Method for preparing polyferric chloride flocculant by using steel wire rope sludge and waste salt

A technique of polymerizing ferric chloride and flocculant, which is applied in ferric halide, flocculation/precipitation water/sewage treatment, etc., and can solve the problems of unrealized harmless treatment and resource utilization of steel wire rope pickling sludge and waste hydrochloric acid. To achieve the effect of excellent purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

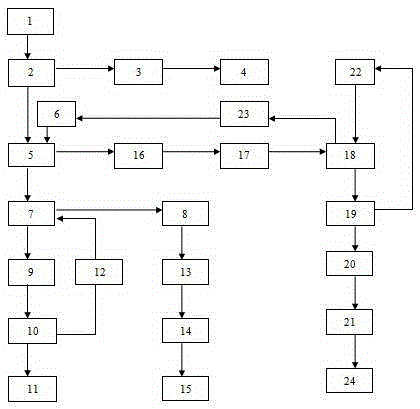

[0028] see figure 1, put 2000L waste hydrochloric acid (the mass concentration of hydrochloric acid is 13%, the mass concentration of lead ion is 1620ppm, the mass concentration of iron ion is 9.7%) into the extraction reaction tank 2, add 1000kg steel wire rope pickling sludge (moisture content 76.8% , the mass concentration of iron ions is 10.8%, and the mass concentration of lead ions is 2000ppm) 1, stirring and reacting for 30 minutes, after removing the sludge residue 4 through the plate and frame filter press 3, the filtrate enters the deleading reaction tank 5, gradually drops Add 260L mass concentration of 17% sodium sulfide solution 6, continue to stir and react for 30 minutes after the dropwise addition is completed, discharge to the static sedimentation tank 7, leave it for 2 hours, then pump the supernatant into the ferric chloride solution storage tank 8. The bottom sludge 9 of the sedimentation tank is filtered through the plate and frame filter press 10 to obtai...

Embodiment 2

[0032] see figure 1 , put 2000L waste hydrochloric acid (the mass concentration of hydrochloric acid is 5%, the mass concentration of lead ion is 320ppm, the mass concentration of iron ion is 9%) into the extraction reaction tank 2, add 1000kg steel wire rope pickling sludge (moisture content 80% , the mass concentration of iron ions is 11.5%, the mass concentration of lead ions is 2300ppm) 1, stirring reaction for 50 minutes, after the plate and frame filter press 3 removes the sludge residue 4, the filtrate enters the deleading reaction tank 5, gradually drops Add 230 L of potassium sulfide solution 6 with a mass concentration of 10%, continue to stir and react for 45 minutes after the addition is complete, discharge the material to the static precipitation tank 7, and leave it for 3 hours, then pump the supernatant into the ferric chloride solution storage tank 8. The bottom sludge 9 of the sedimentation tank is filtered by a plate and frame filter press 10 to obtain a lead...

Embodiment 3

[0035] Example 3: Example of use

[0036] The polyferric chloride flocculant prepared in Example 1 was used for domestic sewage treatment. at 1m 3 Add 1.5kg of polyferric chloride flocculant to the domestic sewage, stir for 5 minutes, let it settle for 30 minutes, and take samples to test the treatment effect of domestic sewage. Before treatment, domestic sewage turbidity 240.6NTU, COD Cr 656.6mg / L, ammonia nitrogen 30.9mg / L, total phosphorus 3.6mg / L, after treatment, turbidity decreased by 97%, COD Cr , ammonia nitrogen and total phosphorus removal rates were 79.5%, 81.2% and 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com