Biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings, and preparation method thereof

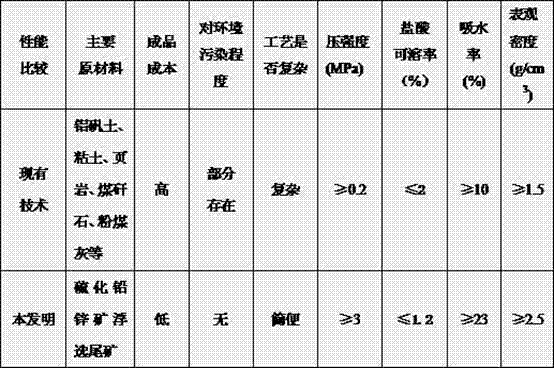

A technology for flotation tailings and lead-zinc sulfide, which is applied to the removal of ceramic products, other household utensils, and solid waste. It can solve the problems of fragility and cracking, incomplete combination of treatment effect and economic performance, and low strength of finished products. , to achieve the effect of high degree of industrialization, high quality and low price of finished products, and reduced cost of main materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

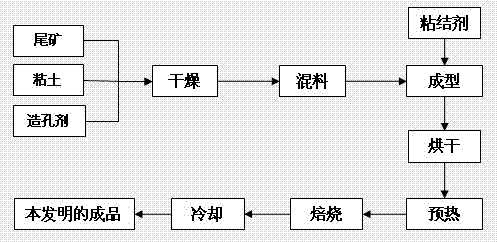

[0029] combine figure 1, a kind of preparation method that utilizes lead-zinc ore flotation tailings biological ceramsite filter material that the present invention proposes, is to be by initial main and auxiliary raw material according to the lead-zinc ore flotation tailings biological ceramsite filter material of the present invention After the proportioning and weighing, through the steps of drying→mixing→forming→drying→preheating→roasting→cooling, the finished bio-ceramic filter material of lead-zinc sulfide ore flotation tailings is obtained, specifically including:

[0030] Step 1, drying: drying the weighed and proportioned lead-zinc ore flotation tailings main material, clay, and pore-forming agent auxiliary materials at 100-110°C for later use;

[0031] Step 2, mixing materials: mix the flotation tailings, clay and pore-forming agent main and auxiliary materials that are dried and used in step 1, and then sprinkle them in the disc granulator for later use;

[0032] ...

Embodiment 1

[0038] Embodiment 1: biological ceramsite filter material of the present invention is made of 85.8wt.% lead-zinc ore flotation tailings, 12.2wt.% clay, 2wt.% sawdust pore-forming agent and lignin xanthogen with an additional mass fraction of 10% It is made of calcium acid solution binder, and the solid-liquid ratio of the raw materials used in the biological ceramsite filter material is 10:1. The preparation method of biological ceramsite filter material finished product of the present invention specifically comprises:

[0039] Step 1, drying: drying the weighed and proportioned lead-zinc ore flotation tailings main material, clay, and pore-forming agent auxiliary materials at 105°C for later use;

[0040] Step 2, mixing materials: Mix the flotation tailings, clay and pore-forming agent main and auxiliary materials of the lead-zinc sulfide ore flotation tailings, clay and pore-forming agent that are dried and used in step 1, and then sprinkle them in a Φ80mm disc granulator f...

Embodiment 2

[0046] Embodiment 2: biological ceramsite filter material of the present invention is made of 80wt.% lead-zinc ore flotation tailings, 18.5wt.% clay, 1.5wt.% sawdust pore-forming agent and sodium silicate solution with an additional mass fraction of 10% It is made of binder, and the solid-to-liquid ratio of the raw materials used in the biological ceramsite filter material is 8:1. The preparation method of biological ceramsite filter material finished product of the present invention specifically comprises:

[0047] Step 1, drying: drying the weighed and proportioned lead-zinc ore flotation tailings main material, clay, and pore-forming agent auxiliary materials at 100°C for later use;

[0048] Step 2, mixing materials: Mix the flotation tailings, clay and pore-forming agent main and auxiliary materials of the lead-zinc sulfide ore flotation tailings, clay and pore-forming agent that are dried and used in step 1, and then sprinkle them in a Φ80mm disc granulator for later use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com