Beneficiation method for ultrafine fraction cassiterite

A beneficiation method and fine particle technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of low recovery rate, high production cost, low grade, etc., and achieve enhanced recovery, improved recovery, and enhanced hydrophobicity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

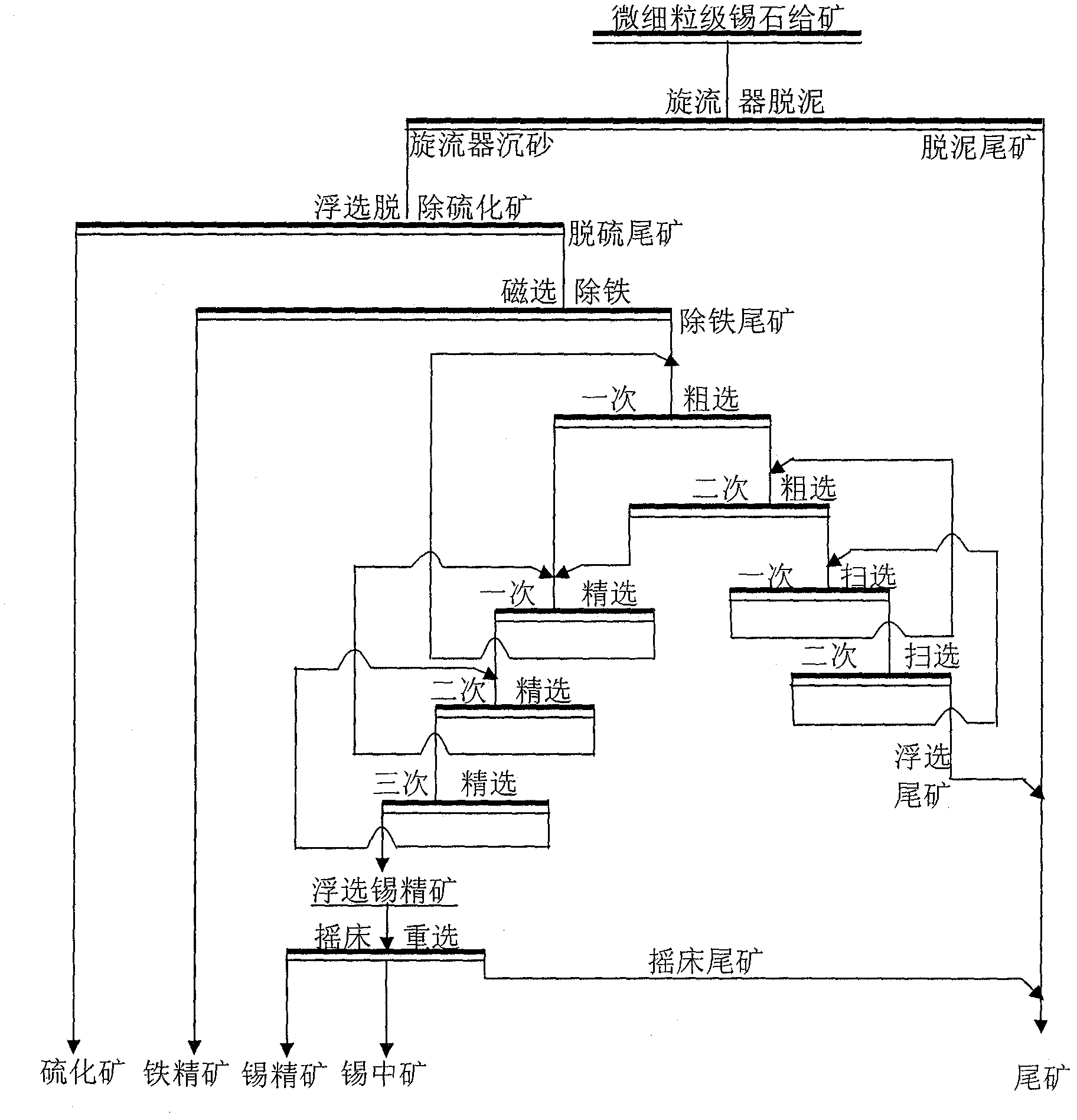

Image

Examples

Embodiment 1

[0027] The ore feed is cassiterite polymetallic sulfide ore in a certain place in Yunnan, China. After grading by FX200 cyclone, the tin grade of -0.043mm particle size is 0.963%.

[0028] The FX75 cyclone is used for desliming operation, and the desliming tailings with a yield of 26.12% and the cyclone grit are obtained; after the cyclone is gritted, water is added to adjust the slurry to a pulp concentration of 26%, and the weight of the ore is added. Collecting agent xanthate 300g / t, foaming agent No. 2 oil 30g / t, remove sulfide ore operation, obtain sulfide ore and desulfurization tailings with a yield of 4.67%; 0.15T to obtain iron concentrate and iron-removing tailings with a yield of 12.88% and a grade of 60.57%. Concentrate the iron-removing tailings to a pulp concentration of 24%, add the regulator sodium carbonate 200g / t, and stir for 2 minutes; sodium hexametaphosphate 100g / t, stirring for 2 minutes; auxiliary collector tributyl phosphate 80g / t, stirring for 10 minu...

Embodiment 2

[0030] The ore feed is the beneficiation tailings of a tin-containing polymetallic sulfide ore in Yunxi, the tin grade is 0.71%, the -0.043mm particle size accounts for 71%, and the tin occupation rate reaches 91%.

[0031]The desliming operation adopts FX125 cyclone to obtain deslimed tailings and cyclone sand settling with a yield of 19.76%;

[0032] Add water to the hydrocyclone to adjust the slurry to a pulp concentration of 25%, add collector butyl xanthate 200g / t, foaming agent No. 2 oil 50g / t, and remove sulfide ore according to the weight of ore feed. Sulfide ore and desulfurized tailings with a yield of 2.97%; the desulfurized tailings are subjected to magnetic separation to remove iron, and the magnetic field strength is 0.3T to obtain iron concentrates and iron-removed tailings with a yield of 5.97% and a grade of 56.71%. After concentrating and adjusting the slurry to a pulp concentration of 27%, add the regulator sodium carbonate 350g / t and stir for 3 minutes; car...

Embodiment 3

[0034] The ore feed is the old tailings of a tin concentrator in Guangxi, China. The tin grade is 1.13%, the -0.043mm particle size accounts for 57%, and the tin share is 72%.

[0035] The FX100 cyclone is used for desliming operation, and the desilting tailings with a yield of 15.76% and the cyclone grit are obtained; after the cyclone grit is added with water to adjust the pulp concentration to 22%, according to the weight of the ore, add the catch Collecting agent xanthate 300g / t, foaming agent No. 2 oil 40g / t, carry out sulfide ore removal operation, obtain sulfide ore and desulfurization tailings with a yield of 2.97%; desulfurization tailings are subjected to magnetic separation and iron removal operations, magnetic Strength 0.2T, yield 7.97%, grade 61.65% iron concentrate and iron-removing tailings; iron-removing tailings are concentrated and adjusted to a pulp concentration of 23%, add regulator sodium carbonate 400g / t, and stir for 3 minutes ; sodium hexametaphosphate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com