Dry pre-concentration process for weakly magnetic iron ore by size grading

An iron ore and weak magnetic technology, applied in the field of dry classification pre-selection process of weak magnetic iron ore, can solve the problem that weak magnetic iron ore cannot be pre-selection or the cost of pre-selection is high, so as to improve competitiveness, reduce costs, and achieve uniform particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Take 1 ton of 0~-80mm weak magnetic iron ore from Jiugang Jingtieshan, iron grade 32%, surrounding rock content 8%, iron ore specific gravity 4.2g / cm 3 , The specific gravity of the surrounding rock is 2.6g / cm 3 , do the following:

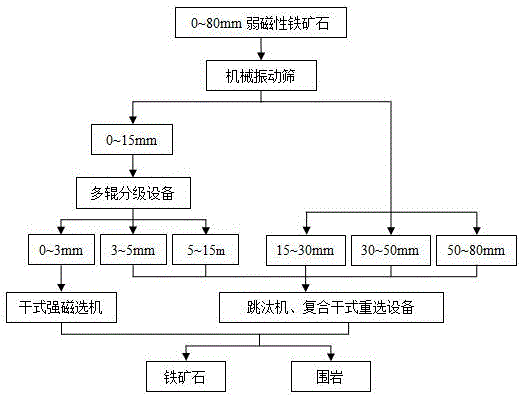

[0016] A. The weak magnetic iron ore is screened and classified by mechanical vibrating screen, and divided into 0~-15mm, +15~-30mm, +30~-50mm, +50~-80mm;

[0017] B. Use a multi-roller particle size classification device to classify ore with a particle size of 0~-15mm into 3 particle size ranges: 0~-3mm, +3~-10mm, and +10~-15mm;

[0018] C. The above-mentioned 0~-3mm size iron ore is pre-selected by dry strong magnetic separator, the magnetic field strength of magnetic separation is 8000 Oe, +3~-10mm, +10~-15mm, +15~-30mm, +30 ~-50mm, +50~-80mm iron ore particle size ranges are separated from the ore and surrounding rock by using composite dry gravity separation equipment, and the content of surrounding rock in each particle size iron or...

Embodiment 2

[0020] Take 1 ton of low-grade and weakly magnetic iron ore from Jingtieshan Huashugou V ore body in Jiugang, with iron grade of 22%, surrounding rock content of 15%, and iron ore specific gravity of 4.0g / cm 3 , The specific gravity of the surrounding rock is 2.5g / cm 3 , do the following:

[0021] A. The weak magnetic iron ore is screened and classified by mechanical vibrating screen, and divided into 0~-15mm, +15~-30mm, +30~-50mm, +50~-80mm;

[0022] B. Use a multi-roller particle size classification device to classify ore with a particle size of 0~-15mm into 3 particle size ranges: 0~-3mm, +3~-10mm, and +10~-15mm;

[0023] C. The above-mentioned 0~-3mm size iron ore is pre-selected by dry strong magnetic separator, the magnetic field strength of magnetic separation is 9000 Oe, +3~-10mm, +10~-15mm, +15~-30mm, +30 ~-50mm, +50~-80mm iron ore particle size ranges are separated from the ore and surrounding rock by using composite dry gravity separation equipment, and the conten...

Embodiment 3

[0025] Take 1 ton of JISCO Sidaogou weak magnetic iron ore, the iron grade is 26%, the surrounding rock content is 13%, and the iron ore specific gravity is 3.6g / cm 3 , The specific gravity of the surrounding rock is 2.1g / cm 3 , do the following:

[0026] A. The weak magnetic iron ore is screened and classified by mechanical vibrating screen, and divided into 0~-15mm, +15~-30mm, +30~-50mm, +50~-80mm;

[0027] B. Use a multi-roller particle size classification device to classify ore with a particle size of 0~-15mm into 3 particle size ranges: 0~-3mm, +3~-10mm, and +10~-15mm;

[0028] C. The above-mentioned 0~-3mm size iron ore is pre-selected by dry strong magnetic separator, the magnetic field strength of magnetic separation is 10000 Oe, +3~-10mm, +10~-15mm, +15~-30mm, +30 ~-50mm, +50~-80mm iron ore particle size ranges are separated from the ore and surrounding rocks by composite dry gravity separation equipment, and the content of surrounding rocks in each particle size ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com