Modified asphalt, method for preparing modified asphalt and nanometer reaction adhesive waterproof roll

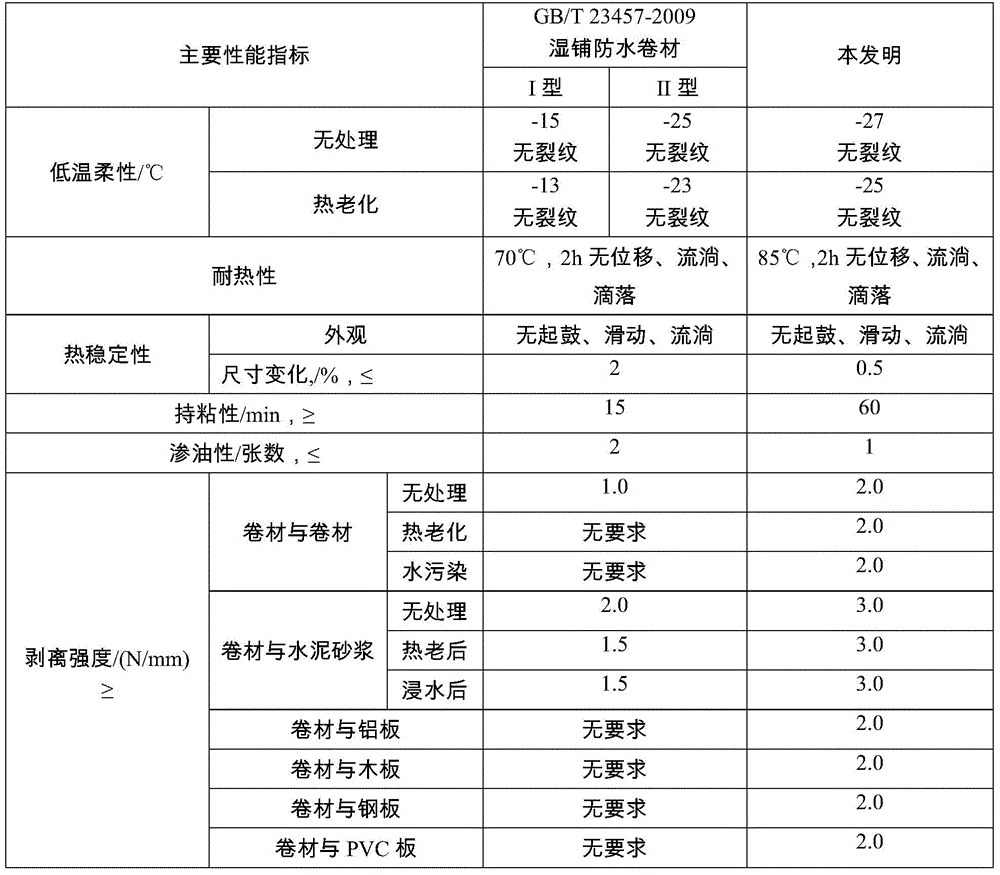

A technology of modified asphalt and petroleum asphalt, which is applied in the direction of asphalt layered products, chemical instruments and methods, building insulation materials, etc., and can solve problems such as waterproof layer sliding, poor high temperature resistance, and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of modified asphalt of the present invention, comprises the steps:

[0040] Add the petroleum asphalt into the mixing tank, stir and heat up to 150°C;

[0041] Adding the nano-silica and the nano-zeolite into the stirring tank, stirring at 150-160° C. for 1.5-2.5 hours to obtain a mixture;

[0042] The mixture is sheared and ground for 1 to 1.5 hours through a colloid mill at a temperature of 150-160°C and a rotational speed of 2900-3600r / min.

[0043] Preferably, the step of adding the petroleum asphalt into the stirring tank also includes adding a softener and a tackifier to the stirring tank; adding the nano silicon dioxide and the nano zeolite to the stirring tank It also includes adding a thermoplastic elastomer into the mixing tank.

[0044] The addition of the thermoplastic elastomer, softener and tackifier can improve the comprehensive performance of the modified asphalt.

[0045]The present invention also provides a nano-reactive adhes...

Embodiment 1

[0052] Each raw material is prepared as follows by weight parts:

[0053] Petroleum pitch: 100 parts,

[0054] Nanoparticles: 36 parts,

[0055] Thermoplastic Elastomer: 18 parts,

[0056] Softener: 14 parts,

[0057] Tackifier: 6 parts.

[0058] The petroleum pitch is No. 70 petroleum pitch, the nanoparticles are nano silicon dioxide and nano zeolite, and the thermoplastic elastomer is styrene-butadiene-styrene block copolymer and styrene-isoprene -Styrene block copolymer, the softener is aromatic hydrocarbon oil, and the tackifier is petroleum resin C5, petroleum resin C9 and rosin glyceride resin.

[0059] Wherein, the weight ratio of nano-silica and nano-zeolite is 2:1; the weight ratio of styrene-butadiene-styrene block copolymer and styrene-isoprene-styrene block copolymer is 13 :5; the weight ratio of petroleum resin C5, petroleum resin C9, rosin glycerol resin is 17:20:14.

[0060] Add the petroleum asphalt, softener and tackifier into the stirring tank, stir and...

Embodiment 2

[0063] Each raw material is prepared as follows by weight parts:

[0064] Petroleum pitch: 100 parts,

[0065] Nanoparticles: 40 parts,

[0066] Thermoplastic Elastomer: 20 parts,

[0067] Softener: 15 parts,

[0068] Tackifier: 8 parts.

[0069] The petroleum pitch is No. 90 petroleum pitch, the nanoparticles are nano silicon dioxide and nano zeolite, and the thermoplastic elastomer is styrene-butadiene-styrene block copolymer and styrene-isoprene -Styrene block copolymer, the softener is naphthenic oil, and the tackifier is petroleum resin C5, petroleum resin C9 and rosin glyceride resin.

[0070] Wherein, the weight ratio of nano-silica and nano-zeolite is 2:1; the weight ratio of styrene-butadiene-styrene block copolymer and styrene-isoprene-styrene block copolymer is 13 :5; the weight ratio of petroleum resin C5, petroleum resin C9, rosin glycerol resin is 17:20:14.

[0071] Add the petroleum asphalt, softener and tackifier into the stirring tank, stir, heat up to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com