Ore dressing combination process for processing high-slime lead-zinc oxide and sulfide mixed ore

A combined process and mixed ore technology, applied in the directions of flotation, solid separation, wet separation, etc., can solve the problems of non-selectivity of particle size, partial sliming of fine particle, serious problems, etc., and achieve good economic benefits and stable operation. , the effect of high technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

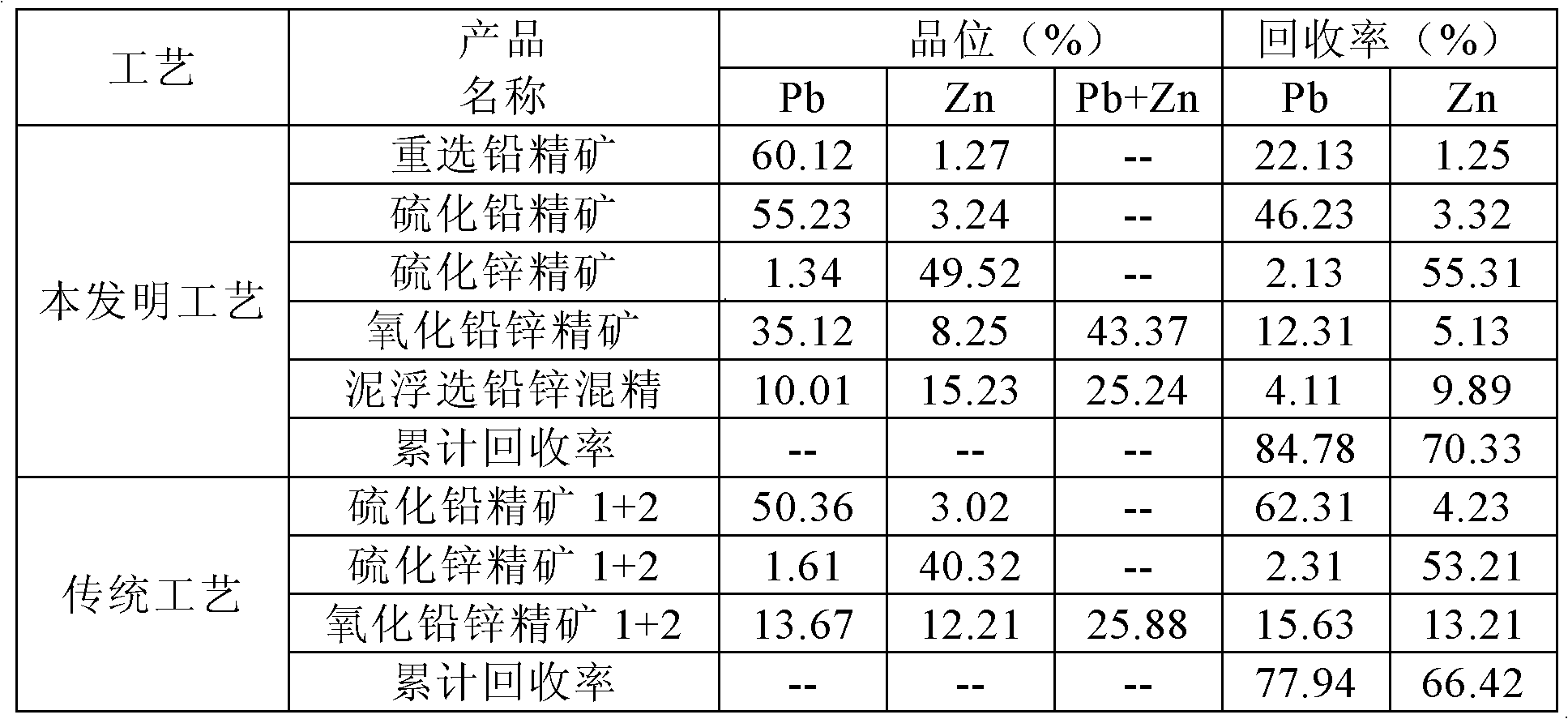

[0028] In this embodiment, the high-mud lead-zinc-oxygen-sulfur mixed metal ore in Huize, Yunnan is selected, and the ore is mainly ore of useful minerals galena, white leadite, sphalerite and smithsonite. The content of lead and zinc in lead oxide and zinc minerals accounts for 25wt% and 30wt% of the total lead and zinc contents of the minerals respectively. In addition to these useful minerals composed of beneficial elements, there are also a large number of gangue minerals dolomite, calcite, Clay minerals and a small amount of quartz. The lead content in the ore is 4.5wt%, zinc 4.8wt%.

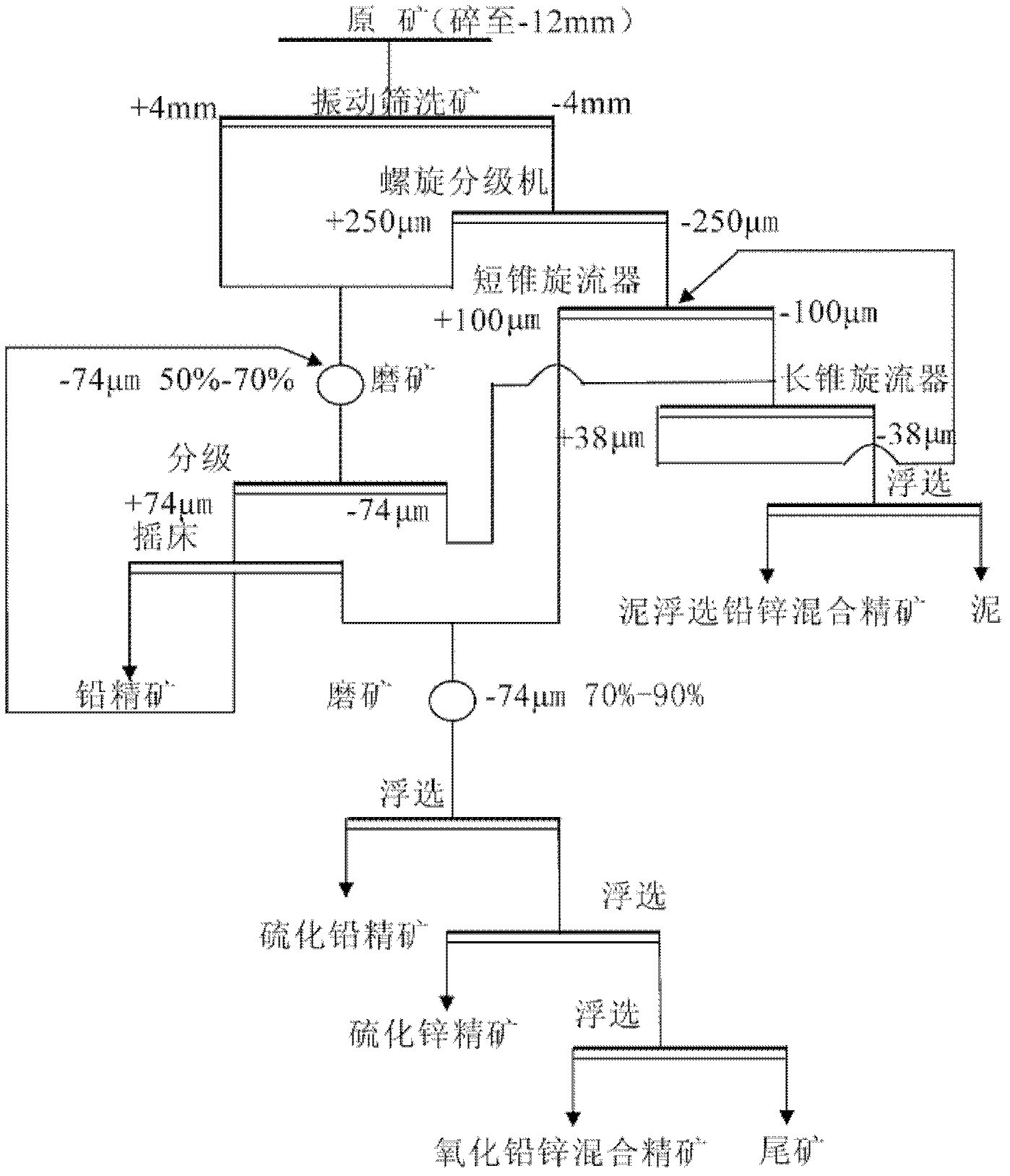

[0029] Utilize the method of the present invention, be about to wash raw material ore first with the vibrating screen that sieve hole is 4mm, the part under the sieve adopts the spiral classifier that classifying granularity is 250 μm to carry out primary classification, and the fine-grained grade part is separated through the short cone swirling flow that granularity is 100 μm The long co...

Embodiment 2

[0034] The high-mud lead-zinc-oxygen-sulfur mixed metal mine in Huize, Yunnan, ores are mainly useful minerals galena, white lead ore, sphalerite, sphalerite and smithsonite. The content of lead and zinc in lead oxide and zinc minerals accounts for 28wt% and 30wt% of the total lead and zinc contents of the minerals respectively. In addition to these useful minerals composed of beneficial elements, there are also a large number of gangue minerals dolomite, calcite, Clay minerals and a small amount of quartz. The lead content in the ore is 4.8wt%, zinc 5.3wt%.

[0035]Utilize the method of the present invention, be about to wash raw material ore first with the vibrating screen that sieve hole is 4mm, the part under the sieve adopts the spiral classifier of 250 μm of grading particle size to carry out primary classification, and the fine-grained part is separated by the short cone cyclone with particle size of 100 μm and a long cone cyclone with a separation particle size of 38 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com