Smelting method and device for molten oxidized lead slag

A smelting method and lead oxide technology, applied in the field of high-efficiency lead reduction, can solve the problems of long feeding time, erosion and damage of copper water jacket, large amount of flue gas in the smelting process, low production cost and investment cost, and elimination of erosion and damage. Hidden dangers and the effect of compact smelting workshop layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

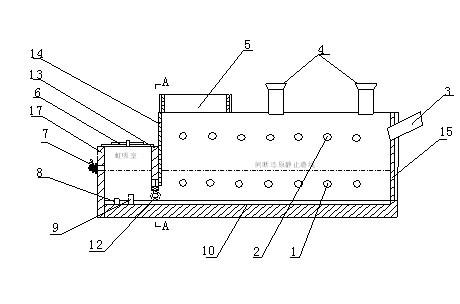

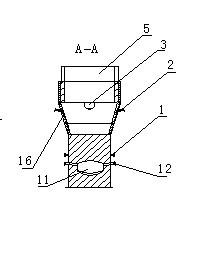

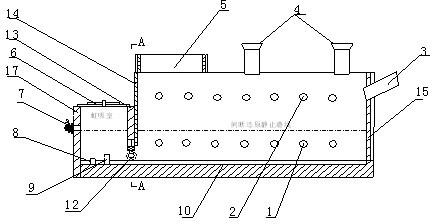

Image

Examples

Embodiment 1

[0041] The high-lead slag obtained from the oxidation smelting of the lead concentrate molten pool has a temperature of 1020°C, and its main chemical composition is shown in Table 1.

[0042] Table 1 Main chemical components of high-lead slag, mass percentage (%)

[0043] ingredients Pb Zn Cu SiO 2 Fe CaO S content 46.54 9.53 1.00 7.68 12.59 5.59 0.73

[0044] Coal particles, particle size is 20~30mm, fixed carbon content is 70.3%; limestone particle size is 5~10mm, CaCO 3 Content 92.58%, industrial oxygen, the volume percent concentration of oxygen ≥ 99%. The molten high-lead slag of the above composition flows from the molten pool oxidation smelting furnace through the chute into the molten pool reduction smelting furnace, and the limestone and coal particles of the above composition are added to the upper feeding port of the reduction furnace. The amount of limestone added is 7.35% of the high lead slag mass. In the initial reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com