Process of preparing sodium cyanide and lead sulfide for gold ore sorting from waste sodium cyaide desulfurizing dreg

A technology for selecting sodium gold cyanide and desulfurization waste residue is applied in the field of preparing and selecting sodium gold cyanide and lead sulfide from sodium cyanide desulfurization waste residue. The effect of high output and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

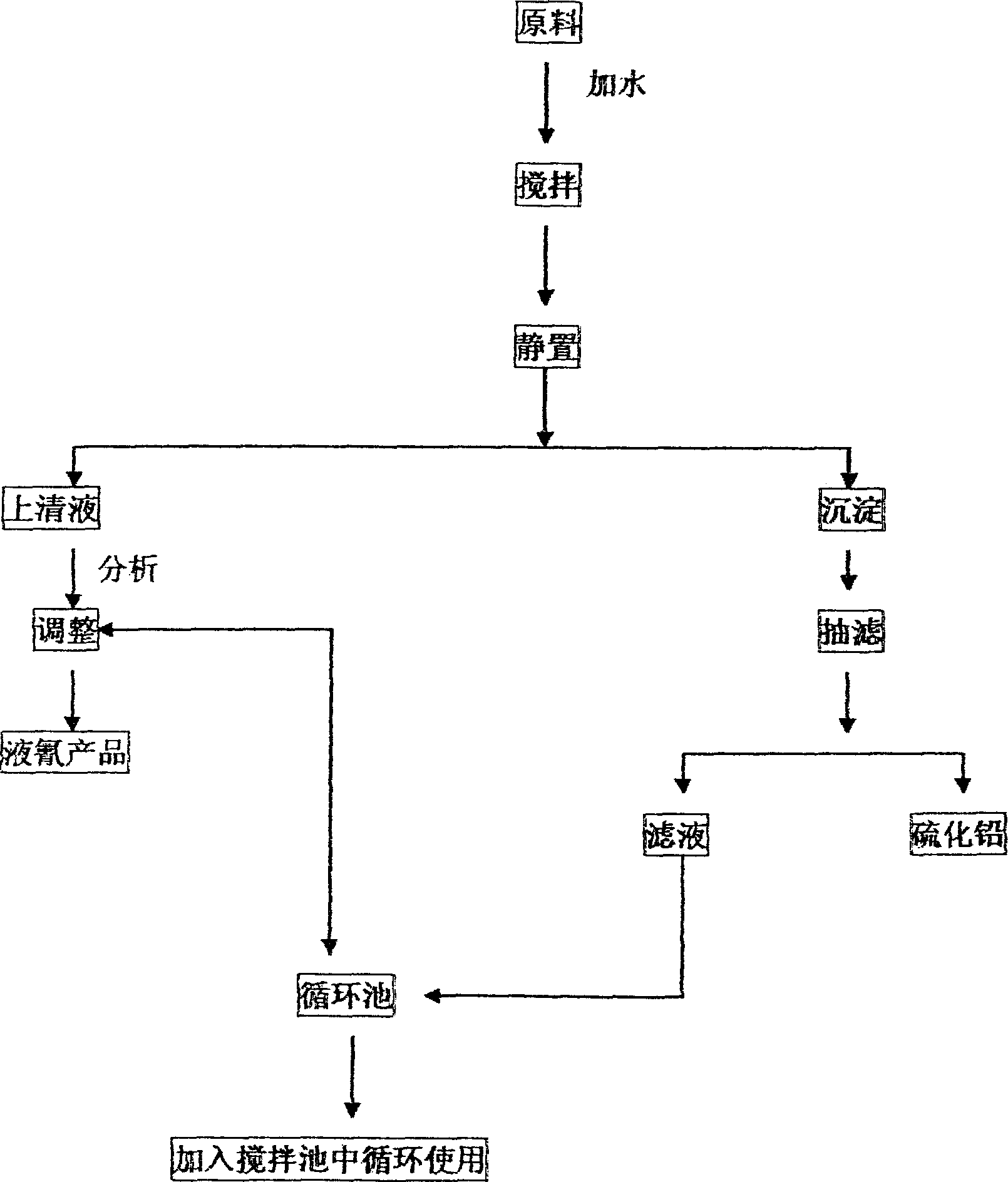

Image

Examples

Embodiment

[0014] 1. Raw materials:

[0015] shape

[0016] 2. Experimental process:

[0017] (1) Add 400 g of raw materials into the beaker, add 400 g of deionized water and stir for 1 hour, then let stand for 12 hours, filter the supernatant and analyze that the NaCN content is 17.8%;

[0018] (2) Add 400 g of deionized water to the sediment in the previous step, stir for 1 hour and let stand for 12 hours, filter the supernatant and analyze that the NaCN content is 8.6%;

[0019] (3) Repeat the above steps (1) and (2) 3 times;

[0020] (4) Wash the lead sulfide residue in the cup to the sand core funnel. The funnel is connected to the suction filter bottle and vacuum pump in advance, and the sediment in the funnel is repeatedly washed and the filtrate is collected for analysis until the NaCN content is <0.5PPm and meets the environmental protection requirements;

[0021] (5) Take new raw materials and repeat the above process, change the deionized water added in the last te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com