Catalytic converter

A catalytic converter and catalyst layer technology, applied in the direction of catalyst carrier, chemical instrument and method, catalyst activation/preparation, etc., can solve the problems of high exhaust gas purification performance, which is difficult to expect, and achieve high hydrogen sulfide suppression effect and good exhaust gas purification performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

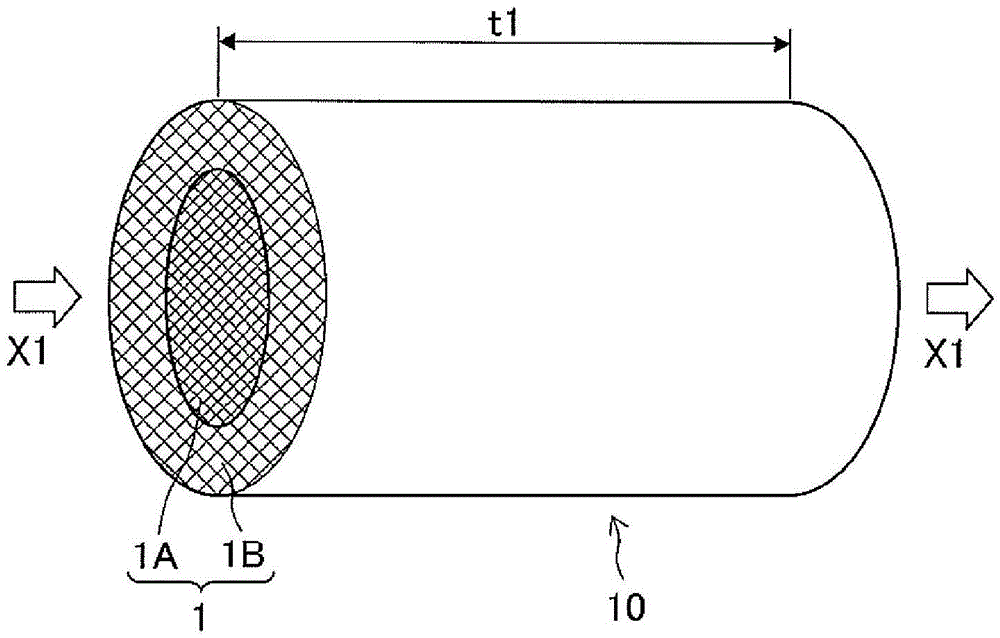

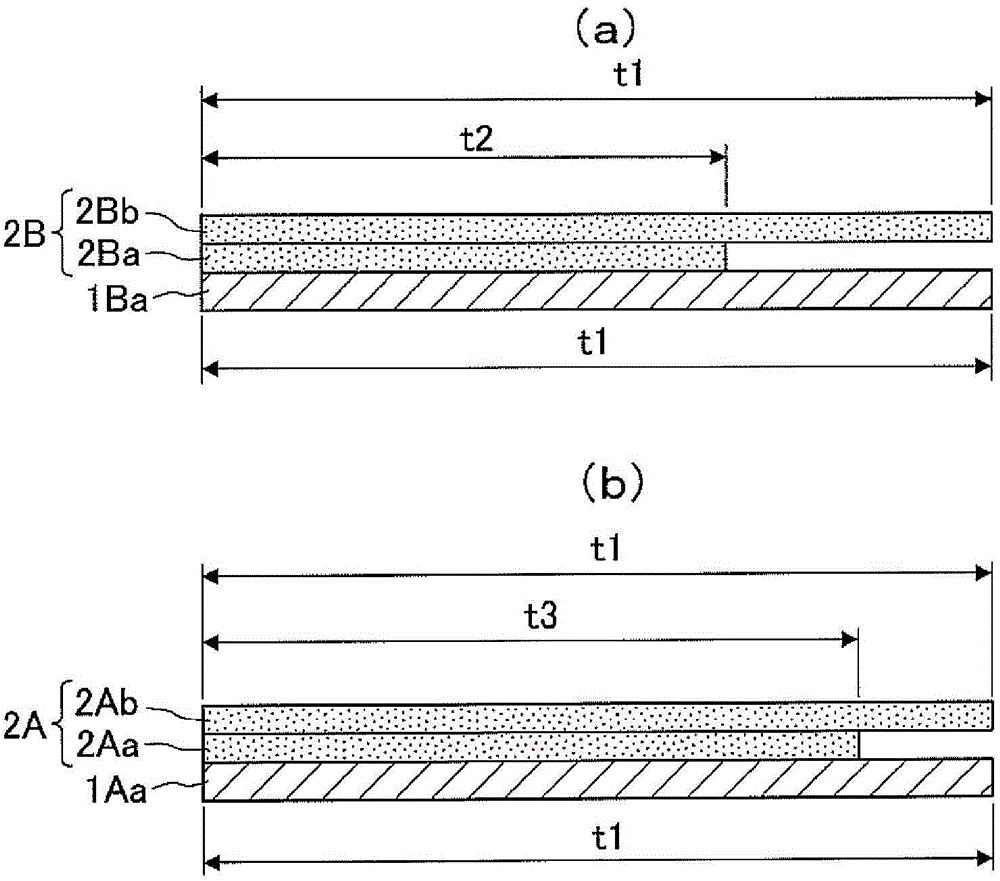

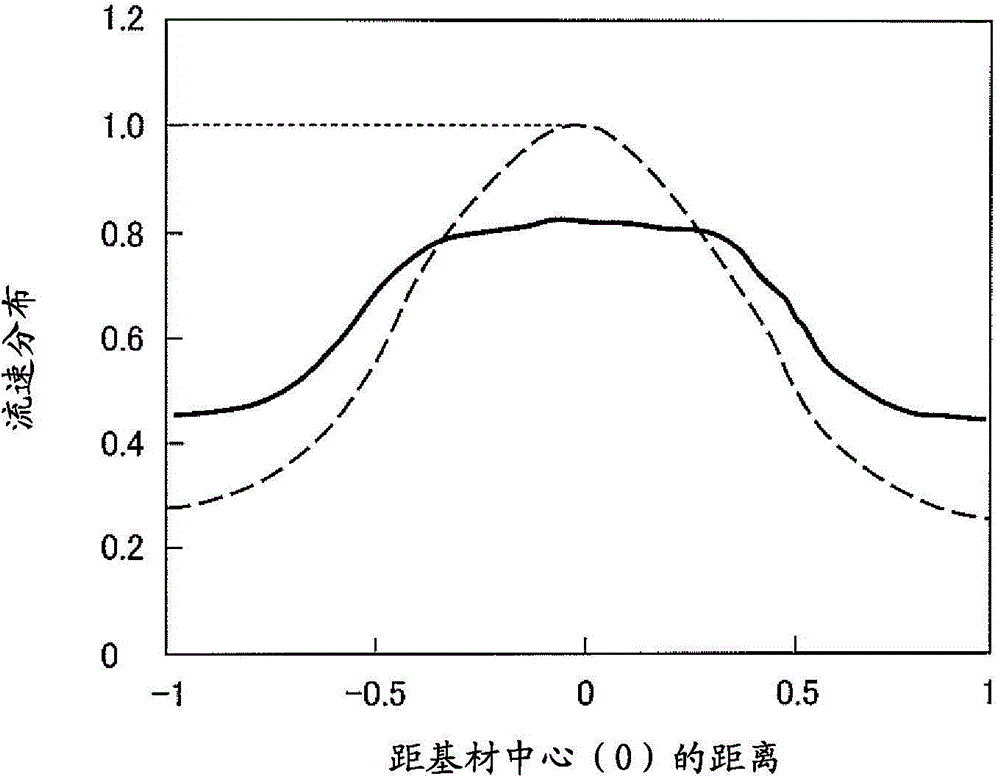

Embodiment 1

[0051] A honeycomb structure substrate made of cordierite was produced by extrusion molding, so that the cell density of the central area and the peripheral area were different. The size of the honeycomb structure is that the diameter of the circular section perpendicular to the flow direction of the exhaust gas is Ф103 mm, the length t1 in the longitudinal direction is 105 mm, and the cell density in the peripheral area with a relatively low cell density is 400 cpsi (62 cells / cm 2 ), the cell density in the central region with a relatively high cell density is 600cpsi (93 cells / cm 2 ), the boundary line between the central area and the peripheral area is at the position of Ф70mm, and the lattice shape of the chamber is quadrangular. Moreover, the catalyst layer has a double-layer structure, the lower layer is a layer carrying Pt, and the loading amount is 0.7 g / L, and the upper layer is a layer carrying Rh, and the loading amount is 0.2 g / L. Regarding the length of the cataly...

Embodiment 2

[0053] The length of the catalyst layer was the same as in Example 1 except that the length of the lower layer in the peripheral region was 60% of the length of the substrate.

Embodiment 3

[0055] Regarding the length of the catalyst layer, the length of the lower layer in the peripheral region was 80% of the length of the substrate (therefore, the length of the lower layer of the catalyst layer in the peripheral region was the same as that in the central region), and it was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com