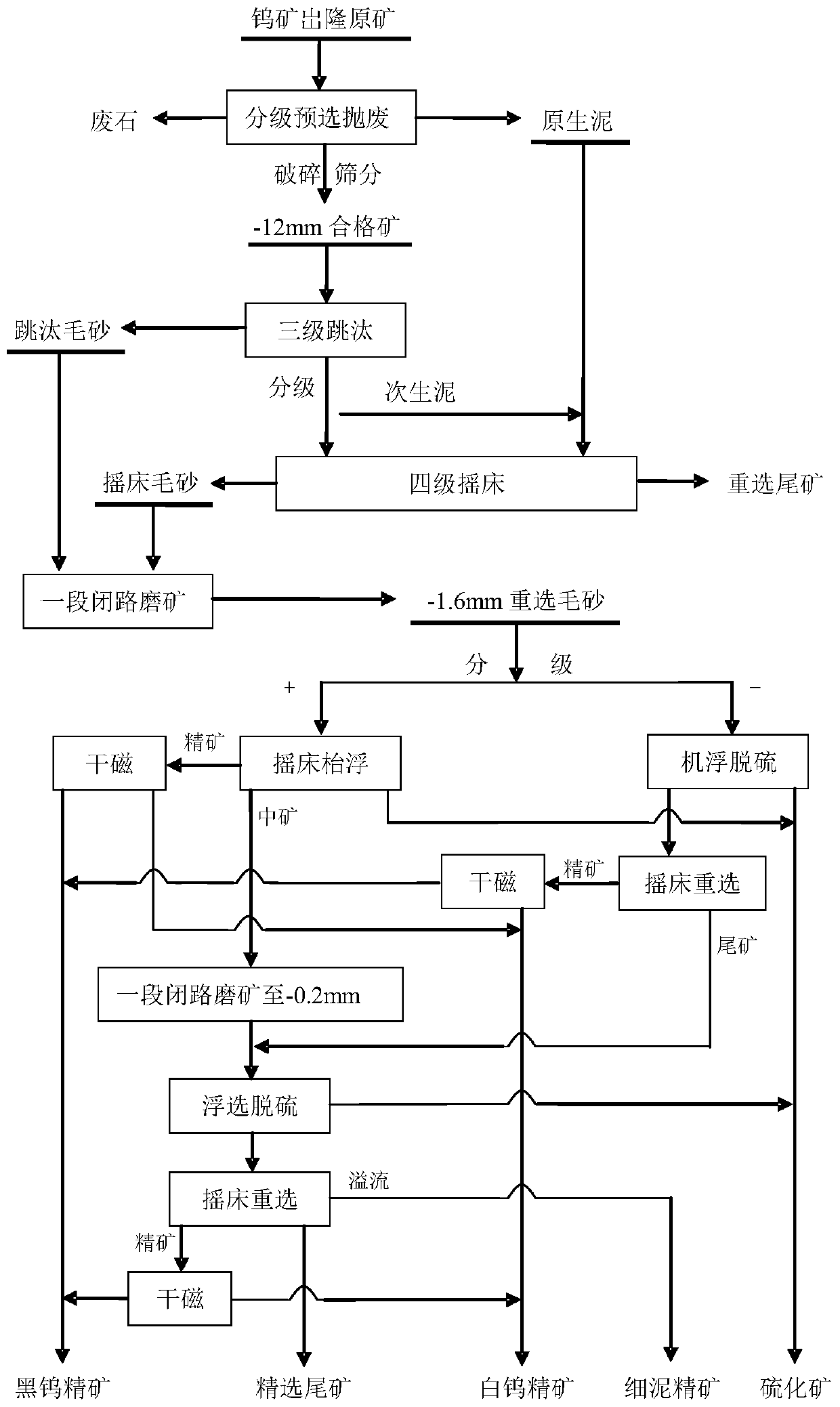

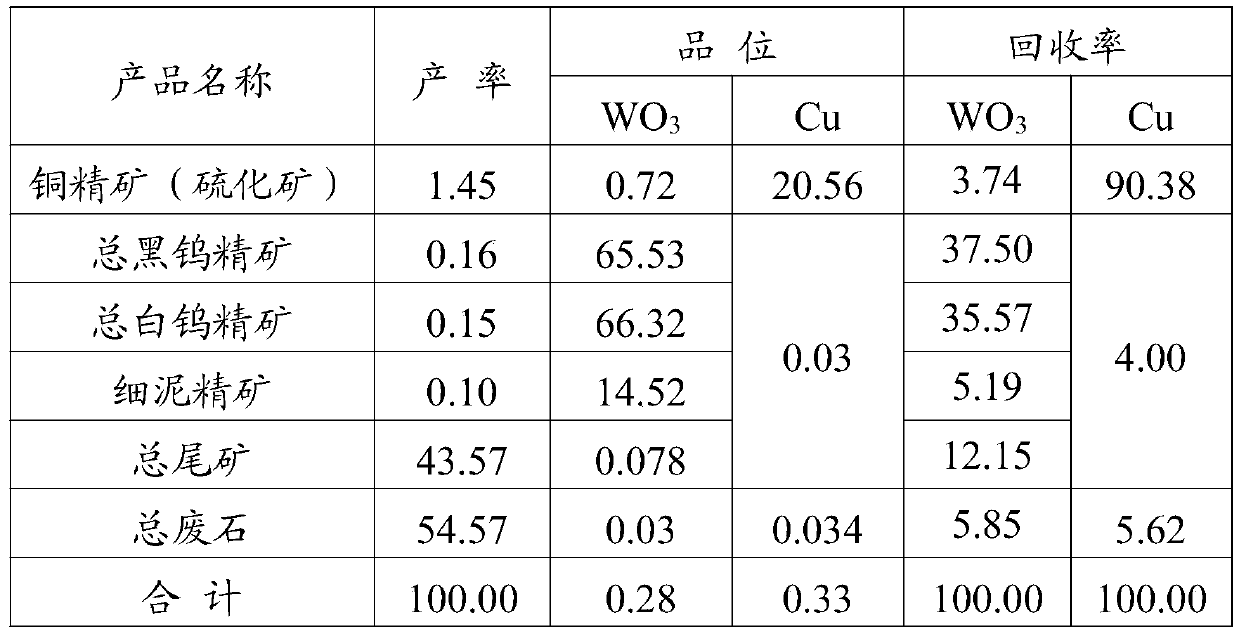

[0055] A copper and tungsten primary polymetallic symbiotic ore (black and white tungsten symbiotic ore) in Jiangxi, WO 3 The content of tungsten is 0.28%. Tungsten mainly exists in two forms of wolframite and scheelite. Wolframite accounts for about 54%, and scheelite accounts for about 42%. Other metal sulfides are mainly chalcopyrite, followed by magnetite Iron ore and pyrite; gangue minerals are mainly quartz, followed by feldspar, biotite and chlorite. according to figure 1 The flow chart shown is to sort the black and white tungsten paragenetic ore, including the following steps:

[0056] After the black and white tungsten symbiotic ore is excavated, the raw ore with a particle size of +120mm is hand-selected and discarded, and then manually hammered into the raw ore with a particle size of -120mm. After that, it is screened and classified into -120+50mm, -50+27mm , -27+16mm, -16+12mm and -12mm five grain grades, the raw ore of -120+50mm, -50+27mm and -27+16mm three gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com