Scheelite beneficiation method

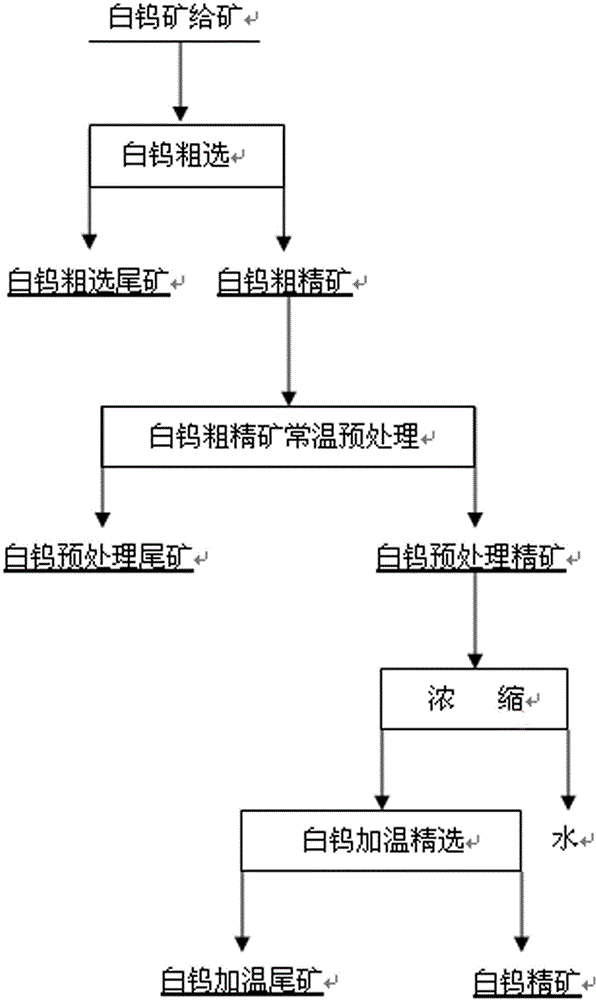

A mineral processing method and scheelite technology, applied in flotation, solid separation, etc., can solve the problems of large area of concentration equipment, unsuitable for large-scale application, and difficult separation, so as to reduce the amount of concentrated ore and heat the ore Quantity, conducive to large-scale production, and reduce the effect of subsidence area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

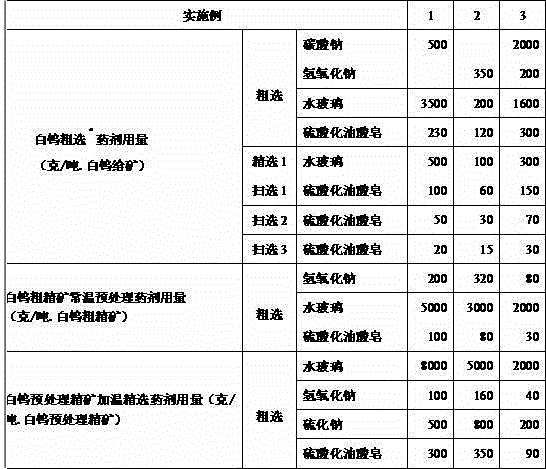

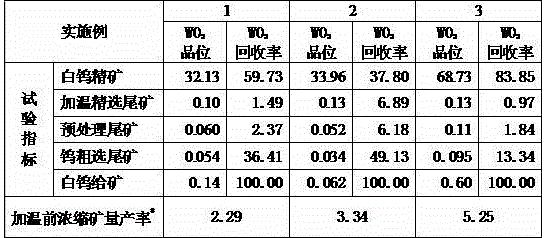

Embodiment 1

[0014] Scheelite feed contains WO 3 0.14%, CaCO 3 25.13%, CaF 2 7.8%, its scheelite is tungsten and molybdenum homogeneous scheelite (Ca[(W,Mo)O 4 ], scheelite pure mineral containing WO 3 42.15%).

[0015] 1) Rough selection of scheelite: ① first rough selection: add sodium carbonate, water glass and sulfated oleic acid soap according to the chemical system in Table 1, and stir for 15 minutes; Minutes; ③Third times of sweeping: add sulfated oleic acid soap according to the reagent system in Table 1, and stir for 10 minutes; obtain scheelite rough concentrate and scheelite roughing tailings;

[0016] 2) Pretreatment of rough scheelite concentrate at room temperature: ① 1 roughing: add sodium hydroxide, water glass and sulfated oleic acid soap to scheelite rough concentrate according to the chemical system in Table 1, and stir for 45 minutes; ② 3 times of washing : without adding chemicals, stirring for 5 minutes; ③Third times of sweeping: without adding chemicals, sti...

Embodiment 2

[0019] Scheelite feed contains WO 3 0.062%, CaCO 3 30.12%, CaF 2 16.16%, its scheelite is tungsten and molybdenum homogeneous scheelite (Ca[(W,Mo)O 4 ], scheelite pure mineral containing WO 3 40.15%).

[0020] 1) Rough selection of scheelite: ① 1st rough selection: add sodium hydroxide, water glass and sulfated oleic acid soap according to the chemical system in Table 1, and stir for 10 minutes; ②Third selection: add water glass according to the chemical system in Table 1, and stir 5 minutes; ③2 times of sweeping: add sulfated oleic acid soap according to the chemical system in Table 1, and stir for 5 minutes; obtain scheelite rough concentrate and scheelite roughing tailings;

[0021] 2) Pretreatment of rough scheelite concentrate at room temperature: ① 1 roughing: add sodium hydroxide, water glass and sulfated oleic acid soap to scheelite rough concentrate according to the chemical system in Table 1, and stir for 60 minutes; ② 3 times of washing : without adding che...

Embodiment 3

[0024] Scheelite feed contains WO 3 0.60%, CaCO 3 17.26%, CaF 2 30.30%, the scheelite pure mineral contains iron, and the scheelite pure mineral contains WO 3 73.05%.

[0025] 1) Rough selection of scheelite: ① 1st rough selection: add sodium carbonate, sodium hydroxide, water glass and sulfated oleic acid soap according to the chemical system in Table 1, and stir for 12 minutes; ②Second selection: add water according to the chemical system in Table 1 Glass, stirred for 2 minutes; ③Three times of sweeping: add sulfated oleic acid soap according to the chemical system in Table 1, and stir for 10 minutes; obtain scheelite rough concentrate and scheelite roughing tailings;

[0026] 2) Pretreatment of rough scheelite concentrate at room temperature: ① 1 roughing: add sodium hydroxide, water glass and sulfated oleic acid soap to scheelite rough concentrate according to the chemical system in Table 1, and stir for 30 minutes; ② 2 times of refining : without adding chemicals,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com