Preselecting technology for extremely hungry hematite one-step classifying overflows through high gradient magnetic separator

A high-gradient magnetic separator, hematite technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increased sorting workload, reduced metal content, fine crystal particle size, etc., to achieve optimal The effects of sorting status, reducing consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

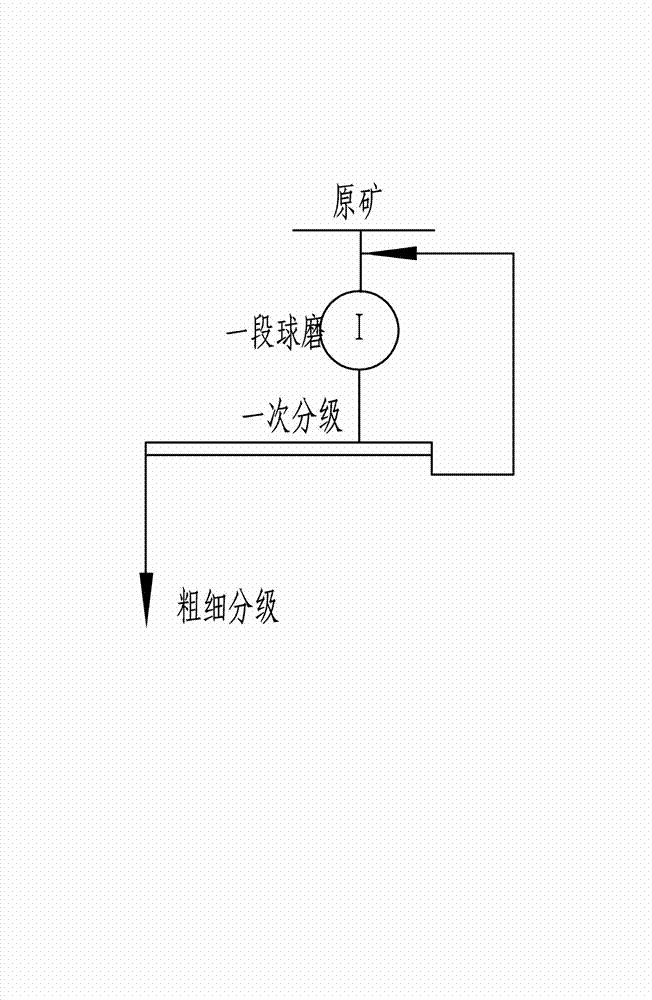

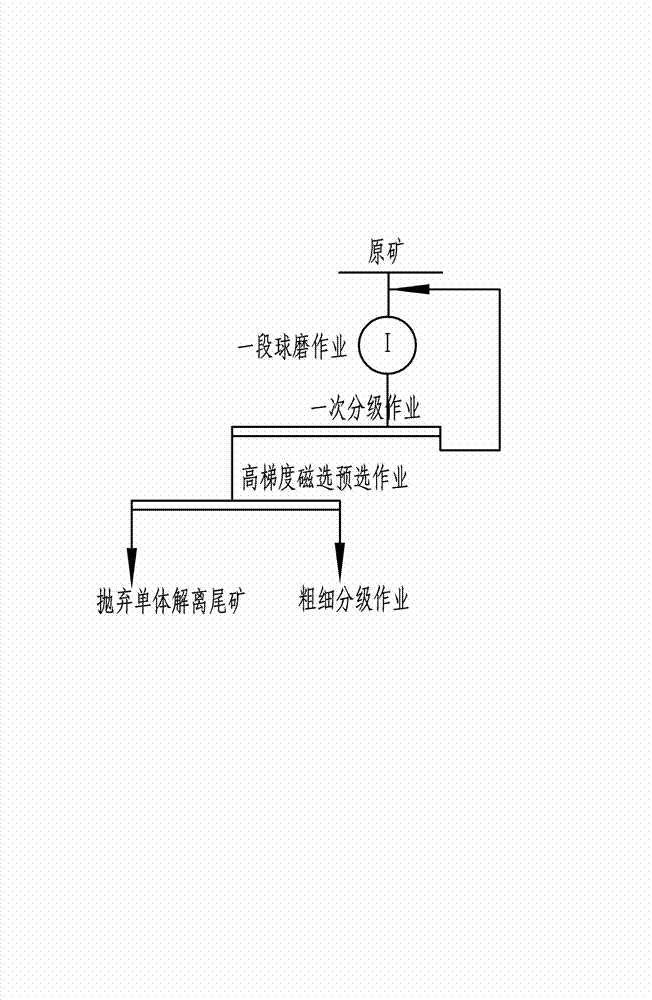

[0019] According to the present invention, the ultra-poor hematite primary classification overflow application high-gradient magnetic separator pre-selection process, including raw ore→one-stage grinding→secondary classification→coarse and fine classification, is characterized in that:

[0020] a) The cyclone overflow of a classification operation is fed into the high gradient magnetic separator operation, and the sand settling of a classification operation is returned to a grinding operation to form a closed-circuit grinding,

[0021] b) The concentrated ore from the high gradient magnetic separator operation is fed into the coarse and fine classification operation, and the monomer dissociated tailings from the high gradient magnetic separator operation are discarded.

[0022] The present invention uses a high-gradient magnetic separator to carry out efficient pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com