Beneficiation method of low-grade tungsten ore

A beneficiation method and low-grade technology, applied in the direction of chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as difficult to achieve large-scale, long process, difficult production operation, etc. The effect of taste and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

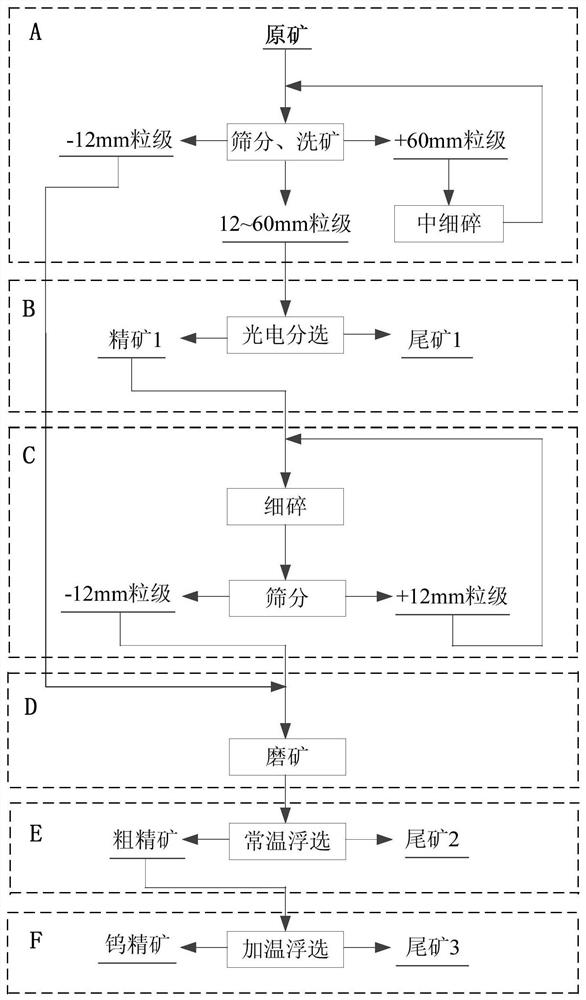

Method used

Image

Examples

Embodiment 1

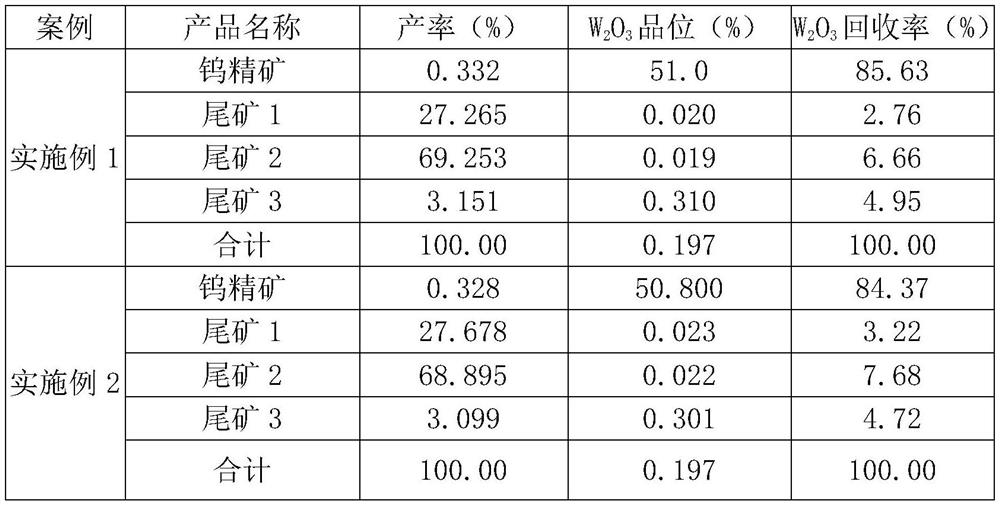

[0033] The raw ore is coarsely crushed to below -80mm, screened by a double-layer original vibrating sieve, and the +60mm particle size is crushed by a medium and fine crushing cone, and then returned to the original vibrating sieve for screening, -12mm particle size enters the grinding, and the 12-60mm particle size enters the photoelectric select. The 12-60mm particle size enters the photoelectric separation for pre-throwing tailings, and the photoelectric separation machine can get the disposable tailings 1 with a yield of 27.265%, W 2 o 3 Grade 0.02%, Concentrate 1 Medium W 2 o 3 The content is increased to 0.403%; the concentrate 1 is crushed to a particle size below -12mm through the fine crushing-screening closed-circuit process; the particle size below -12mm obtained by coarse crushing-screening and the particle size below -12mm obtained by photoelectric separation concentrate 1 After the two parts of ore are combined, they are fed into the ball mill. The ore and wa...

Embodiment 2

[0035] The raw ore is coarsely crushed to below -80mm, screened by a double-layer original vibrating sieve, and the +60mm particle size is crushed by a medium and fine crushing cone, and then returned to the original vibrating sieve for screening, -12mm particle size enters the grinding, and the 12-60mm particle size enters the photoelectric select. The 12-60mm particle size enters the photoelectric separation for pre-throwing tailings, and the photoelectric separation machine obtains the discardable tailings 1. The yield rate is 27.678%, W 2 o 3 Grade 0.023%, Concentrate 1 Medium W 2 o 3The content is increased to 0.4%; the concentrate 1 is crushed to a particle size below -12mm through the fine crushing-screening closed-circuit process; the particle size below -12mm obtained by coarse crushing-screening and the particle size below -12mm obtained by photoelectric separation concentrate 1 After the two parts of ore are combined, they are fed into the ball mill, and the ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com