Flotation method for lead and zinc sulfide ores

A lead-zinc sulfide, flotation technology, applied in flotation, solid separation and other directions, can solve the problems of expensive chemicals, low flotation rate and high cost, and achieve the effect of reducing the types of use, reducing costs and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

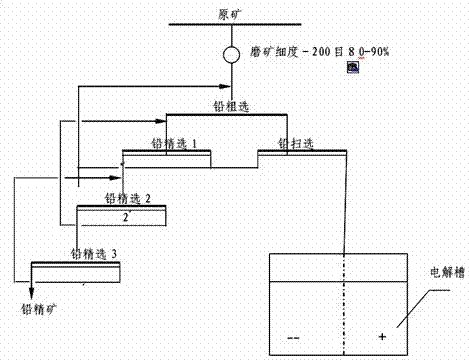

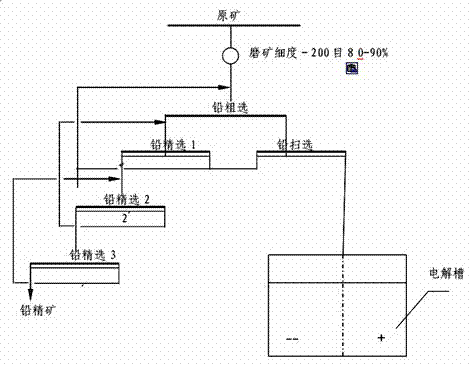

Image

Examples

Embodiment 1

[0024] Embodiment 1: the flotation method of this lead-zinc sulfide ore, concrete operation is as follows:

[0025] Using the raw ore of a lead-zinc sulfide mine in Yunnan containing 5.82% Pb and 6.5% Zn, the lead-zinc sulfide ore is crushed using a three-stage and one-closed-circuit crushing process. The crushing particle size is -15mm, and then two-stage closed-circuit grinding is performed. The particle size is -200 mesh, accounting for 80%, the concentration of lead-zinc ore flotation mass percentage after grinding is 21%, and a mixed inhibitor of 100g / t of collector ethoxide nitrogen, 400g / t of zinc sulfate and 400g / t of sodium sulfite is added , foaming agent 730A 60g / t, lime 1000g / t, adjust the pH to 11, and carry out lead flotation. After one roughing, one sweeping and three times of beneficiation, lead concentrate is obtained. The grade of lead concentrate is 55.6%. The rate is 84.87%; the tailings after lead roughing are added with 200g / t of activator ammonium sulfit...

Embodiment 2

[0026] Embodiment 2: the flotation method of this lead-zinc sulfide ore, concrete operation is as follows:

[0027] Using the raw ore of a lead-zinc mine in Yunnan containing 5.82% Pb and 6.5% Zn, the lead-zinc sulfide ore is crushed by a three-stage and one-closed-circuit crushing process. The crushing particle size is -10mm, and then two-stage closed-circuit grinding is performed. The grinding particle size -200 mesh accounts for 90%, the flotation mass percentage concentration of lead-zinc sulfide ore after grinding is 25%, adding collector 20g / t ethyl disulfide nitrogen, zinc sulfate 100g / t and sodium sulfite 100g / t mixed inhibitor, starting Foaming agent 730A 20g / t, lime 200g / t, adjust PH to 11.5, carry out lead flotation, get lead concentrate after one roughing, one sweeping and three times beneficiation, the lead concentrate grade is 56.01%, the recovery rate is 84.56%; Add 150g / t of activator ammonium sulfite, 200g / t of butyl xanthate, 45g / t of foaming agent 730A to th...

Embodiment 3

[0028] Embodiment 3: the flotation method of this lead-zinc sulfide ore, concrete operation is as follows:

[0029] Using the raw ore of a lead-zinc mine in Yunnan containing 5.82% Pb and 6.5% Zn, the lead-zinc sulfide ore is crushed with a three-stage and one-closed circuit crushing process. The crushing particle size is -20mm, and then two-stage closed-circuit grinding is carried out. The grinding particle size -200 mesh accounts for 85%, the flotation mass percentage concentration of lead-zinc sulfide ore after grinding is 28%, adding collector 80g / t of ethyl disulfide nitrogen, 200g / t of zinc sulfate and 300g / t of sodium sulfite mixed inhibitors, starting Foaming agent 730A 70g / t, lime 600g / t, adjust PH to 12, carry out lead flotation, after one roughing, one sweeping and three times of beneficiation, lead concentrate is obtained, the grade of lead concentrate is 55.6%, and the recovery rate is 84.87%; Add 100g / t of activator ammonium sulfite, 300g / t of butyl xanthate, 50g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com