Zinc-sulfur separation and beneficiation method of pyrrhotite-rich zinc sulfide ore

A technology of pyrrhotite and ore dressing methods, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of difficult separation and inability to achieve effective separation of zinc and sulfur, so as to reduce environmental pollution and save the amount of chemicals , The effect of reducing the amount of ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

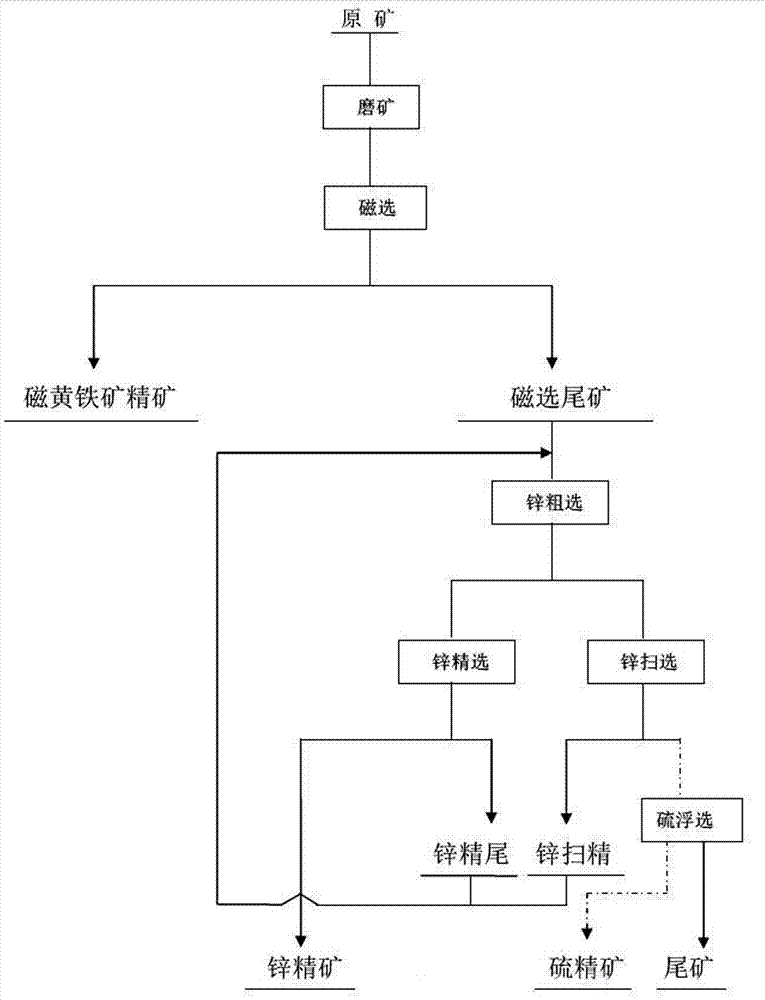

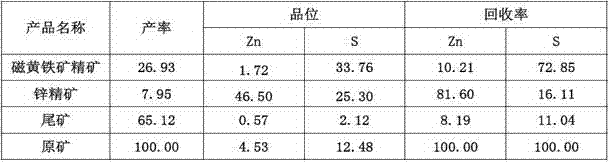

[0020] The test ore is zinc-sulfur ore from a certain place in Fujian. The zinc-sulfur ore contains 1.25% zinc and 15.47% sulfur, of which sulfur in pyrrhotite accounts for 75% of the total sulfur. The technological process of separating pyrrhotite by weak magnetic separation—and then flotation zinc, the technical indicators obtained are shown in Table 1. The main technical parameters are: the grinding fineness is -0.075mm, accounting for 65%, the magnetic field strength is 1250 Gs, the pyrrhotite is firstly selected to obtain the magnetic sulfur concentrate, and the tailings of the magnetic separation are flotation through the process of first roughing, second sweeping and second refining zinc. Flotation process parameters are: roughing conditions: 1000 grams of lime, adjust the pH value of the slurry to 12, activator CuSO 4 100 grams, collector butyl xanthate 50 grams, foaming agent 2 # 20 grams of oil; the amount of various agents added in one sweep is: 500 grams of lime...

Embodiment 2

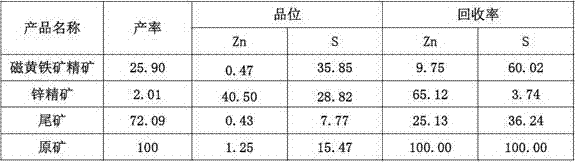

[0024] The test ore is a copper-zinc-sulfur ore in Mongolia. The tailings after copper flotation were used as test ore. The grade of zinc in the test sample is 4.53%, and the sulfur content is 12.48%, of which the sulfur in pyrrhotite accounts for 90%. Using weak magnetic separation to select pyrrhotite-re-flotation zinc process, the technical indicators obtained are shown in Table 2. The main technical parameters are: the magnetic field strength is 1200 Gs to first select pyrrhotite, and the tailings of magnetic separation are flotation zinc through the process of first roughing, second sweeping and second refining. Flotation process parameters are: roughing conditions: 1000 grams of lime, adjust the pH value of the slurry to 11.5, activator CuSO 4 100 grams, collector butyl xanthate 50 grams, foaming agent 2 # 20 grams of oil; the amount of various agents added in one sweep is: 500 grams of lime, CuSO 4 50 grams, butyl xanthate 25 grams, 2 # 10 grams of oil; the additio...

Embodiment 3

[0028] The test ore is a zinc-sulfur ore in Inner Mongolia. The zinc-sulfur ore contains 2.81% zinc and 20.90% sulfur. From the perspective of ore mineral composition, the main mineral is pyrrhotite, which accounts for 60.03% of the mineral content; followed by pyrite, which accounts for 10% of the mineral content. 5.46%; sphalerite accounts for 5.21% of the mineral volume. Using the technological process of magnetic separation of pyrrhotite - flotation of zinc - further flotation of sulfur, the technical indicators obtained are shown in Table 3. The main technical parameters are: the grinding fineness is -0.075mm, accounting for 70%, the magnetic field strength is 1100 Gs, the pyrrhotite concentrate is firstly selected, and the tailings of the magnetic separation are subjected to the flotation process of one rough, one sweep and two fine. Flotation process parameters are: roughing conditions: 1000 grams of lime, adjust the pH value of the pulp to 13, activator CuSO 4 120 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com